Lighting standards for warehouse facilities

Lighting in a Class A warehouse is different from lighting in other classes, so you need to select the indicators depending on the category. It is important to understand all the nuances before designing the lighting and selecting fixtures to avoid any mistakes and help you get it right.

Rules for lighting in warehouses

Regardless of the type of warehouse, lighting must meet a number of criteria. That is why it is arranged taking several factors into account:

- Wherever possible, rooms should be lit with natural light. It can be implemented through windows in the walls or roof, or with special roof structures that are called skylights.

- Artificial lighting is often the main option, the presence of which is mandatory in all warehouses. In this case, the implementation may be different, it all depends on the type of equipment used.

By the way! Luminaires can be powered from the network with a voltage not exceeding 220 V.

Norms of illumination of warehouses - table with basic data.

| Category of warehouse | Illuminance level, lux per square meter |

| А | 300 |

| А+ | 350 |

| В | 100 |

| В+ | 200 |

| С | 75 |

| D | 50 |

Classification of warehouses and lighting requirements

Depending on the class according to the table above selects the lighting of the warehouse - the standards are average, but it is important to understand what premises belong to one category or another:

- "А" - A warehouses and logistics complexes or temporary storage terminals with ceilings from 10 to 13 meters high. The requirements for illumination are high - 300 lux per square meter due to the fact that there are usually a lot of products, and the employees work intensively.

- "А+" - variant with increased requirements for illumination. It is used wherever an improved light of 350 lux is required to provide normal working conditions.

- "В" - This includes all warehouses with a ceiling height of 6 to 10 meters. Most often these are options in industrial and agricultural enterprises and in manufacturing companies of medium and small size, the illumination should not fall below 100 lux.

- "В+" - By analogy with the items described above, this includes premises with higher requirements relating to and standards of illumination, which are twice as high and amount to 200 lux.

- "С" - storage units with a ceiling height of 4 to 6 meters. In fact, this is one of the most common options in businesses, trade organizations, etc. It is not allowed to fall below the norm of 75 lux.

- "D" - Premises with ceilings from 2 to 4 meters, which are used to store goods of any type. Here, the minimum illumination is set at 50 lux.

Choice of luminaires for enclosed warehouses

All goods that need to be protected from the weather and precipitation are stored in enclosed warehouses. To provide quality lighting, there are several guidelines to follow:

- Use the same type of lights to illuminate racks, shelves and aisles. The light should be uniform.When using tall racks, it is important to pay attention to the lighting between them.

- If the height of the ceilings is low, it is allowed to hang low-power equipment on cables or other suspended structures.

- For high rooms, the so-called "bells" are used - Special lamps that distribute light over a large area. The power should be selected according to the height of the location and the characteristics of the lamps.

- The number and location of lamps should be selected according to the size of the warehouse and the nature of the work to be performed.

In areas where lights only need to be switched on occasionally, it makes sense to use systems with motion sensors.

Selecting lighting fixtures for an outdoor warehouse

Open warehouses are used for products and bulk materials that are not afraid of the weather. This option can be either as a pad or with shelving or sheds. The features are as follows:

- Most often the lights are installed on special masts. Their location is chosen so that when loading or unloading, no shadow is formed on the work site.

- The edges of canopies on nearby buildings and sheds can be used as a mounting location.If there are canopies in an open warehouse, lights can be attached to them.

- If shelving or stacks are used in the warehouse, lighting should be moved 5-6 meters higher. To avoid shadows from the structures, lights are placed along the perimeter, as well as in each aisle.

- When working overhead or gantry cranes at loading and unloading sites, the minimum level of lighting must not be less than 50 lux.

By the way! Since outdoor structures are well lit by natural light, light sensors can be installed so that lights turn on when visibility deteriorates below a certain limit.

Naturally, when choosing equipment, you should only choose lights designed for outdoor installation.

Features of installation of lighting systems in warehouses

All regulations are collected in the PUE and SNIP, in accordance with them, when carrying out work on the equipment of lighting warehouses need to comply with several requirements:

- Before the beginning of installation, a project is made and agreed upon. It specifies the location of all fixtures and their power, as well as marking switches, connection points, input power cable and other important information.

