Using car headlight sealant

Many people do not know what is the best sealant to use for headlights of the car, if there is a need for repair. It is impossible to use sanitary and other options. It is necessary to choose a special composition, it will provide quality gluing or caulking damage. There are several varieties on sale, so it is worth understanding their features to determine which type is suitable in a particular situation.

Types of headlight sealants

Compounds differ first of all by the raw material from which they are made. This determines their properties and provides certain characteristics. Most often in stores there are variants of 4 types, it is worth dissecting each of them separately.

Polyurethane compositions

Polyurethane provides high strength after curing. Most often it is used for gluing cracks and damages. Some even glue whole pieces of glass if you need to drive urgently. The main features of this variety are as follows:

- High adhesion to smooth surfaces. The sealant adheres perfectly to the glass and does not fall off under the influence of vibrations, temperature fluctuations and other adverse factors.

- The composition is impermeable to moisture, so it protects the headlight from its penetration and prevents fogging of the glass from the inside.

- Service life is at least several years. And if applied qualitatively, polyurethane sealant can retain its properties for decades.

- Repairs can be carried out even when the air temperatures are not the highest. Because of this, if necessary, it will not be difficult to glue the headlight directly on the street if there is no garage or the glass was damaged on the road.

- After curing, polyurethane mass is not afraid of oil, fuel, alcohol-containing liquids, road reagents, etc.

Due to its fluidity even small parts can be glued.

The main disadvantage is its low temperature resistance. If the headlights get very hot, you should not use polyurethane sealant. It is also not safe for human health before it cures, as it emits dangerous fumes.

Anaerobic options

This group of products has its own characteristics and is used in some cases where its properties are suitable:

- The product has a liquid consistency, which imposes certain restrictions on its application.

- It is used in small damages, where compositions of another type simply will not penetrate. You can carefully fill the crack and thereby strengthen it or seal a tight joint.

- Protective equipment is not needed at work. The compound is carefully applied in the right place, after which the elements should be pressed tightly to each other and held that way for a while.

High fluidity creates problems during repair. You need to dose the fluid very accurately and make sure that it does not leak and ruin the reflector or other elements of the headlight.

Heat Resistant Sealants

This solution is distinguished by its high strength, after polymerization, the composition can withstand temperatures up to 400 degrees or even higher. Such extreme durability is necessary for headlights, which get very hot during work and are switched on very often. But apart from the heat resistance, this type has other advantages:

- The cured mass is highly durable and long-lasting. It does not lose its plasticity for years and provides a reliable connection of both the same and different materials.

- It does not flake under constant vibration, well withstands moderate deformation loads. Technical and other aggressive liquids do not spoil the mass and do not degrade its properties.

- Most often it is a two-component compound, which is prepared before application. It can be both malleable and quite hard. Due to this feature, the shelf life of the sealant is long, because it does not harden until a hardener is added to the composition.

By the way! After application, you need to leave the headlight for at least 8 hours so that the polymerization took place and the finished mass seized well. Therefore, the repair is best done at night or when there is time to spare.

Silicone Compounds

The basis of manufacture of this group of products are natural or synthetic rubbers. Due to this the mass is plastic and resembles a dense rubber after hardening. Most often the composition has additives for protection against ultraviolet radiation. But such variants do not tolerate the impact of technical fluids, especially alcoholic ones. When choosing, you need to pay attention to this point. The features are as follows:

- This is the cheapest type of compositions, so they are used most often. Silicone-based sealant can be purchased at any auto store.

- The adhesive properties are high and the consistency is thick enough to securely fasten the headlights to the body. Silicone is easy to apply, it does not flow and does not set immediately, allowing you to set the optimal position and fix the glass.

- Heat resistance is different, usually it ranges from 100 to 300 degrees. It is better to pick up the index with a reserve, to exclude any problems.

The advantage of silicone can also be called that, if necessary, to separate it is much easier than other types. It does not harden too much and cuts well with a sharp knife, which makes it easier to remove the glass if it is needed later.

What to look for

Not all sealants are equally reliable. When buying, you need to remember a few tips to choose a quality option that is suitable for a particular type of work. It is worth considering such factors:

- Adhesion to a certain type of material. It is necessary to know what surfaces will be glued in order to choose the solution that will ensure reliable attachment and avoid damage to the adhesive layer.

