How to make a 12 volt power supply with your own hands - sample circuits

12 volt DC voltage source - a useful device for home, cottage or garage. Such a device is not difficult to make yourself. Below is a diagram of a 12V power supply for assembly with their own hands, as well as tips on calculation and the selection of components.

Types of power supplies

To date, pulsed voltage sources are widespread. Before traditional transformer circuits, they have a significant advantage in energy efficiency and in mass-size indicators. It is believed that with load currents over 5 amps they have an undeniable advantage. But they also have disadvantages, such as the generation of RF interference into the mains supply and into the load. And the main obstacle for home assembly is the complexity of circuits and the need for special skills for making winding parts. Therefore, it is better for an average home handyman to make a power supply on the usual principle with a mains step-down transformer.

Where the voltage source is used

The scope of application of such a PSU in the household is wide:

- powering low-voltage lamps;

- Rechargeable batteries charging;

- Power supply for audio playback devices.

As well as many other purposes for which a constant voltage of 12 volts is required.

Diagram of a transformer power supply

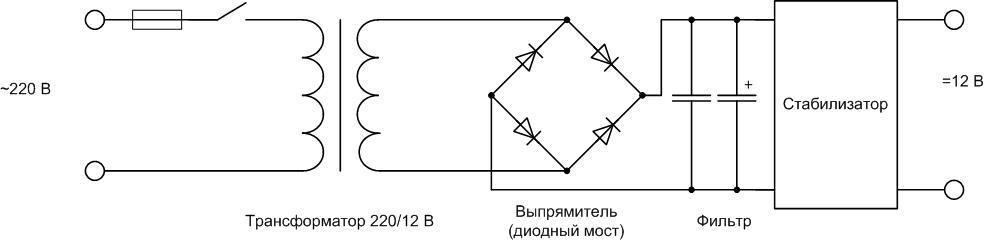

Schematic diagram of a 12 volt power supply operating from a 220 V network, consists of the following nodes:

- A step-down transformer.. It consists of iron, primary and secondary (there can be several of them) windings. Without going into the principle of operation, it should be noted that the output voltage depends on the ratio of the primary (n1) and secondary (n2) windings. To get 12 volts, it is necessary that the secondary winding contains 220/12=18.3 times less turns than the primary winding.

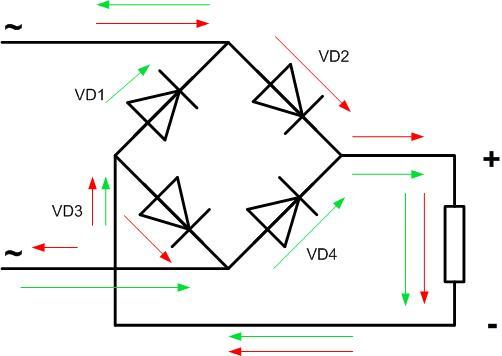

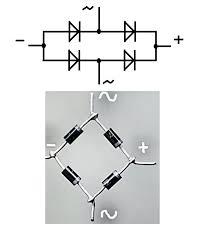

- Rectifier. Most often made in the form of a two-half-period circuit (diode bridge). Converts alternating voltage into pulsating voltage. The current passes through the load twice per period in the same direction.Operation of a half-period rectifier.

- Filter. Converts the pulsating voltage into a direct voltage. It is charged at moments of applied voltage, and discharged at pauses. It consists of a high-capacity oxide capacitor, in parallel with which a ceramic capacitor with a capacity of about 1 µF is often included. To understand the need for this additional element, it is necessary to remember that the oxide capacitor is arranged in the form of strips of foil rolled up in a roll. This roll has a parasitic inductance, which noticeably degrades the quality of high-frequency noise filtering. For this purpose, an additional short-circuit capacitor of the HF pulses is included.Equivalent filter circuit with oxide and additional capacitors.

- Stabilizer. May not be present. Schemes of simple but effective assemblies are discussed below.

In the following sections, the procedure for selecting and calculating each element of a 12 volt DC voltage source is discussed.

