4 ways to repair LED strip

LED strips are becoming more popular every year. They fit nicely into the interior of living rooms, entertainment facilities or are used to attract attention on advertising banners. But like any backlight, LEDs can fail after a while. To solve the problem, the strip can be replaced, but this is not always beneficial.

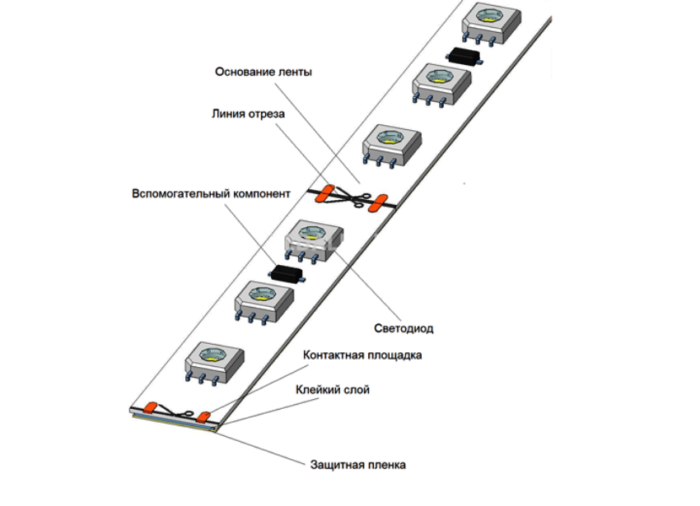

If the breakage is not critical, the elements can be repaired yourself. To do this, you need to understand their design and principle of operation. Experience in soldering microcircuits also comes in handy. But before you start repairing, you need to understand whether it will help or not. Sometimes a breakdown is impossible to fix.

What problems can occur

Causes of breakdowns can be as follows:

- The backlight does not light up completely. First you should check whether the power supply is on. The next step is to check the voltage in the socket. A multimeter or a test lamp is a good way to do this. If everything is OK, it is worth checking the wire that leads to the power supply. If there are no problems, pay attention to the quality of the connection between the ribbon contact pad and the wire. Also, the cause of the problem may be in the circuit board;

- diodes only light up to the center of the ribbon. The cause of the problem is the burnout of one of the segments;

- LEDs constantly flicker. There may be several reasons. One of them is the failure of the power supply unit. It is also recommended to check the connections along the entire length and the supply wires. Sometimes the flicker is due to overheating or gradual failure of the diodes;

- A single piece of tape or some diodes flicker. This occurs because one of the chips is damaged or burned out. It is also possible that the resistor is defective.

The LED strip is not half lit

This failure is common - in one of the segments of the track failed. Diagnosis is to apply power to the sections that are behind the problem area of the LED strip. You should not be in a hurry to blame the diodes for the failure. Sometimes it is caused by a broken conductor. To prevent this from happening, the bends must not be too sharp.

To fix it, the non-functioning section must be removed and the working parts soldered together. This repair option is not always appropriate, as the tape will become shorter. In any case, you will have to buy another product to fill the gap.

Loss of brightness

Loss of brightness may not be noticed immediately. The ribbon will continue to burn, but not as brightly as before. This can happen to an individual segment or along the entire length. Possible causes:

- LEDs are nearing the end of their useful life. If the diodes stop shining as before after 2-3 months, this indicates a manufacturing defect. Fading can also indicate overheating;

- Faulty power supply unit. Check the contacts at the connection between the strip and the power supply. If a plug and socket or connector pair has been used at the junction, oxidation may have occurred, causing current conduction in these areas to be impaired.

No light at all

If all LEDs do not light up, you should look for the cause in the power supply. First, you should check the 12-volt adapter and the availability of 220 volts. The problem can occur on the low-voltage output and input. In most cases the cause is a bad connection on the first three chips section. To find this out, power should be applied from the following diodes in order. If the backlight turns on, the problem area is cut off by a special line.

Blinking

Blinking LEDs can indicate insufficient power of the adapter. To prevent this from happening, each source must have a power reserve of at least 20%. In addition, flickering can be caused by soldering that has been done with aggressive varieties of flux. When joining individual areas, it is recommended to use regular rosin or immediately neutralize the flux that remains on the substrate.

If the product is powered by 220 V, there is a possibility that the smoothing capacitor has failed. In this case, the flicker will be almost imperceptible.

The most innocuous causes of flickering LEDs is a breakdown of the control panel, malfunction on the section of the three chips or the depletion of the resources of diodes.

Diagnosing power supply problems

Check the power supply as follows:

- Check the connector connection to the power supply is secure.

- If the unit has a mains indicator diode, you should check whether it lights up or not.

- If there is no diode, check the functionality with a multimeter. There should be no voltage at the output. Otherwise the unit must be repaired.

One of the first things to check is the remote control. Sometimes you just need to replace the battery. If it has not died, perhaps the infrared sensor has failed.

