Wiring the lighting in the garage with their own hands

You can make lighting in the garage without using specialists to save money. The work is not complicated, it can be sorted out in just a few hours. To assemble a safe and reliable system, you must comply with the basic requirements of the Rules for Electrical Installations (PUE) and make a detailed project, which specifies the location and characteristics of all elements.

General requirements

The basic information on the device of wiring in garages is contained in section 2.1 PUE, but in other chapters there are important data that will be required when working. For simplicity, the most important points are gathered in this section:

- Wiring can be done in a variety of ways. If the surfaces are non-combustible (bricks, blocks, metal, etc.), you can use the open method. To do this, choose a cable with a reinforced sheath. For walls and ceilings covered with wood and other flammable materials, it is obligatory to use non-combustible corrugation or cable ducts.It is possible to lay the open wiring in non-combustible corrugations.

- You can use both copper cable (VVG) and aluminum cable (AVVG) for the arrangement of the system. The first option is preferred because it has less resistance, bends better and lasts longer. Variants of type SHVVP or PVS should not be taken, they must be used for portable installations, and for stationary power are not suitable.

- Cross-section of the cable strands to choose on the basis of the load it must withstand during use. It is best to select options with a margin, for the garage are often used copper cable cross section of 2.5 mm2 or 4 mm aluminum cable.2.

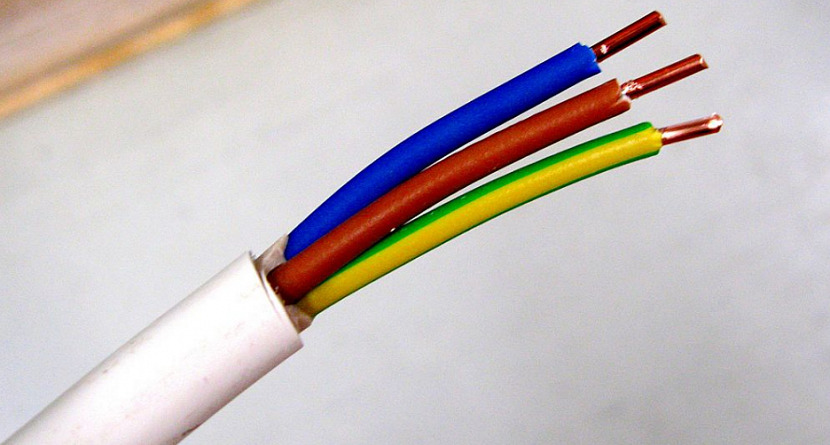

- According to modern requirements of electrical safety in the garage must make grounding. It should be provided on the circuit diagram, and when purchasing cable choose three-core versions if the network is single-phase or five-core versions if three-phase.Cable for single-phase loads with a grounding conductor.

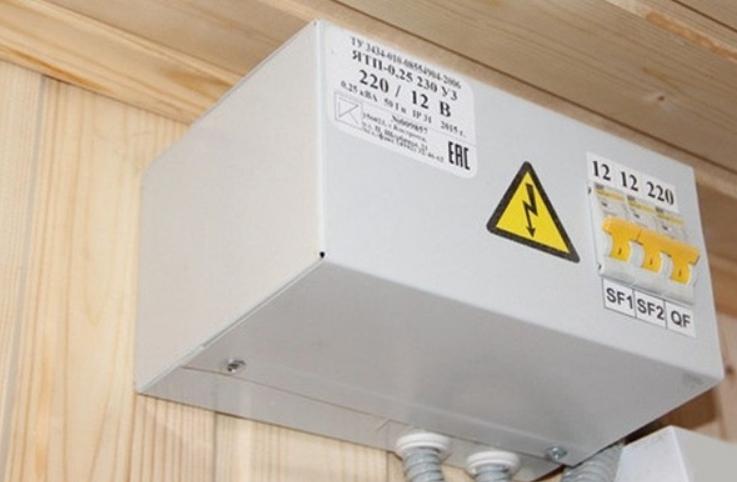

- Safety regulations prohibit the use in the garage, and especially in the observation pit of portable devices that operate from 220V. In this case, you need to buy a LED lamp that runs on 12 V. It can be powered from the car battery, but it is better to install a stationary step-down transformer, to which you can connect any equipment that operates from 12 volts.When using low voltage, a step-down transformer is added to the system.

