Rules of installation of lampposts and metal poles for lighting

Installation of metal lighting towers is different from work on the installation of poles made of other materials. Therefore, it is necessary to understand the basic ways to comply with all the conditions prescribed in the regulations. The work is carried out in strict accordance with the established norms, deviations are not allowed.

Installation of outdoor lighting poles - rules and features

Since this type of work refers to the dangerous, requires compliance with safety regulations and a number of requirements prescribed in SNiP 3.05.06-85 and the Rules for Electrical Installation (PUE). All organizations involved in the installation or dismantling of poles must comply with a number of requirements:

- All equipment must be serviceable and inspected. There is an approved procedure that prescribes a period of inspection for truck lifts, cranes and other special equipment. Therefore, only equipment that is approved for use may be used.Only special equipment with the appropriate approvals is to be used for installation.

- By order, the person responsible for safety compliance must be appointed. Each site has a specialist who supervises the progress of the work and is responsible for the result. He supervises the process, the employees and coordinates all work.

- Only persons may be allowed to work, only those who have been properly trained and have the required approvalsif they are required. Minors and those without the required training must not be involved in the installation.

- Employees must receive daily safety briefings. Other safety briefing logs are also kept and filled out on time.

- It is usually required to pass a medical board to determine fitness to perform installation work. If the certificate has expired, the person can not work.

Important! If the lantern is installed in the yard or in the country house, it is possible to carry out the work on their own, provided that the requirements of electrical safety are observed. To put the equipment into operation, most often you have to invite a specialist from a supervisory organization.

How the work is done

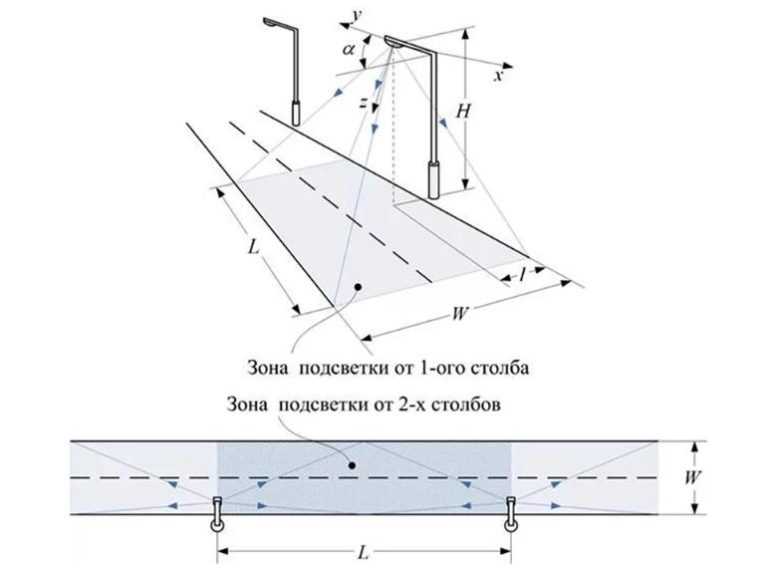

Installation of lighting poles can be carried out in two ways, depending on the type of supports and the chosen technology. The methods are suitable for both steel and composite poles, which are put up in a similar way.

Procedure for the installation of flange lighting supports

Before you start the work, you need to prepare the place for their implementation, should not create any obstacles to prevent danger to others. If there are paving stones on the surface, it must be carefully removed, asphalt coatings are cut through and removed. As for the technology, it is this:

- First of all, it is necessary to dig a hole with a depth of at least one meter, most often it is made deeper. The work can be performed both manually and technically, it all depends on the number of posts to be installed. The shape of the pit can be both square and round, there are no hard restrictions.

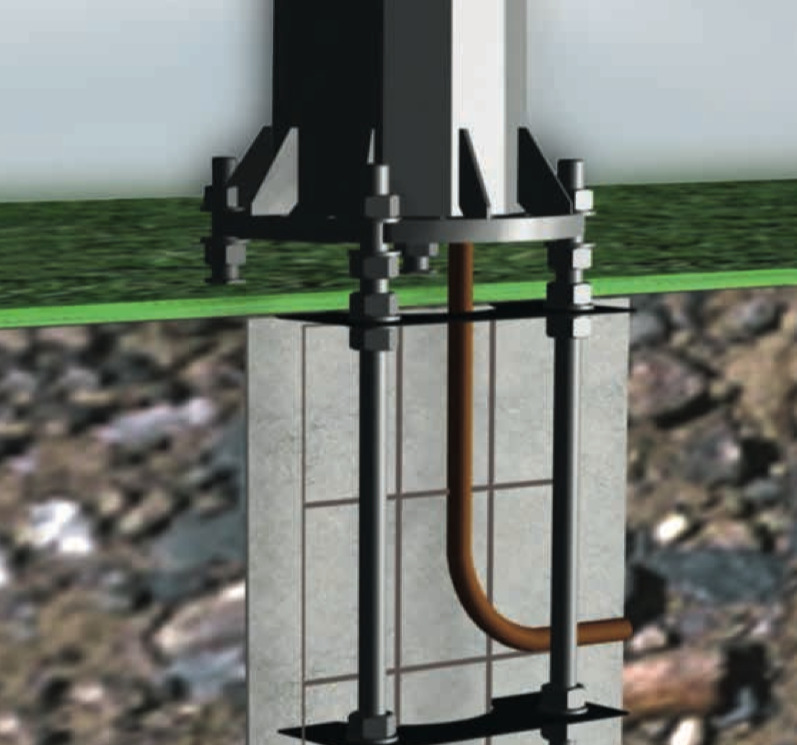

- The bottom of the hole is levelled, a cushion of sand and gravel is made on it, which should be leveled and well tamped. Then a special monolithic reinforced concrete block is placed on which there are anchor studs with ready threads for further attachment of supports. At this stage, it is necessary to align the block correctly so that it is at the required level and is level with the vertical and horizontal planes.The capping flange for the supports.

