Replacing the cartridge in the lamp with your own hands

To change the bulb in the chandelier you can do yourself, for this you do not need to call an electrician. The main thing - to understand the peculiarities of work and study the design of the main types of equipment. If you follow the recommendations for the work, any danger is excluded, and the result will be no worse than that of professionals.

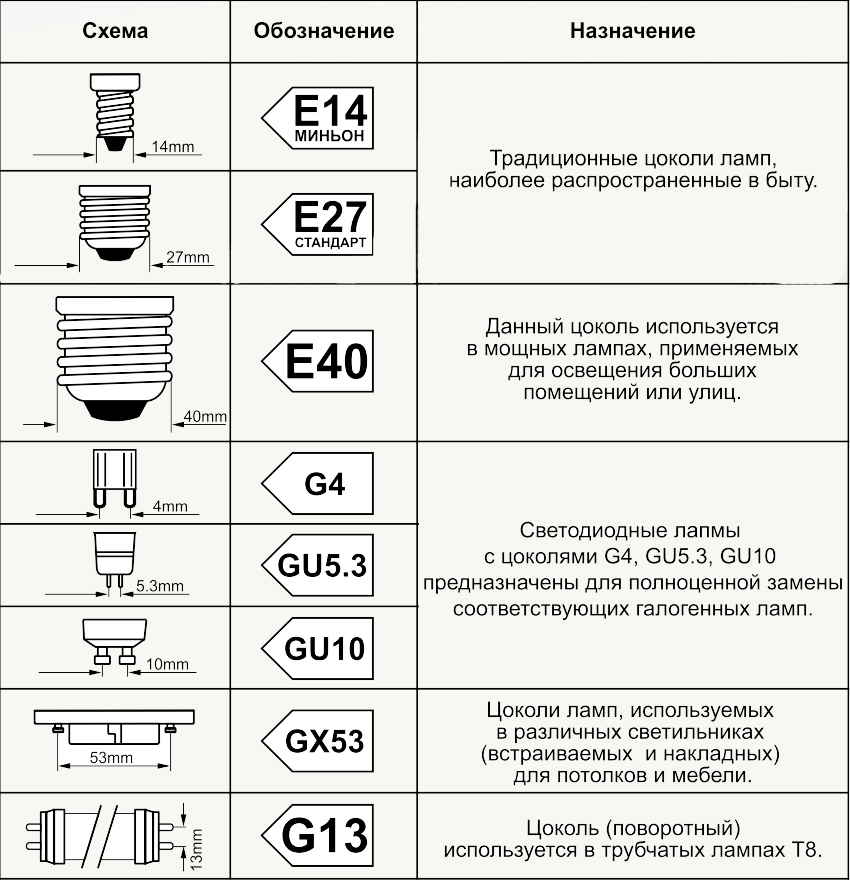

Varieties and marking of chandelier sockets

Currently several variants are used, each has its own characteristics. We can distinguish two main groups: screw (denoted by the letter E) and pin (marked by the letter G).

Requirements for threaded cartridges are prescribed in GOST R MEK 60238-99. There are three basic varieties:

- E14, it is also called "Mignon". Diameter of 14 mm, is designed to connect incandescent light bulbs of low power and almost all LED light sources, as they consume little electricity. The main option in most modern chandeliers and lamps. The maximum allowable power is 440 W with a load current of up to 2 A.The E14 socket is much narrower than the standard E27 version.

- Е27. The Edison round threaded socket with a diameter of 27 mm, until recently was the basic and used in almost all chandeliers. Standard solution, familiar to everyone, suitable for ordinary incandescent bulbs and any other options. Designed for power up to 880 W, the maximum load current should not exceed 4 A.A clear comparison of the two varieties.

- Е40. The variant with a thread diameter of 40 mm is used for high-power street lighting. It can use lamps up to 3500 W at a load current of up to 16 A.

