How solar panels work

The device of the solar panel and the principle of its operation depends on what materials and by what technology it is made. Therefore, it is necessary to understand the features of the main options in order to understand what their differences are and choose the appropriate solution for use. All data are relevant for quality products, cheap batteries may not meet the stated parameters, as they are often made with violations of technology.

Terminology

The main terms used in this field:

- Solar energy - electricity that is obtained from the sun when panels are used.

- Solar insolation - shows how much sunlight is received per square meter of surface perpendicular to the rays.

- Photovoltaic cells - modules capable of converting sunlight into electrical energy. Usually produce 1 to 2 watts of energy, but there are more productive options.

- Photovoltaic system - a set of equipment that converts light from the sun into electricity.

- Solar cells or panels are a group of photovoltaic cells grouped together in a large module and connected in series or series-parallel fashion. Typically, a single battery contains 36 to 40 segments.

- Array - several solar panels connected to obtain the required amount of current.

- Framed modules - structures in an aluminum frame, durable and airtight.

- Frameless elements - flexible versions, they are used in conditions of lower loads.

- Kilowatt-hour (kW) - a standard measure of electrical power.

- Efficiency (efficiency) - solar panels. Indicates how much solar energy that hits the surface is converted into electricity. Typically, the indicator is 15-24%.

- Degradation - reduction of solar cell capacity occurring due to natural causes. Measured as a percentage of the original values.

- Peak loads are the times when the greatest amount of electricity is needed.

- Crystalline silicon is the raw material for making solar panels. The most common and durable option today.

- Amorphous silicon - composition applied to the surface by evaporation and covered with a protective composition.

- Semiconductors - substances that can conduct current under certain conditions. This includes most of the new materials used in the manufacture of solar cells.

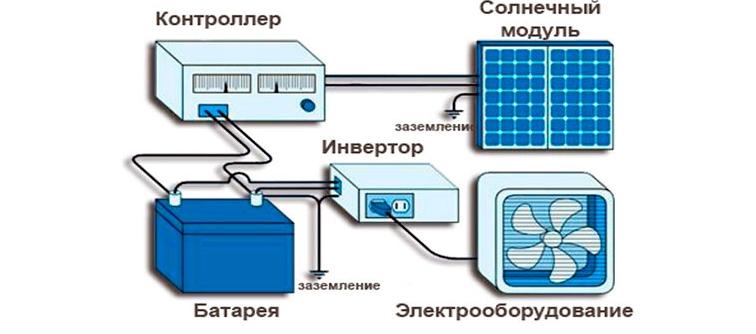

- Inverter - device for converting DC to AC current.

- Controller - regulates the output voltage from the solar modules to properly charge the batteries.

These are only the most common terms, there are additional options. But even knowing the basics will help you understand the subject much better.

Quality categories

To assess the quality of a solar panel, we must first find out the grade of the raw material used to produce the photovoltaic cells. This determines the efficiency and service life of the finished products. There are four main classes:

- Grade A - The best grade, which is free of any damage and cracks. The homogeneity of the filling and the smoothness of the surface guarantee high performance, which is often even higher than stated in the documentation. In addition, this variant has the lowest degradation rate and maintains good performance for a long time.

- Grade B is slightly worse in quality, and may have surface defects. However, it is often used to produce products comparable in performance to Grade A. The degradation index is much worse, so it loses its initial characteristics faster.

- Grade C - option, which can have quite serious defects - from cracks to chips and other damage. In terms of price, such modules are much cheaper, but their efficiency is not more than 15%. Inexpensive solution that is suitable for small loads.

- Grade D - In essence, this is the waste left over after the manufacture of photovoltaic cells, which should not be used to make batteries. But many not very honest manufacturers, especially from Asia, use them in production. The performance of this option is extremely poor.

It is better to choose the first option, in the extreme case the second will do. Only they will be able to provide normal efficiency and will serve for a long time.

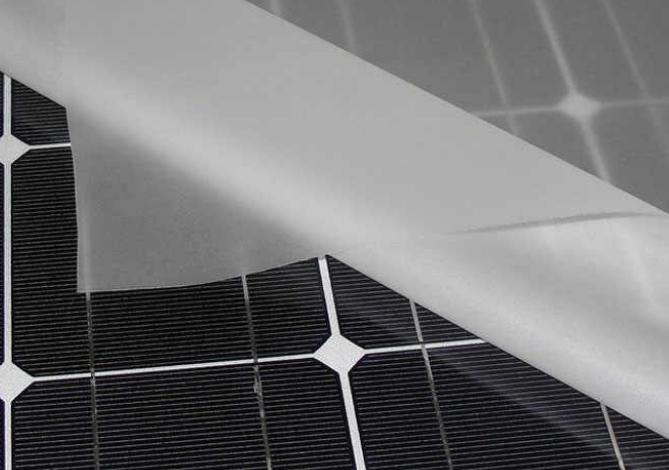

EVA laminating material is a special film that is located on the front side and can be used on the reverse side. The main purpose is to protect the working elements from adverse influences without interfering with sunlight. Quality variants serve for about 25 years, low-quality - from 5 to 10 years. It is impossible to determine the variety by eye, so it is easier to proceed from the price - good-quality options will not be low.

