How to remake a LED bulb

Inexperienced craftsman may seem that the eternal LED light bulb with their own hands - this is too difficult a task. But the instructions do not contain complex processes, special knowledge in electricity is also not needed. The only thing that is required from the master is attentiveness, preparation of the workplace, the right choice of components and a set of tools at hand.

To make a perpetual LED lamp, it is recommended to use high or medium power chips. It makes sense to start work only if there are no problems with wiring, because network instability can cause diodes or drivers to burn out, regardless of their quality.

What is a perpetual LED light bulb

None of the manufacturers produce LED bulbs with the loud name "eternal". Quality products can last up to 50,000 hours, but only if there are no problems with the wiring and reliable assembly elements that will help overcome overheating, if it happens. To extend the service life, the master can replace the components with more expensive ones, which will not allow the diodes to burn out even after 5-6 years.

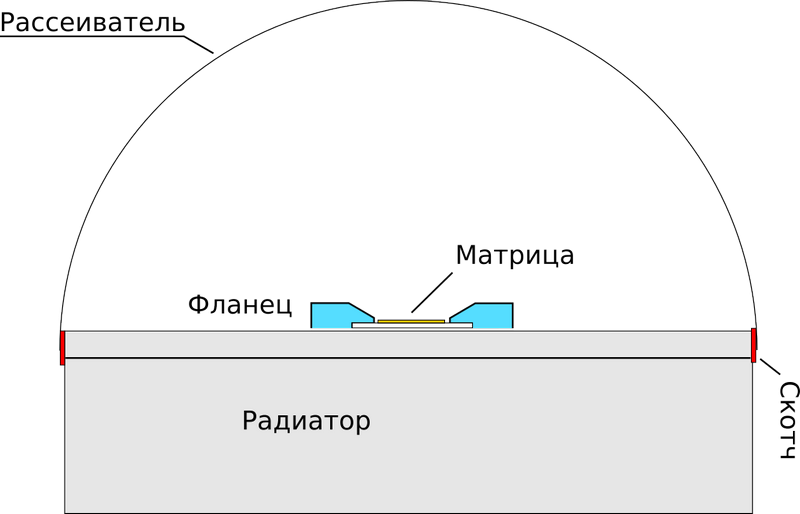

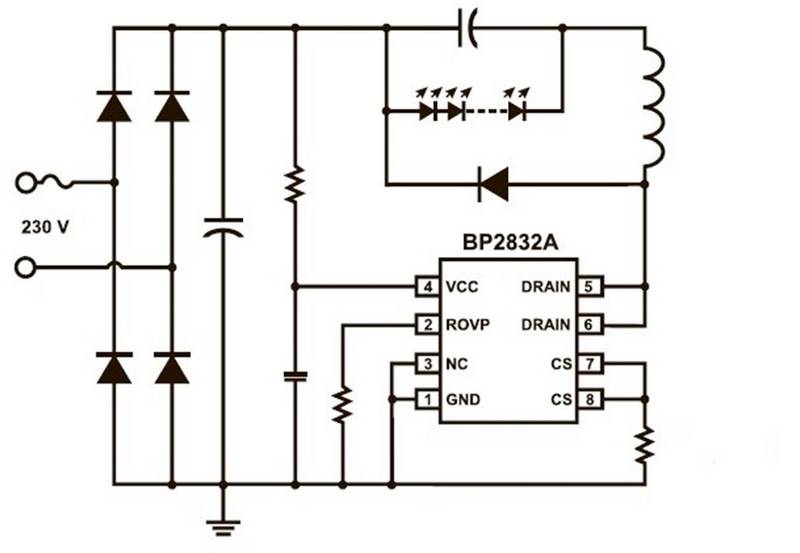

In order to get an eternal LED lamp, first of all you should deal with the cooling system. It is on this many manufacturers save money, which violates the temperature regime and LEDs burn out. Also often suffers from the electronic filling of the device. The design might look like the picture below.

To assemble this light fixture, you will need experience. Therefore, a novice craftsman is better suited to remake a purchased LED lamp. A perpetual lamp can be considered a product with elements replaced by more powerful and efficient.

What bulbs are suitable for remaking

In order for the remade lamp to serve for a really long time, it is better to take a known-quality model. For example, products from the following manufacturers:

- Osram;

- Philips;

- Gauss;

- ASD;

- Camelion.

It is worth considering the models of Russian companies, as they are already adapted to the local power grid and are therefore more resistant to voltage fluctuations.