Transformer Selection

To obtain a suitable transformer two ways are possible. Making the step-down unit yourself or selecting a suitable factory-assembled transformer. In either case you should keep in mind:

- at the output of the step-down winding of the transformer when measuring the voltage, a voltmeter will show the effective voltage (1.4 times less than the amplitude voltage);

- at the filtering capacitor without load DC voltage will be approximately equal to the amplitude voltage (they say that the capacitor voltage "rises" in 1.4 times);

- if there is no stabilizer, then under the load the voltage on the capacitor will sag depending on the current;

- for stabilizer operation a certain excess of input voltage over the output voltage is necessary, their ratio limits the efficiency of the power supply unit as a whole.

From the last two points it follows that for normal operation of the PSU the transformer voltage must exceed 12 V.

Independent winding of a transformer

The complete calculation and fabrication of a homemade power transformer is complicated, time consuming, and requires tools and skills. Therefore, we will consider a simplified way - the selection of a suitable iron unit and its conversion to 12 V.

If there is a ready-made transformer, but there is no diagram of its connection, it is necessary to call its winding with a tester. The winding with the highest resistance is likely to be the mains one. The other windings must be removed.

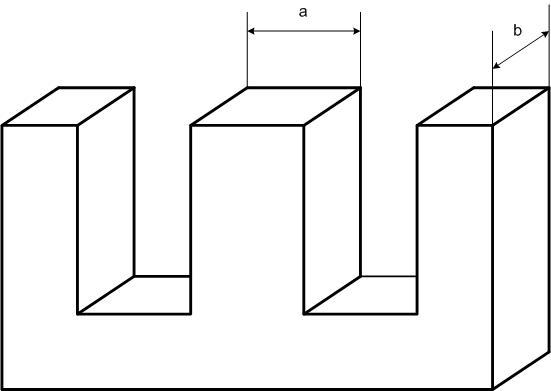

Next, you should measure the thickness of the iron set b and the width of the central plate a and multiply them. You will get the cross sectional area of the core S=a*b (in sq.cm.). This determines the power of the transformer P=. Next, the maximum current in amperes that can be drawn from the winding with a voltage of 12 volts is calculated: I=P/12.

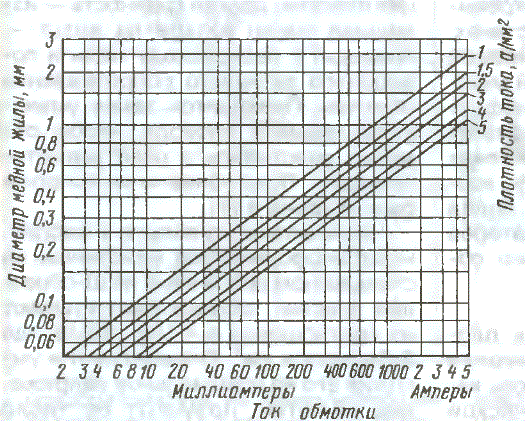

Then the number of turns per volt is calculated according to the formula n=50/S. For 12 volts you should wind 12*n turns with about 20% reserve for losses in copper and stabilizer. And if there is no stabilizer, then the voltage drop under load. And the last step is to choose the cross section of the winding wire according to the chart for a current density of 2-3 ma/sq.mm.

For example, there is a transformer with a 220V primary winding with a set of iron 3.5 cm thick and a mid-tongue width of 2.5 cm. So S=2.5*3.5=8.75 and the transformer power =3 W (approximately). Then the maximum possible current at 12 volts I=P/U=3/12=0.25 A. For winding you can choose a wire with diameter 0,35...0,4 sq.mm. For 1 volt there are 50/8,75=5,7 turns, you need to wind 12*5,7=33 turns. With the reserve - about 40 turns.

Selection of the finished transformer

If there is an off-the-shelf transformer with a suitable secondary winding for current and voltage, you can try to pick up an off-the-shelf transformer. For example, in the TPP series there are suitable products with a secondary voltage close to 12 volts.

| Transformer | Designation of the secondary winding outputs | Voltage, V | Allowed current, А |

| TPP48 | 11-12, 13-14, 15-16, 17-18 | 13,8 | 0,27 |

| TPP209 | 11-12, 13-15 | 11,5 | 0,0236 |

| TPP216 | 11-12, 13-14, 15-16, 17-18 | 11,5 | 0,072 |

The advantage of this solution is the minimum labor intensity and reliability of the factory design. Minus - transformer contains other windings, the overall power is calculated for their load. Therefore, such a transformer will lose out in terms of weight and dimensions.