Technical requirements for sockets of pin type are specified in GOST R MEK 60400-99. All products of this type must comply with the technical regulations from the document. The main varieties are:

- G4, G5.3, G6.35, G8, G10. All modifications of pin cartridge have the same design, only the distance between pins differs. The number indicates the distance in millimeters, which allows you to navigate the design features. The maximum power of the bulbs should not exceed 60 W, the load limitation is 4 A.Lamp with GU5.3 base

- G9. This variant uses LED and halogen lamps with flat contacts. In this case the technical indicators are the same as in the products above.

- GU10. The system is similar to the usual pin sockets, but in this case the diameter of the contacts is increased. Installation is carried out not only due to the tight arrangement of contacts, the bulb is rotated clockwise and firmly fixed in the socket. It is possible to install elements up to 60 W with a load current of up to 5 A.GU10 socket in the luminaire.

- G13. Modification for linear lamps, when inserting the lamp it is necessary to turn it by 90 degrees to fix it. The peculiarity is that the replacement of the base in the chandelier or lamp is made in pairs, as each light source has 2 elements. Designed for lamps up to 80 W with current up to 4 A.Luminaire with G23 socket

For suspended and stretch ceilings, a special GX53 socket is available in a small thickness, which is suitable for limited space.

Material

Heat-resistant plastic or ceramic is used for the production of sockets. Each option has its own characteristics, with the polymer type they are:

- Plastic products are inexpensive. But at the same time from constant heating, the material eventually becomes brittle and begins to break down. It can also become deformed, especially if the quality of raw materials is not very good.

- Elements are not difficult to disassemble and replace. White variants inevitably turn yellow over time, indicating that it is time to replace them.

Ceramic cartridges are less common, but are in demand because of the following features:

- A metal retaining nut is always used on the inside, because the ceramics stick when heated for a long time and are difficult to remove.

- If the base does stick to the threaded part because of the heat, it is unscrewed together with the sleeve. This allows you to disassemble the socket for the bulb quickly.

- The heat resistance of this option is an order of magnitude higher than that of plastic, but the price is also higher.

Reasons for replacing the socket

The work should be carried out in the following cases:

- If there is visible damage or cracks on the element. Another option - the plastic has become brittle and it showed signs of severe overheating.

- When you turn on the light, the bulb does not work, even though there is nothing wrong with it. Usually this is due to severe corrosion of the central contact or threaded part. It is not worth grinding them, it is wiser to immediately put a new part.

- The bulb base is stuck and can't be unscrewed out of the threaded part. It is better not to apply too much force, as the bulb may burst. It is easier to change the socket.

- Damage to the terminals, their deformation, which leads to short circuits in the structure.

By the way! Experts advise to change sockets for preventive purposes at least once every 5 years, This will prevent any problems and ensure the safety of the equipment.

The process of replacing the cartridge in the chandelier

First of all, you need to collect the necessary tools:

- Regular and indicator screwdrivers. It is better to have several variants for different types of fasteners.

- Electrician's knife.

- Several pieces of wire. Preferably, the same as in the chandelier.

- Terminals or a soldering iron to connect the wires.

- Duct tape.

Replacing the socket consists of several steps:

- The power supply at the switchboard is turned off. Most often there is a separate circuit breaker for the lighting. You need to check and find the one that is responsible for the lights. Check by turning on the light or other equipment operating on the same line.Before working with electrical appliances, turn off the power at the switchboard.

- Next, make sure that the chandelier is not energized. To do this, use an indicator screwdriver. Even with the circuit breaker turned off, it is necessary to do this to rule out any problems. Only after checking, you can continue to work.Measure the voltage on all suitable wires indicator should not shine.

- Carefully unscrew the cover that covers the fixing place under the ceiling and disconnect the wires. Most often they are connected via a socket, in older houses it can be a twist, wrapped with electrical tape. It is desirable to replace it with a normal connection later, it is easier and safer. Disconnected wires are bred to the sides to eliminate the possibility of a short circuit.It is best to connect to the wiring with a special block.