- For lighting choose luminaires with degree of protection IP65 or higher and should work well in humid and dusty environments. Select a sealed lamp cover that will provide protection even at sub-zero temperatures.

- Sockets should also be chosen with protection against moisture, they must be earthed. Ideally, choose closed structures that prevent moisture or foreign objects from getting inside.When selecting outlets, carefully look at the degree of protection.

- The cable must be routed strictly vertically or horizontally. Diagonal mounting to reduce the angle is not allowed. Crossings and bends at an acute angle are forbidden.

- Before you conduct and connect electricity must agree to work with the management of the garage cooperative (if any). There to clarify what documents will be required.

- The minimum indentation from the ceiling when laying cable on the wall - 10 cm, from the apertures and communications must be observed at least 15 cm.

- Light should be distributed evenly, there should be no dark corners and uneven lighting. Choose equipment with diffused light so that it does not strike the eyes.

- It is better to provide different options for turning on the light so that you don't have to use all the equipment all the time. Ideally, localized areas (e.g., above the workbench), so they can be wired separately.

By the way! If a street light will be installed in front of the garage entrance, it is worth to equip it with a motion sensor to light up and turn off automatically.

Types of light sources

When choosing a lamp or other light source, you need to pay attention to several points: the safety of the equipment, working life, protection from moisture and dust, resistance to temperature fluctuations. So it is necessary to evaluate all the pros and cons of each type and make the right decision.

Types of lamps

Different options are suitable for the garage, but it is necessary to take into account the conditions of use and features of the structure. Based on them, you can choose one of the listed types:

- Incandescent bulbs used to be placed in all garages, but today they are rarely used due to high electricity consumption and low life expectancy. Incandescent filament gives poor quality light and distributes it unevenly. Lights for the garage are most often bulky because of the large diffuser and massive housing. They get very hot during operation, which creates additional hazards.An example of incandescent lighting

- Halogen bulbs - are advanced products with a tungsten filament and an inert gas pumped into the bulb. The light from them is much brighter, but the electricity consumption is also high. During operation, the surface is strongly heated, so be sure to need a plafond, this type does not tolerate shocks, voltage fluctuations, dust, so it is not suitable for the garage. A plus is the possibility of using low-voltage lamps, working from the voltage of 12 V through the power supply.

- Fluorescent lamps They provide bright light without consuming a lot of power. They can be in bulb form or in a compact version for a standard socket. Suitable only for heated garages, because at temperatures below 5 degrees they do not work well and fail quickly. Another drawback is the mercury vapor inside, which evaporates into the air if the bulb is damaged.

- LED bulbs and lights consume the least amount of electricity and give even light without flicker. You can choose different color temperatures, which is also important for comfort. For good visibility, it is better to choose cool tones that provide bright uniform lighting. Instead of lamps, you can use fixtures or LED strips, which can serve as backlighting or full lighting of individual areas.LED lighting is the safest and most economical to date.

You can combine different options, if it gives a good result. But If possible, it is better to equip the garage with low-voltage LED lightingto ensure safety. A good lamp in the garage on the LED is more expensive, but due to the savings in electricity and long life will eventually cost less.

Lighting inspection pit

This part of the garage is distinguished by the most difficult conditions of the lights, so you need to select the equipment carefully. To make a safe and durable system, you should follow a few tips:

- Choose fixtures with moisture and dust protection class IP67. This is the most reliable option that can withstand even a jet of water and works with heavy air pollution. Information on protection class can be found on the packaging or in the documentation to the luminaire.Luminaires with moisture protection.

- It is worth using only versions whose lamps are not heated during operation. During repair, you can accidentally touch the surface and get burned. It is better if the glass or diffuser is plastic and the surface is protected by a metal or polymer frame.

- For safety, you should only use low-voltage lighting that runs on 12, 24, 36 or 50 volts. The best solution - LED equipment, as it is not afraid of damp, shock and operates at a minimum voltage, while the quality of light will be excellent.

- Place the lights should be approximately at shoulder level, it is good if there is a niche for this purpose in the pit, so it is much more convenient to put and fix the equipment. Since you need to direct the light in different places, you can put LED spotlights - for the garage is a great solution that will illuminate the exact part of the bottom of the machine that you need.

- Be sure to take care of the carrier as well, with it you can illuminate any place. Better if it is a version in a shockproof case with a hook to hang it wherever you need it. The light should also work from a low-voltage line.A great option is an LED light strip.