Choosing diodes and making a rectifier

Diodes in the rectifier are selected according to three parameters:

- The highest permissible forward voltage;

- Highest reverse voltage;

- The highest operating current.

According to the first two parameters, 90 percent of the available semiconductor devices are suitable for operation in a 12-volt circuit, the choice is mainly made according to the maximum continuous allowable current. This parameter also determines the design of the diode body and the way the rectifier is made.

If the load current will not exceed 1 A, you can use foreign and domestic single-amp diodes:

- 1N4001-1N4007;

- HER101-HER108;

- KD258 ("drop");

- KD212 and others.

Devices KD105 (KD106) are designed for smaller currents (up to 0.3 A). All listed diodes can be mounted vertically or horizontally on PCB or mounting plate, or just on pins. They do not need radiators.

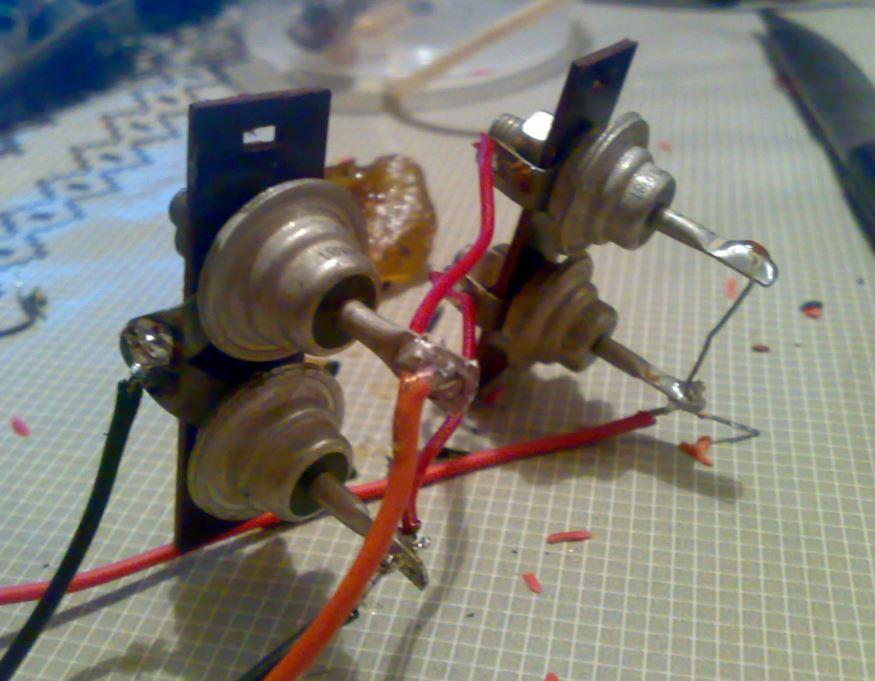

If you need high operating currents, you should use other diodes (KD213, KD202, KD203, etc.). These devices are designed for operation on heat sinks, without them they will withstand no more than 10% of the maximum rated current. Therefore, it is necessary to pick up ready-made heat sinks or make them yourself from copper or aluminum.