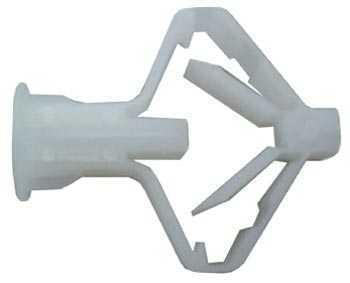

- If the chandelier has fragile and easily removable elements, they should be removed first. If the design hangs on a hook, it must be carefully removed, it's simple. When the lamp is fixed to a plate, it must be unscrewed, most often a screwdriver or a small wrench is needed there. On stretch ceilings use a special fixture, which is called a "butterfly", when you remove it, it is advisable to put a new one, it is worth buying in advance.Fixture "Butterfly"

For mounting fixtures on suspended ceilings. - If the chandelier is hot due to prolonged work, it is necessary to let it cool down. Then remove the plafonds (here it all depends on how they are attached) and decorative elements that create a hindrance to the work.

- Light fixtures are removed in different ways, it all depends on how they are mounted. Most often they are held by threads or a large pressure ring, which must be carefully unscrewed. Sometimes the elements are fixed on small bolts, then they are simply unscrewed. After disassembly, the clamping screws of the wires are loosened and they are disconnected.

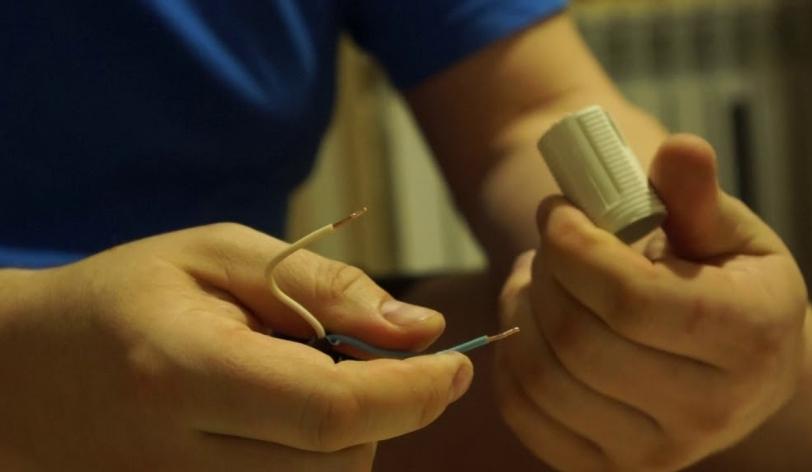

- Changing the socket in the lamp is not difficult, the work is carried out in reverse order. First, wires are connected to the new unit, this is done with terminals or clamp screws with plates, the main thing is to avoid contact of wires and their short circuit. Then the socket is put in place and fixed. Then you can put the lamps and connect the chandelier to the wiring, pre-hanging it on the ceiling.

By the way! In the LED chandelier bulb can not be replaced, there will have to re-solder the diodes, which is much more complicated.

This video shows how to properly disconnect and remove a damaged socket.

How to disassemble the socket correctly

When the threaded part stuck, the easiest way to unscrew the sleeve of the socket together with the bulb, it will greatly simplify the process. If there is nothing wrong with the assembly, you need to inspect the mount and work on its type.

Most often you just need to unscrew the upper part from the base, then gently pull out the ceramic insert and disconnect the wires. There are options with a nut that presses the element to the body of the plafond, it is carefully unscrewed after disassembly.

In new fixtures there is a variant when the socket is pressed with a screw on the side, in this case you just need to unscrew it and extract the part outside.

From the video you will learn: How to correctly disassemble a socket made of plastic with a snap-on cover.

Replacing the cartridge with your own hands is not difficult. The main thing is to observe safety precautions and carry out the work according to simple instructions. It is important not to damage the seat in the chandelier, there are no other restrictions.