- You can use an LED strip to illuminate the pit. In this case, you need a moisture-protected version in a silicone shell. It is better to choose a cold white light, the number to calculate by the size of the pit. Most often the tape is attached on both sides along the entire length.

The step-down transformer for the pit must necessarily be taken out of its limits. Usually it is put in the switchboard, but you can equip a small cabinet nearby, in which to place the equipment.

Calculation of the number and power of lamps

Norms of lighting is in SNIP 23.05.95. To avoid going through the documents, it is easier to highlight the main points and in accordance with them to determine the right number of luminaires and their location:

- For simplicity, to use the norm for lighting the garage in lux (this figure is equal to 1 lumens per square meter). If the garage for repair work, the minimum norm - 200 lux, when the room just put the car, 50-100 lux will suffice. When working for a long time (more than 4 hours a day) should provide illumination of at least 300 lux, and for painting and bodywork - 500 lux and above.

- For each type of lamp there is data on the luminous flux, and on LED it is indicated on the packaging. To calculate the illumination rate for a garage, you need its The area in square meters multiplied by 200.. For example, if the room 4x5, then 20x200 = 4000 lux. On average, a 10 watt LED version gives a luminous flux of 700 Lm, so you will need 6 light sources (rounded upwards).

- It is better to use two less powerful lights instead of one - the more even the light, the better. Therefore, it is worth thinking in advance about the location of the equipment, based on the features of the garage and its size.

- With a large width of the garage is better to place lights on the ceiling with an indentation of at least 50 cm from the wall, from each other rows should not be less than a meter. If the height of the ceiling is high, additionally fix the lighting elements on the walls at a height of 150 cm from the floor.The location of lighting fixtures should be selected individually for each garage.

- If the ceilings are low, you can do with only wall lightsIf the ceilings are low, you can make do with wall lights only, distributing them evenly on the walls. The work area should be illuminated with either equipment located below eye level or put plafonds that can be adjusted if necessary.

- The illumination of the inspection pit should be planned on the basis of the norm of 200 lumens per square meter. Arrange evenly so there are no dark areas. You can additionally make illumination on the steps to secure the movement.

By the way! To see what is on the floor and safely exit the car, you can also make a light at a level of 40 cm from the floor.

How to do the work

To do everything correctly, it is necessary to follow the step-by-step instructions and perform it step by step. Then there will be no problems and it will not be difficult to understand the process. All work is important, if you miss a point, then you will have to redo the system or even re-lay it.

Preparing

It is necessary to start long before the work is done. First of all, get all the necessary permits and deal with the connection to the power line. It is also necessary to prepare a tool for the work, its set depends on the method of laying the cable. It is important to remember the following:

- First of all, make a project. In it to provide for all the important points: the place of installation of the electrical switchboard, the location of junction boxes, light fixtures and outlets. Also determine how the cable will be laid, where best to place the step-down transformer and other lines, if any.

- Buy lightsLights, sockets, switchboard and other components - circuit breakers, RCDs, junction boxes, transformer, etc. Also buy the necessary section of cable, take with a reserve, since you need to leave the ends for connection, and the actual flow may be a little more than the plan.

- Also buy everything you need to lay the cable. If it will be placed openly, you need cable channels or special brackets. If it will be laid covertly, you will need a corrugated sleeve that is laid along the entire length of the cable lines.

- Determine connection method. If you need to wire separately, an overhead line or underground cable laying option is used. In garage cooperatives, electricity is usually routed through the top of the garage and a branch line must be made.

If you need to make strokes, you will need a punch with a concrete trowel and a grinder with a stone disk.

Wiring

It is best to do concealed wiring, to eliminate any risk of damage to the cable and hide it from adverse influences. The work is carried out as follows:

- Mark out the lines of laying, it is easiest to make marks on the walls to have a clear reference point in front of your eyes. Remember the norms and lead the cable strictly vertically or horizontally.

- If open wiring will be used, secure the cable duct with self-tapping screws or dowel nails, depending on the type of wall. Cut corners at 45 degrees, so that the joints are clear and do not expose the cable.

- In the concealed version, make a hole of such size that the corrugated sleeve will fit there. The easiest way is to make cuts with a bolt cutter and then knock it out with a drill.Example of laying in a joint.