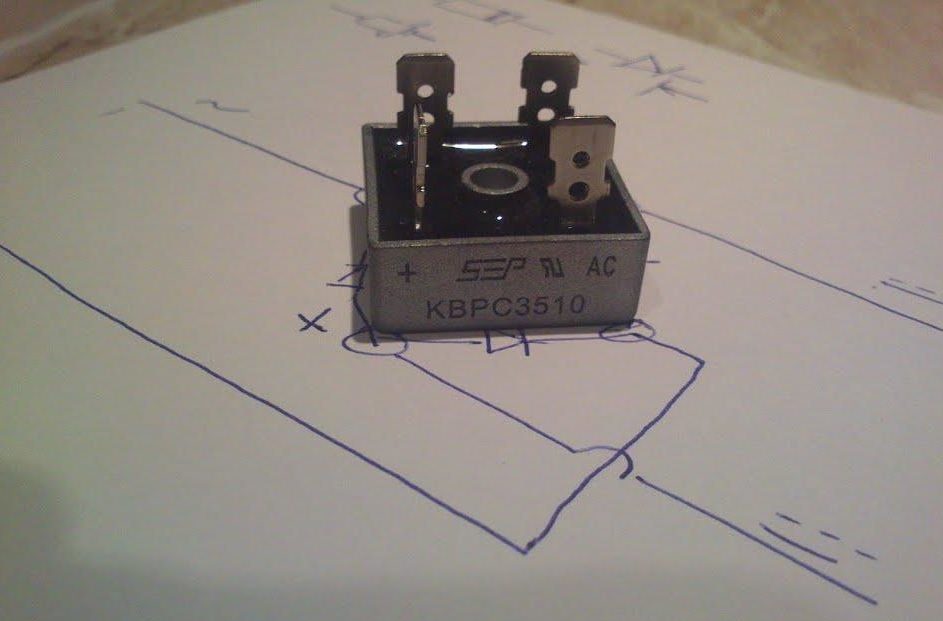

It is also convenient to use ready-made bridge diode assemblies KTs405, KVRS or similar. You don't have to assemble them, just connect AC voltage to the corresponding pins and remove DC voltage.

Capacitor Capacity

The capacitor capacity depends on the load and the ripple it allows. There are formulas and online calculators that can be found on the Internet to accurately calculate capacitance. For practice, you can go by the numbers:

- For small load currents (tens of milliamps) the capacitance should be 100...200 μF;

- at currents up to 500 mA a 470...560 uF capacitor is needed;

- up to 1 A - 1000...1500 uF.

For higher currents, the capacitance increases proportionally. The general approach is that the bigger the capacitor, the better. You can increase its capacity to any limits, being limited only by the size and cost. In terms of voltage, it is necessary to take a capacitor with a serious reserve. For example, for a 12-volt rectifier, it is better to take a 25-volt element than a 16-volt one.

This reasoning is true for non-stabilized sources. If you have a PSU with a regulator, the capacitance can be reduced many times over.

Stabilizing the Output Voltage

It is not always necessary to regulate the output of a power supply. For example, if you intend to use a PSU with audio equipment, you must have a stable voltage at the output. But if a heater is used as a load a stabilizer is obviously unnecessary. For LED strips can do without the most complex module of the PSU, but on the other hand, a stable voltage ensures independence of brightness at fluctuations in the network and extends the life of the LED-lighting.

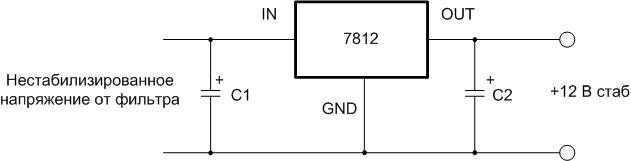

If the decision to install a regulator is made, it is easiest to assemble it on a specialized LM7812 chip (KR142EN5A). The circuit is simple and does not require any adjustment.

You can supply voltages from 15 to 35 volts to the input of such a regulator. A capacitor C1 with a capacity of at least 0.33 μF should be installed at the input and at least 0.1 μF at the output. As C1 usually acts as a capacitor of the filter unit, if the length of the connecting wires does not exceed 7 cm. If it is not possible to maintain such a length, a separate element will have to be installed.

The 7812 chip has protection against overheating and short circuits. But it does not like the polarity reversal on the input and the external voltage on the output - its lifetime in such situations is counted in seconds.

Important! For a load current over 100 mA installation of the regulator on the heat sink is mandatory!