What you need to convert the LED light bulb into a perpetual

To work, you should have:

- a holder;

- glue;

- knife;

- soldering iron with a thin sting;

- new diodes (if they are to be replaced);

- a resistor of higher resistance;

- posistor for soft turn-on;

- tweezers;

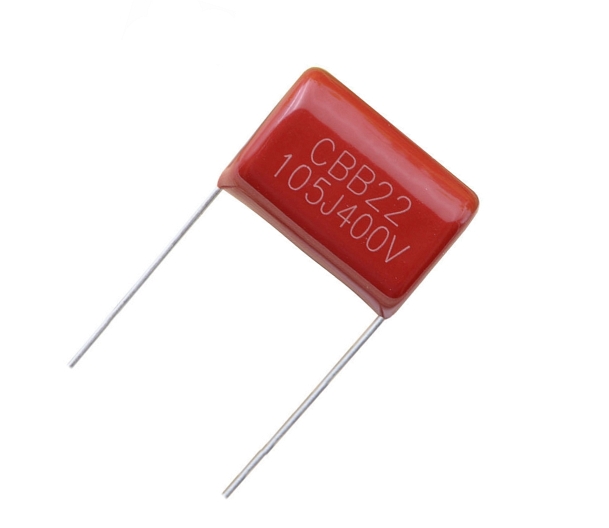

- capacitor.

The last element of the assembly is needed to dissipate heat, the excess of which reduces the life of all components of the lamp. The capacitor is installed between the plate with LEDs and the base, and is selected depending on the power of the bulb.

Article on the subject: How to disassemble and repair the LED bulb

Step by step instructions for remaking light bulbs

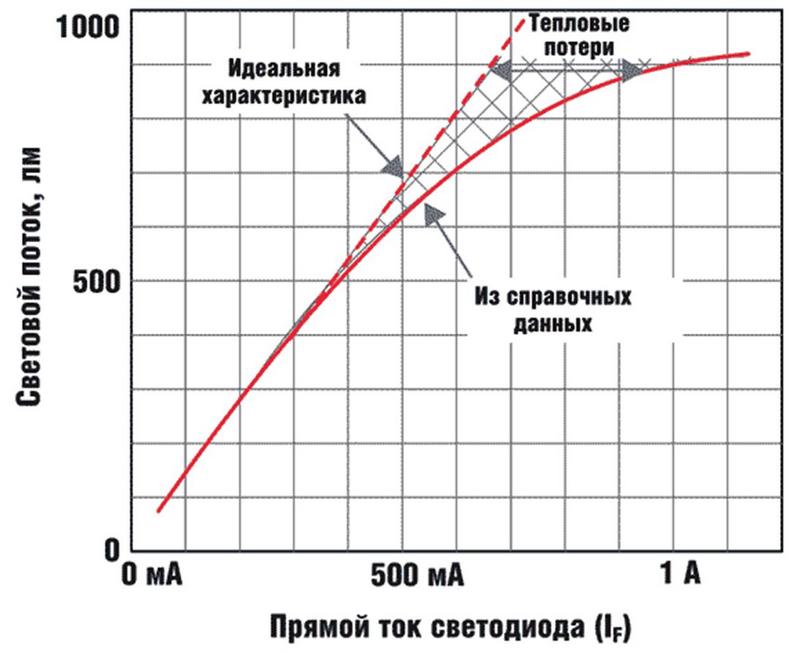

At the first stage of remodeling it is necessary to reduce the current through the LEDs. This will extend the life of the product. But the brightness characteristics will also be reduced. The decrease in parameters is not linear, but with a lag. At the same time, the efficiency of each chip increases. This contributes to reducing the temperature of the crystals during operation.

On the graph you can clearly see the chip efficiency and heat loss as a non-linear relationship. To reduce this you should find one or two resistors on the board. The board is included in parallel with a resistance of a few ohms. This is the sensor to work with. It is in all driver circuits, both linear and pulsed.

The resistor is replaced with another one with more resistance. Alternatively, you can unsolder one of them. The current through the diodes will decrease in proportion to the increase of the current sensor resistance. Even if the current reduction is insignificant, it will affect the service life of the product by reducing the temperature of the crystal during operation.

If an expensive lamp is used for remodeling, there are more LEDs than cheap analogs, and the mode of operation is more gentle. It is recommended to lower the power by about 20-30% only if a new bulb is used. If the chips are powerful, the current through them should be reduced by 50%. If one of the diodes burns out, after some time the rest will also fail. This can happen until all the elements are replaced with new ones.

Gradual increase in brightness after switching on

The next step in refining the LED lamp for 220 V is to ensure that the brightness increases smoothly. To do this you will need a posistor. This thermistor with a positive temperature dependence. It is included in the circuit in parallel with most or all of the chips without exception.