- Resistance to vibration.. During the operation of the car, its elements vibrate. Therefore, the sealant should become not only durable, but also elastic after curing.

- Heat resistance .. This is especially true for headlights, in which xenon or other strongly heated bulbs are installed. There must be a certain reserve of temperature resistance, otherwise the layer will eventually dry out and does not provide the necessary reliability.

- The volume of the composition in the container. Here it is worth to proceed from how much sealant is required for the normal performance of the planned work. It is necessary to take with a reserve, as the actual consumption is almost always higher than planned.

- Easy removal from surfaces. This applies both to cleaning the elements on which the sealing mass got and disassembly of the headlamp, if it may be required later.

- Color of compound. If you need to seal a crack or damage to the glass, then a transparent version will do, it will be invisible after curing. For gluing the glass to the body, the color does not matter much, because the joint is hidden.

It is better to give preference to products from the medium and high price segment. Its quality corresponds to the declared and defects are almost never encountered. In the cheap segment, there is no guarantee that the sealant will provide the necessary reliability.

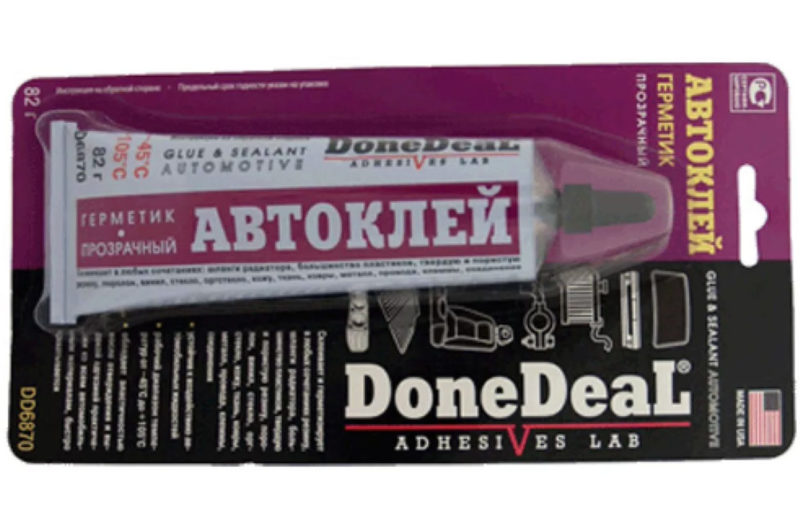

We recommend that you take a look.

How to use the compound correctly

Even the highest quality version will not provide the proper reliability, if the technology of the work was violated. Therefore, it is necessary to follow a few simple tips in order to achieve a good result:

- The remains of the old composition, if any, must be removed. This is done mechanically using degreaser or other means.

- The surfaces to be glued should be well cleaned of dust and dirt and degreased. If they are smooth, it may be necessary to sand them with sandpaper to improve adhesion.The surface should be cleaned and degreased before bonding.

- The instructions for use of the sealant should be read carefully before starting work. Be guided by the manufacturer's recommendations to avoid any problems and get the desired result.

- After bonding parts should be secured with clamps or other devices to prevent parts from shifting during curing of the sealant. The curing time recommended by the manufacturer must be adhered to.

You can use a construction hair dryer or any other heat source to accelerate the curing time.

Popular Headlight Sealants

There are many options, but some of them are in high demand, as they have been repeatedly tested in practice and have proven their quality:

- 3M PU 590. Polyurethane mass from a serious manufacturer. Suitable for gluing headlights and any other elements in the car. Packaged in tubes of 300 and 600 ml, can be used as a sealant anywhere. Cures in just 40 minutes.

- Dow Corning 7091. It is a transparent, silicone-based compound which is very suitable for gluing glass to the car body. It creates a flexible and durable joint that is impervious to moisture and UV-resistant. Available in different packages, it is odorless, which simplifies the application. Cures up quickly enough.

- Abro WS 904. This sealant is not available in a tube, but as a thin bundle coiled into a roll. In order to glue the glass to the body, you need to degrease the surface, tear off a piece of suitable length and heat the elements well with a hair dryer. After cooling, you get a strong seam, resistant to adverse influences.This option is easy to use and does not stick to your fingers.

To well glue headlight glass or seal cracks in the surface, you need to choose a high-quality and safe composition. It is equally important to study the instructions on the package to do the job correctly.