Increasing the output current of the regulator

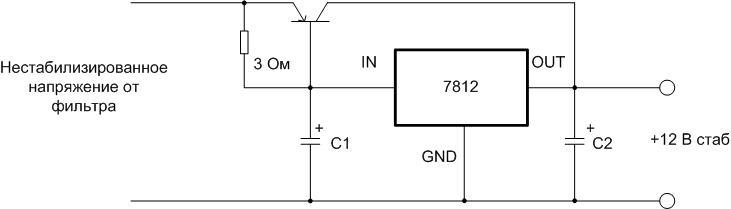

The given scheme allows to load the AVR with a current up to 1.5 A. If this is not enough, you can recharge the node with an additional transistor.

Scheme with n-p-n transistor

This circuit is recommended by the designers and is included in the datasheet for the chip. The output current must not exceed the maximum collector current of the transistor, which must be equipped with a heat sink.

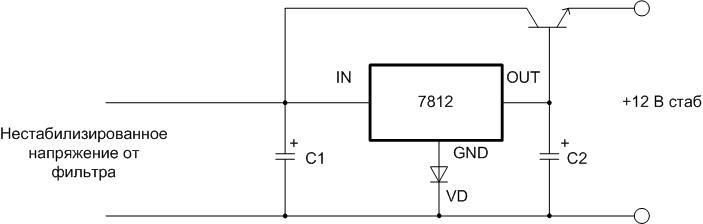

Circuit with a p-n-p transistor

If a semiconductor triode of n-n-p structure is missing, you can recharge the stabilizer with a semiconductor triode of p-n-p structure.

A low-power silicon diode VD increases the output voltage of 7812 by 0.6 V and compensates for the voltage drop across the emitter junction of the transistor.

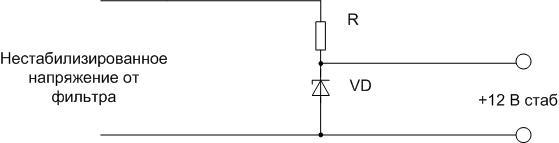

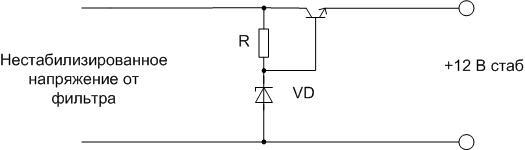

Parametric regulator

If for some reason an integrated regulator is not available, you can make a node on a regulator. It is necessary to select a regulator with stabilization voltage of 12 V and designed for the corresponding load current. The maximum current for some 12 V domestic and imported regulators is given in the table below.

| Stabilized diodes type | D814G | D815D | KS620A | 1N4742A | BZV55C12 | 1N5242B |

| Load current | 5 mA | 0,5 А | 50 mA | 25 mA | 5 mA | 40 mA |

| Stabilization voltage | 12 volt | |||||

The rating of the resistor is calculated by the formula:

R= (Uin min-Ust)/(In max+Ist min), where:

- Uin min - minimum input unstabilized voltage (should not be less than 1,4 Ust), volts;

- Ust - stabilized voltage of the regulator (reference value), volts;

- In max - maximum load current;

- Ist min - minimum stabilization current (reference value).

If there is no stabilitron for the desired voltage, it can be composed of two in series. The total voltage should be 12 volts (for example, the D815A at 5.6 volts plus the D815B at 6.8 volts will give 12.4 volts).

Important! It is not allowed to connect stabilitrons (even of the same type) in parallel "to increase the stabilizing current"!

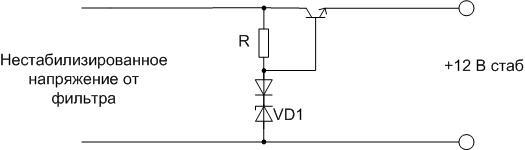

You can recharge a parametric AVR in the same way - by connecting an external transistor.

A heatsink should be provided for the power transistor. The supply voltage in this case will be 0,6 V less than Ust of the stabilizer. If necessary the output voltage can be adjusted upwards by including a silicon diode (or a chain of diodes). Each element in the chain will increase U out by about 0,6 V.