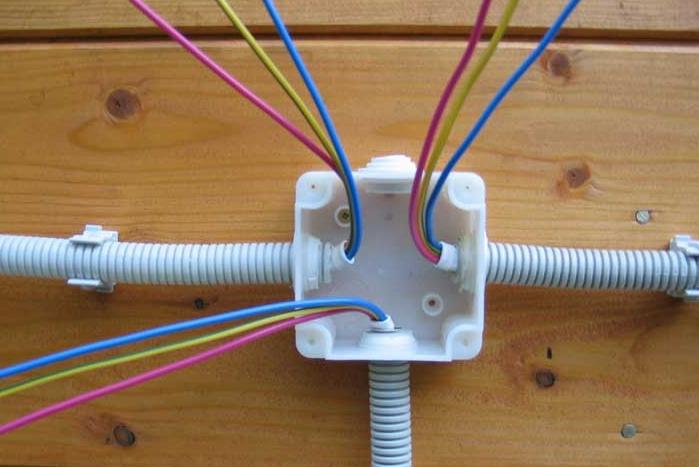

- To lay the cable. Make connections with the help of pads. If stranded strands are used, they should be soldered and placed in heat shrink tubing.All branching shall be done through junction boxes.

- After laying, close the cable-channel or putty filler to hide the place of laying, leave the wires in the right places.

- Particular attention should be paid to the wiring that goes into the inspection pit. It must be hidden and well waterproofed. The ideal solution is to lay it when pouring the screed.

- Fix the lights and sockets in the places where they are located. Choose a mounting method depending on the type of equipment and the surface on which it is installed. Pay special attention to the contacts, they must be reliable and well insulated.

There are special wiring connectors that provide a tight joint.

Installation of the starter panel

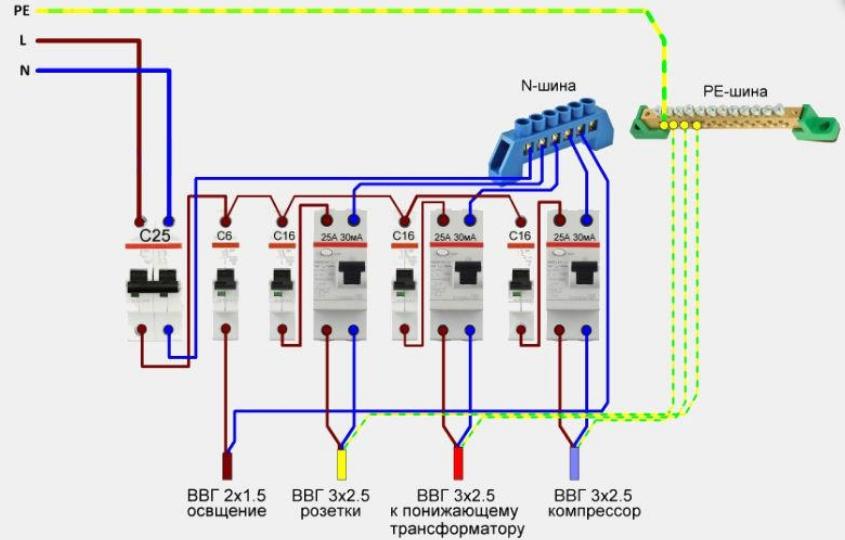

This is the main element from which all lines in the garage, so it must be done qualitatively, do not skimp on components. The work is carried out as follows:

- A switchboard is fixed, it is best to put it near the entrance for the convenience of switching on and off.

- First of all, put the input automatic circuit breaker, which will be responsible for the supply of electricity. If necessary, set the counter.