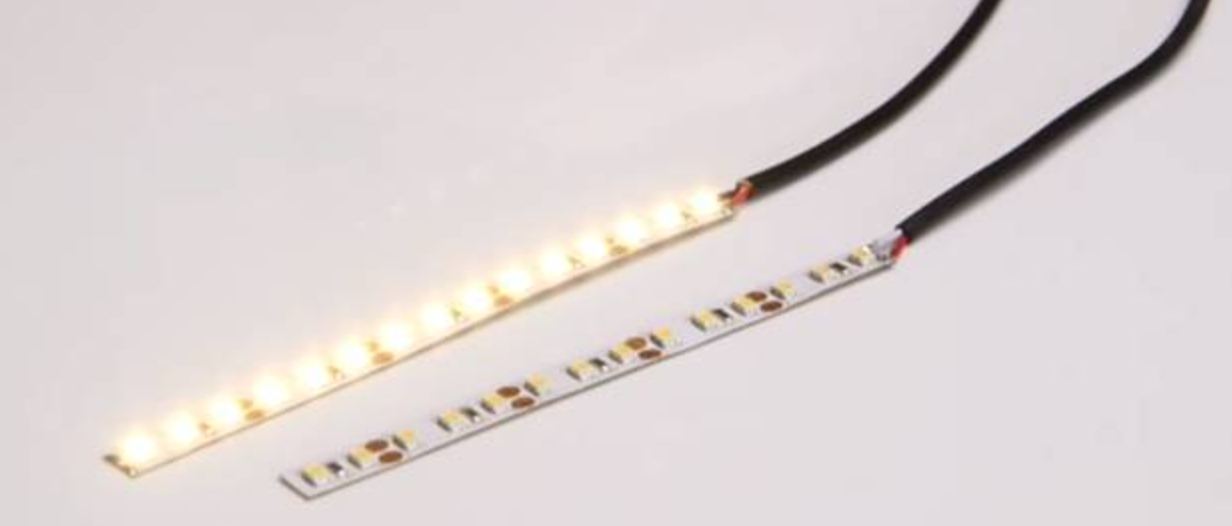

The next step is to check the LED strip. It is necessary to apply voltage to its outputs with two additional wires, without using a power supply. "Plus" is connected to the terminal, it is marked with an arrow on the plug, and the "minus" is alternately fed to the remaining leads. At this stage, the main thing is not to make a mistake, so that there is no short circuit between the wires of the block.

You can supply power from a battery or batteries at 5-15V. The strip will not shine brightly, but it is enough to check its performance. If several chips or one of them is not working, the backlight will not light up only in the problem areas. Repair will consist of replacing the damaged diodes with new ones.

How to fix the LED strip

If one of the chips is burned out, it can be replaced and the backlight can be fully restored. When it comes to the breakage of the PSB plate, repairs will not help. First do a test with a tester, then unsolder the damaged diode, connecting the circuit without it or with another element. In most products, the circuit board is made of aluminum to effectively dissipate heat to the heat sink.

The substrate for heat dissipation on the back of the chip is soldered to the heat sink track. It will have to be unsoldered during disassembly. Plastic printed circuit boards also have such tracks. Based on the material, you need to choose the correct method of soldering. For the work you will need:

- a blade;

- a tester;

- a holder;

- tweezers;

- flux;

- soldering iron (it is recommended that its sting is thin). For a standard soldering iron the sting will have to be made by yourself. A copper wire will do the trick.

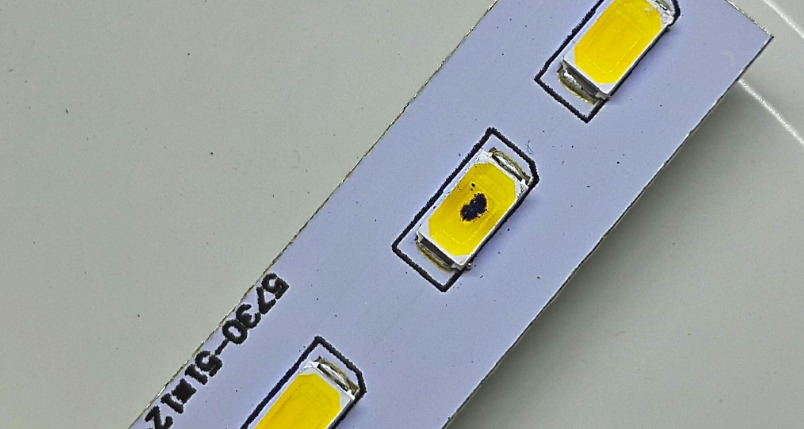

To remove the aluminum board, the case is separated from it. You can use a knife. The board is usually soldered to the base with two wires, they need to be unsoldered. For convenience, the tape can be fixed in a holder. In the next step, use a tester to check each track. A blown diode can be seen with the naked eye, but not always.

It is necessary to inspect the quality of soldering. If the manufacture has allowed a defect, it will affect the life of the diodes. When the burned chip is determined, you need to take a soldering iron and tweezers. The torch should be on the other side of the board. When the solder has softened, the diode is removed with the tweezers. The new chip must be secured before the aluminum base cools down.

Stages of verification of performance

Before buying LED strip all buyers have a justified desire to check its performance. To do this you need to have a battery, such as "crown".

At full brightness the product will not light up. To test a long section, you will need a large battery, such as the one used in an uninterruptible power supply for a computer. It will do as it has 12 volts at the outputs. One of the best options is a car battery. A multimeter or a 3 volt battery is used to test individual LEDs.

Video example of repairing a 220 volt LED strip

Tips before buying a new strip

In search of a suitable backlight, you should not pay attention to cheap Chinese online stores with attractive prices. In such products, low-quality chips are installed, which quickly burn out or dim. In addition, the backlight is unlikely to be returned under warranty.

It is also worth considering the purpose of the LED-tape. It comes in single-color and multicolor. The latter is used as decorative illumination of surfaces or individual objects. Monochrome is suitable to highlight a certain area in the house or apartment, window and door openings.