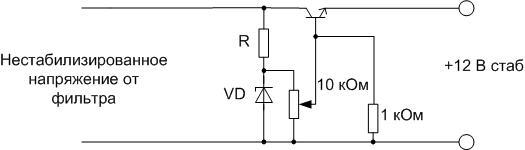

Regulating the output voltage

If the voltage of the power supply needs to be regulated from zero, a parametric regulator with the addition of a variable resistor is the best scheme.

A 1k ohm resistor between the transistor base and the common wire will protect the triode from failure if the potentiometer slider circuit breaks. When you turn the knob of the variable resistor, the voltage at the base of the transistor will change from 0 to Ust stabilizer with a lag of about 0.6 volts. It should be kept in mind that the parameters of the node will be worse due to the use of a potentiometer - the presence of a moving contact (even a good quality one) will inevitably reduce the stability of the transistor base voltage.

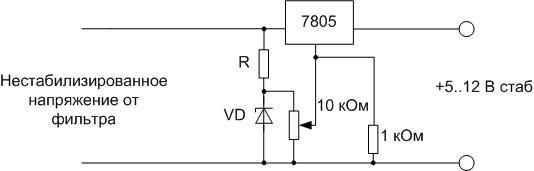

Achieving 0 to 12 volt regulation of a circuit with a 78XX series integrated regulator is much more difficult. If you have enough regulation range from 5 to 12 volts, you can use a 7805 chip and connect it to a potentiometer circuit. The stabilitron should be about 7 volts (KC168 with or without a diode, KC175, etc.). In the lower position of the potentiometer slider the GND pin is connected to the common wire, and the output will be 5 volts. When the slider is shifted to the upper pin the voltage on it will rise up to Ust of the stabilizer and add to the stabilization voltage of the microcircuit.

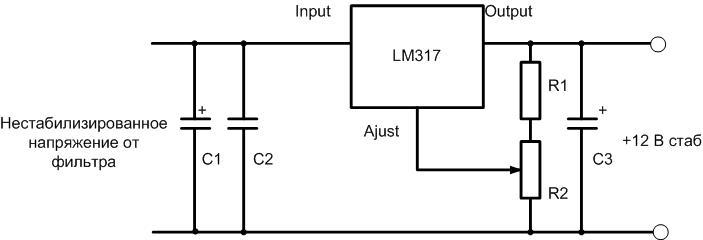

You can use an LM317 chip. It also has three pins and is specifically designed to create regulated sources. But this regulator has a lower voltage threshold starting at 1.25 volts. There are many LM317 circuits on the internet with zero regulation, but 90+ percent of these circuits are inoperable.

Read also:Homemade 0 to 30V voltage and current regulated power supply

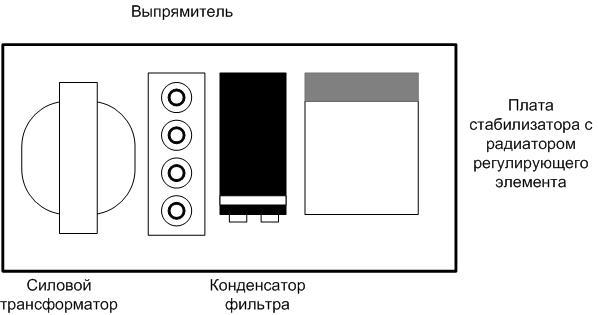

Device layout

When all the parts are selected or you have a clear idea of what they will be, you can start to assemble the circuit. It is also important to understand what the future housing of the device will be. You can pick up ready-made, you can make it yourself if you have the materials and skills.

There are no special rules for the layout of the nodes inside the enclosure. But it is desirable to arrange the nodes so that they are connected by wires in series, as in the diagram, and by the shortest possible distance. It is best to place the output terminals on the side opposite to the mains cable. The power switch and fuse are better placed on the back of the unit. In order to rationally use the space between the enclosures, some of the nodes can be mounted vertically, but it is better to fix the diode bridge horizontally. If mounted vertically, convection currents of hot air from the lower diodes will flow around the upper elements and heat them additionally.

For those who don't understand, watch this video: Simple Power Supply with your own hands.

It is not difficult to assemble a DC power supply with a fixed power supply. This is within the power of an average craftsman, requiring only a basic knowledge of electrical engineering and minimal installation skills.