- The system must have short-circuit protection. It is selected for a particular warehouse in accordance with safety standards and the characteristics of the luminaires.

- Only options that are resistant to damage and can withstand loads at least 50% higher than planned should be used. Particular attention should be paid to junction boxes and connection points.Attention should be paid to the safety of the system during installation.

- Lay the lighting line separately from other current-conducting lines. An emergency shutdown system should be provided to comply with safety standards.

When installing lights in the open warehouse must be placed so that they do not interfere with the work of cranes and do not create a hazard to cargo transport.

How to arrange for emergency lighting in a warehouse

There are requirements in the regulations for emergency lighting. Its main purpose is to ensure the safety of personnel. Depending on its type, it is classified into two main varieties:

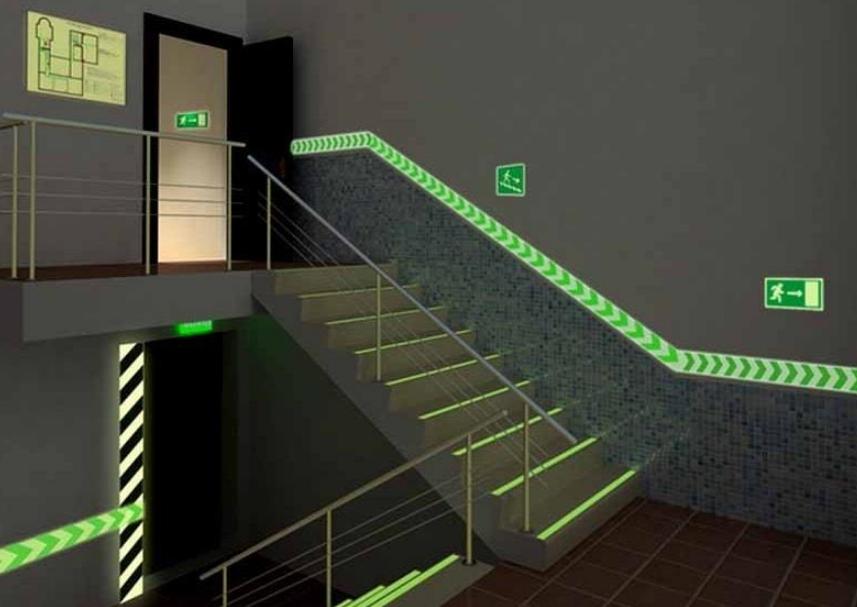

- Evacuation lighting is necessary for the safe evacuation of all employees who are in the territory of the warehouse, in case of power failure on the main lights. It is necessarily a separate line, operating either from an autonomous power source or from a backup system. Norms of illumination - not less than 0.5 lux inside and not less than 0.2 lux outside.Modern emergency lighting provides good visibility and clearly oriented to the direction of evacuation.

- Safety lighting usually starts after the main system is turned off and should be about 5% of the standard brightness levels. Minimum standards are 2 lux inside warehouses and 1 lux outside. It is necessary to be able to complete work and safely leave the room in case of power outages.Battery-powered emergency lighting.

Luminaires with built-in batteries are often used for emergency lighting; they must ensure operation of the equipment for at least one hour after shutdown.

Is Duty Lighting Allowed in Warehouses

Standby lighting has been prohibited in warehouses for safety reasons for several years now. In the absence of people is impossible to guarantee the normal operation of the lights with a voltage of 220 V, there is always the possibility of an emergency situation.

But with the advent of LED lighting fixtures operating from low voltage, it became possible to use and duty lighting, if necessary. It can serve as security lighting, and as an emergency light during power outages.

Not to be forgotten is also an option such as security lightingThe installation can be located along the perimeter of the area or around the building to ensure good visibility and prevent intruders from entering.

To conclude the video: Example of electrical installation work in a tire warehouse.

Organize lighting in the warehouse is not difficult if you comply with the requirements of regulations in the selection of artificial light sources. It is important to select equipment in accordance with the category of the room and the peculiarities of the work carried out.