While the posistor is cold, the resistance reading is minimal. The current passes through some LEDs and heats it up in stages. As it heats up, the resistance increases smoothly, which turns on the other chips in the circuit and the brightness begins to increase as well.

You will need a posistor marked WMZ11a (330-470 ohms). The elements can be easily found on sale or removed from an energy-saving bulb of at least 32 W. Devices with lower wattages have a 1 ohm or more posistor, which is not suitable for remodeling.

Video: How posistors and thermistors work and where they are used.

You can get out of the situation by making a parallel connection of several elements, but this method is unpopular. Light bulbs with such modifications are mainly installed in chandeliers on the ceiling. If the circuit is assembled correctly, the inclusion at full brightness will occur in 25-30 seconds.

How to make a night light

The light bulb can be equipped with a nightlight function. It can be installed in a dark hallway and left on at night. Here you need to modify the driver. First, the resistor installed on the driver board, which is used when discharging the output filter capacitor, is removed.

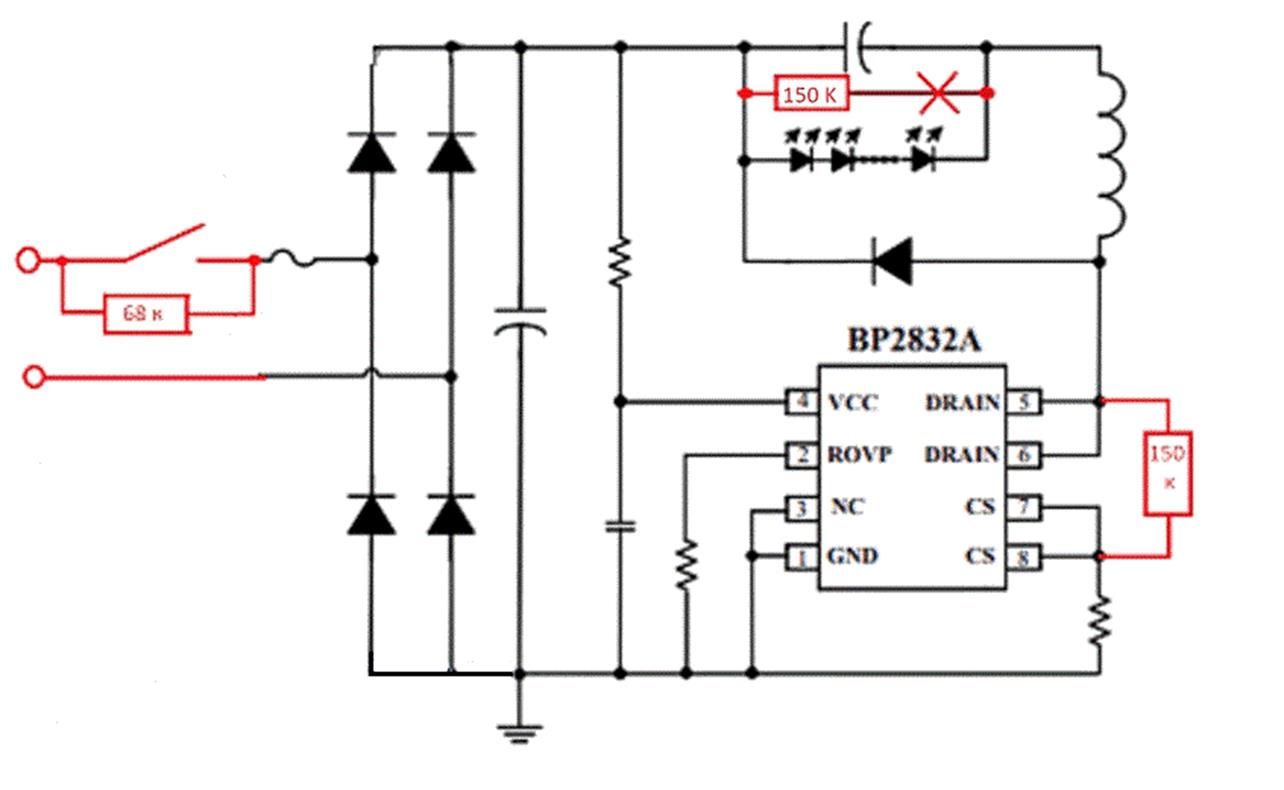

A 1 W 150 kOhm resistor should be soldered into the circuit in parallel to the pins of the microchip. Also a 68 kOhm 1 W resistor should be added in parallel to the pins of the switch.

You can install a 100 kOhm resistor in the driver circuit in parallel to the power supply filter capacitor of the microcircuit. This is to stabilize the voltage and eliminate the blinking of the lamp. If the wizard has done everything correctly, the power consumption will not exceed 0.42W.