The video shows how the electric current is created by the example of sunlight.

Working Principle

It is quite difficult to explain the features of the solar panel, but it is possible to understand the general points:

- When sunlight hits the photocells, non-equilibrium electron-hole pairs begin to form there.

- Because of the excess of electrons, they begin to move to the lower layer of the semiconductor.

- A voltage is generated in the external circuit. The positive pole appears at the contact of the p-layer, and the negative pole appears at the contact of the n-layer.

- If a battery pack is connected to the photovoltaic cells, a closed circle is created and the constantly moving electrons provide a gradual charge to the battery pack.

- Conventional silicon modules are single-transition cells, which can only generate energy from a certain spectrum of sunlight. It is because of this that the efficiency of the equipment is low.

- To solve the problem, manufacturers have developed cascade versions; they can take energy from different rays of the solar spectrum. This increases the efficiency, but due to the high cost of production the price of such panels is much higher.

- The energy that is not converted into electricity is converted into heat, so solar panels heat up to 55 degrees in the process, and semiconductor panels heat up to 180 degrees. And as it gets hotter, the efficiency of the solar panel decreases.

By the way! Solar panels are most effective on clear winter days, when there is enough light and the low temperature cools the surface.

What are they made of

To study the structure of a solar panel, it is necessary to understand the main varieties, since the production technology has significant differences depending on the raw materials used:

- CdTe batteries. Cadmium telluride is used in the manufacture of film modules. A layer of a few hundred micrometers is enough to obtain an efficiency of about 11% or slightly higher. It is frankly low rate, but in the recalculation per 1 watt of power cost is at least 30% cheaper than traditional options of silicon. Moreover, this variety is much thinner and lighter.

- Type CIGS. The abbreviation means that the composition includes copper, indium, gallium and selenium. We get a semiconductor that is also applied in a small layer, but unlike the first option, the efficiency here is an order of magnitude higher and amounts to 15%.

- GaAs and InP types types are characterized by the ability to apply a thin layer of 5-6 microns, and the efficiency will be about 20%. This is a new word in the technology of producing electricity from sunlight. Due to the high operating temperatures, the batteries can get very hot without losing performance. But due to the fact that rare-earth materials are used in production, the cost of this type is high.

- Quantum dot batteries (QDSC). They use quantum dots as an absorbing material for solar energy conversion instead of traditional bulk materials. Due to the features of the bandgap tuning, it is possible to make multitransition modules that absorb solar energy more efficiently.

- Amorphous silicon is applied by evaporation and has a heterogeneous structure. It is not very efficient, but the homogeneous surface is very good at absorbing even scattered light.

- Polycrystalline variants are made by melting silicon and cooling it under certain conditions to produce unidirectional crystals. One of the most common solutions due to the cheapness of production and good efficiency.

- Monocrystalline Cells consist of single crystals cut into thin plates and alloyed with phosphorus. The longest lasting solution, which has low degradation rates and a service life of at least 30 years, but most often longer by 10-15 years.

By the way! The efficiency of this or that variant depends on the technology of production, so it should be specified.

Pros and cons of solar panels

Each type has its own characteristics, which should be taken into account when choosing, to decide which type is most suitable:

- Monocrystalline panels have the highest efficiencies and save space for module placement. They last at least 25 years and slowly lose power. At the same time the surface is very sensitive to dirt, it should be often cleaned. And the price is the highest of all silicon-based options.

- Polycrystalline variants do not absorb the sun's rays as effectively, but work better in diffused light. In terms of price to quality ratio they are more profitable, but they take up more space due to lower efficiency.

- Amorphous silicon batteries can be placed anywhere, including on the walls of buildings, because they are good at absorbing diffused light. With low efficiency, they have a low price, so they can be used as an economical option. At the same time, they last a long time and are not as afraid of surface contamination.

- Rare earth options have similar advantages and disadvantages, so we can consider them together. They are superior to classic panels in efficiency and can be applied to film, which is convenient. Their temperature range is greater, so heating does not affect performance. But because of the high price and the rarity of metals, such options are not used in mass.

Where to use

All of the considered options can be installed in the private sector to get electricity from the sun and save on energy resources, or even to achieve complete autonomy. In terms of use, there are a few simple guidelines to consider:

- Monocrystalline and polycrystalline options are best placed on the roof or on the ground, having previously constructed a frame at the right angle. It is desirable that the angle of inclination is adjustable, so you can adjust to the sun.

- Film modules can be placed anywhere, both on walls and on roofs. They work well even if the rays do not hit the surface at the right angle, which is very important.

- On an industrial scale, film batteries are also preferred as they are cheaper and easier to install.

There are several varieties of solar panels, but about 90% of the market is occupied by traditional silicon models due to their low price and good performance. You can also choose one of the semiconductor solutions, but then you will have to spend one and a half to two times more money.