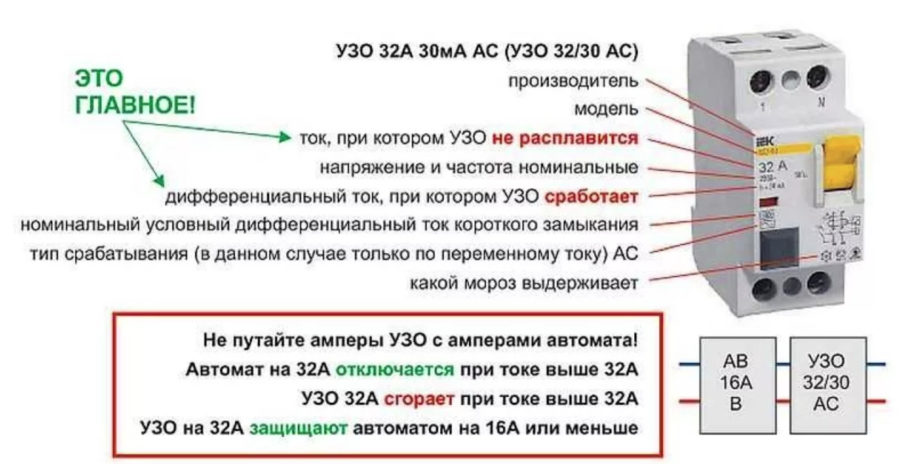

- Next, it is necessary to put the line fuse. Here everything is done according to the scheme, selected models of suitable capacity. Also, for each automatic circuit breaker is set RCD for protection against short circuits, it must switch both phase and zero.

- Put a step-down transformer, it is also easier to locate in the panel.

By the way! Do not forget about the ground loop, it should be done when installing wiring.

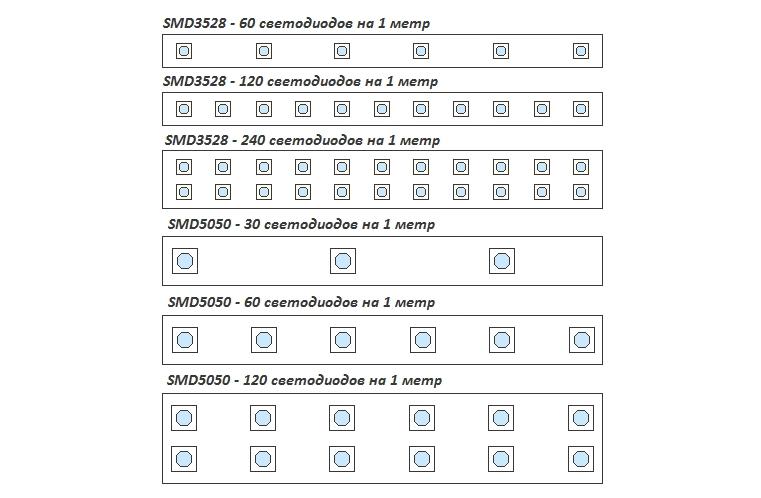

Budget way of lighting with LED strip

If you do not want to bother with wiring and installing fixtures, you can make a safe low-voltage lighting, which is enough to power a single switch or socket. First of all, you will need a sufficient number of LED strips (you need to know the characteristics of a single diodeto divide by this figure required power, the result will be the number of diodes that will be needed).

Diodes can be placed on a strip with different frequencies, the more of them - the better. Choose options with cool white light. Colored strips RGB better not to take, because their light characteristics are an order of magnitude lower than in monochrome.

For power you can buy a ready-made module, but you can adapt the power supply from a computer to make the project even cheaper. You will also need wires for connection, connectors or a soldering iron for connections contacts.

Step by step instructions

To carry out the work on the power of even those who have minimal experience in electricity. To make a light in the garage using tape, it is necessary to follow a few simple recommendations:

- Choose the location of the LED strip. Good for beams, or any flat surfaces. If the ceiling or wall is crooked, it is worth fixing on it an even bar or aluminum profile to be the basis for the future lighting system. It is easier to fix the tape on a beam or other not very smooth wooden element. If you first glue the construction double-sided adhesive tape on a foam base - it will ensure reliable installation.

- LED strip Cut it in a suitable place (it's marked on the surface) and carefully glue it on, gradually removing the protective film from the back. If double-sided tape was used, remove the protective layer from it, the tape is attached very firmly to such a base.Places for cutting on the LED strip is additionally marked with a dotted line or scissor icon.

- If one line of diodes is not enough, you can fix two or even three. Due to this quality light is provided, so as not to put lights. Next, you need to solder the wires or connectors. Connect each strip separately, if you connect them in series, the light will be dim. All connections should be soldered and placed in a heat shrink tube to protect them from moisture.

- Wires should be led to the location of the power supply, and they can be attached to the walls with clips or special clamps. If you are using computer power supplies, you should calculate the necessary amount by their power. It is easier to put a ready-made version, through which the light is connected.

If there are reflector lights in the garage, you can glue tape in there to increase the intensity of the light.

In conclusion, a thematic video:

Wiring the light in the garage is not difficult if you understand the topic, make a detailed diagram and lay the wiring in accordance with the PUE. It is best to use LED lamps or strips, as they operate from low voltage, consume little electricity and have a long life.