- If there is no ready-made module, make a homemade one from the armature. A frame is welded to the size of the pit, in the upper part of which bolts or studs are fixed, on which the post will be screwed. It is important to align it correctly, the position is easiest to adjust by backing gravel cushion at the bottom of the pit.

- Then the entire space is filled with concrete of a suitable grade, it is always prescribed in the project documentation. It is important to do it in one go to get a monolithic element with the maximum possible strength. If there are sub-zero temperatures outside, use a solution with special additives.Before pouring the structure with concrete, it is necessary to take out the cables of electricity.

- Concrete must gain strength before continuing the work, it usually takes 5 days. Then conduct the installation of flange lighting supports, aligning the mounting pad with the previously installed studs. Special cotter pin nuts are used for mounting, which can be secured after the connection is tightened.The level when installing the outdoor lighting supports with a flange is controlled using laser equipment.

The option is good because if the pole is damaged or needs to be replaced, it can be done in a matter of hours by removing the old element and installing a new one in its place.

This technology is much more complex and is used for heavy items of large size. The work requires a special drilling rig, or it is done using a crane. The work is done as follows:

- The location of all the posts is determined and marks or other landmarks are made in the right places. The work is carried out with a drilling machine that is positioned exactly on the mark. Usually the minimum depth of drilling is 120 cm, but the hole can be much deeper if necessary to ensure reliability. The diameter of the drilling is always larger than the diameter of the bottom of the post.Special equipment for drilling.

- After the drilling is finished, it is necessary to install the post, for this purpose any suitable equipment is used. The work is done by several installers, as it is necessary to expose the post perfectly even in all planes. After installation, the element is fixed in position with pieces of rebar of suitable thickness and a welding machine. It is important to ensure a stable position, because for some time the post will stand only on the reinforcing supports.When installing upright supports, they are fixed in position with welding equipment.

- All the voids around the post below ground level are filled with concrete mortar. To fill the space and to prevent the formation of air bubbles, the concrete is rammed with a special vibrating machine, the nozzle of which is lowered to the bottom of the pit. The better the concrete is tamped, the higher the reliability of installation.

- Installation of lamp posts completes after hardening of concrete and set them to their original strength, it happens after 5 days. Previously welded supports are dismantled, after which further work on the connection of the system and the commissioning.

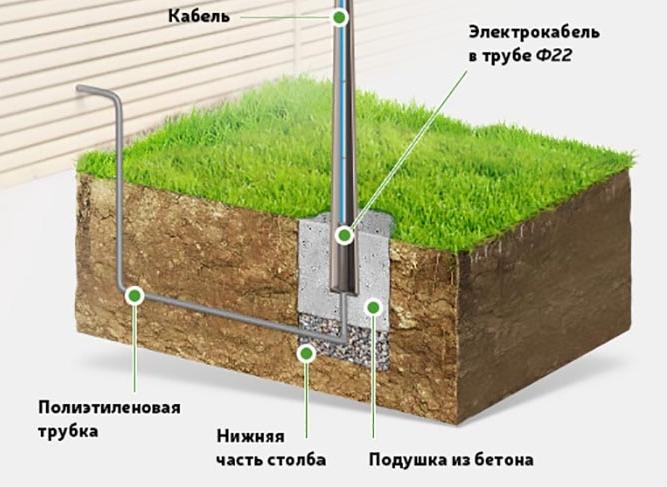

- The wiring can be laid in two ways. The easiest way is to run the cable through the air, securing it to poles and connecting it to each light. But you can also use the underground method of connection, in which the cable is laid in a prepared trench at a depth of 120 cm, using a pipe made of plastic or asbestos. In this case, the cable is led to the base of each pole and led upwards through a cavity inside.Example variant of laying the cable in the ground.

Most often, when installing new supports, it is necessary to dismantle the old ones, so that they do not interfere.

Mandatory requirements for the work

Installation technology must be carried out strictly according to the regulations, and there are also a number of other requirements on which the work should be carried out. Any violations can lead to fines or even a ban on the work, so you need to comply with a few recommendations:

- The necessary design documentation is prepared in advance, this is usually done by individual organizations or the design department, if there is one in the company. After the project is prepared, it must be approved by the organization that supervises the installation work.

- If you want to get permission to work, you need to do all the paperwork in advance. Especially when installation is performed near the road and you need to occupy the roadway or block walkways.

- Often you need the presence of a specialist from the supervisory authority, in this case you can not start without him. If the work reveals problems in the form of loose soil or other deviations, it is necessary to change the technology to ensure the reliability of installation.

After the work is completed, the object must be commissioned. The design documentation, papers on the used poles and components are checked, as well as a visual inspection of the installed elements.

At the end of the thematic video.

To deal with the installation of metal poles is not difficult, if you determine in advance the type of products and clarify the peculiarities of the object. Before you begin, it is necessary to make a project and coordinate it with the supervisory authority.