Main technical characteristics of SMD 5050 diode

SMD 5050 - a model of LEDs, which in a small size is characterized by high brightness. Because of this, they are actively used in the manufacture of LED strips and automobile lamps. On the basis of SMD 5050 were designed such models as 5630 and 5730. Their efficiency index is 80 Lumens per 1 Watt of absorbed power.

The power of 5050 SMD LEDs allows them to be used for the production of home lamps. But more often they are installed in "corn" bulbs. Here are placed from 30 to 100 elements, which provides a good luminous flux. The smallest product gives the same amount of light as a 100 W incandescent bulb.

Description and characteristics of SMD 5050 LED

Before buying SMD 5050 LEDs, you should carefully study the characteristics, because buyers are often sold Chinese fakes that do not meet the stated technical indicators.

LEDs are capable of operating without damage and with the original characteristics of light output more than 3000 hours. When buying Chinese analogues it is worth considering that almost all performance indicators will be about 3 times worse. But it is difficult to recognize fakes without experience.

The following materials are used to create SMD 5050:

- indium;

- aluminum;

- gallium;

- phosphorus.

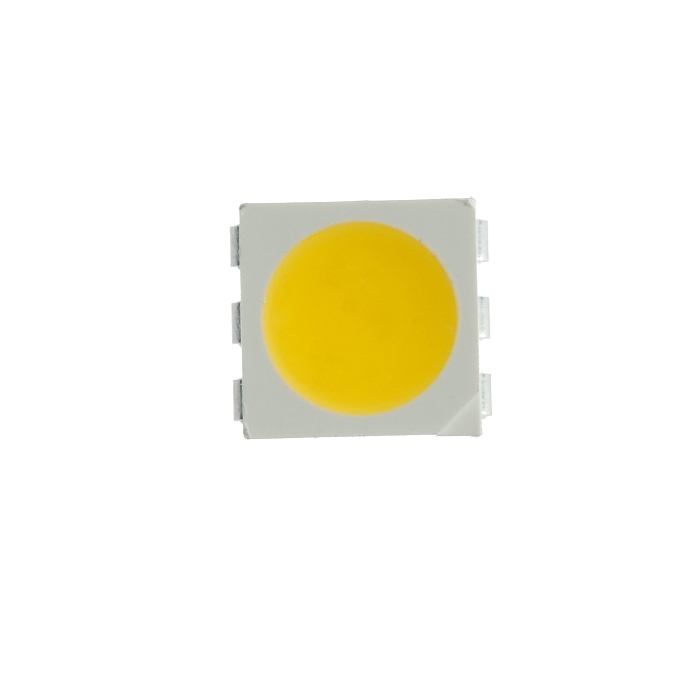

Nitrogen compounds (as alloying agents) are also present. To make the body, the production uses a plastic resistant to high temperatures. The diffuser is a lens poured with epoxy resin. Heat sinks are built in to cool the crystals. Each cell has three cathodes and the same number of anodes.

Features of application

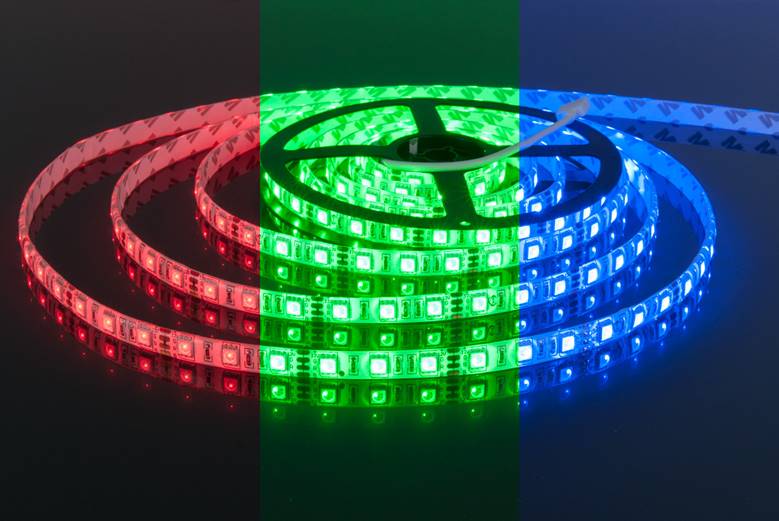

SMD 5050 are unique thanks to the original manufacturing scheme. Produced a long time ago, it is one of the best options for mounting on the tape. 3 separate and controllable crystals allow for different colors of glow, as well as adjustments with the controller.

SMD 5050 is used as decorative lighting for:

- New Year's Eve decorations;

- room decorations;

- Creating light and musical effects;

- Advertising and attracting the attention of potential customers.

To obtain a bright white color with the model 5050 is recommended to connect the powerful elements SMD 5730.

How to choose

To make the right choice, you need to consider the following:

- The presence of a QR code or bar code on the package;

- the presence of characteristics;

- The package must contain a passport and instructions for use;

- The correctness of spelling of the name;

- The package must not be damaged.

The seller should not refuse to return if the diodes prove to be non-functional or do not fit the buyer. In addition, the product comes with a warranty of 1 year if it is the original.

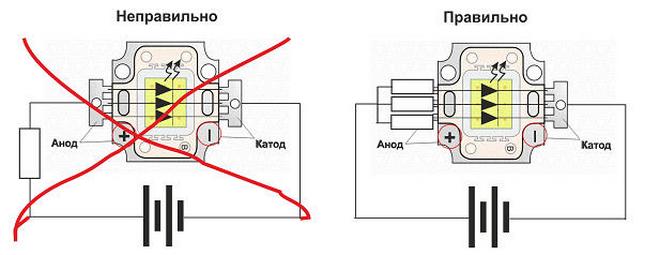

How to connect correctly

Before you buy SMD 5050 LEDs, you should understand how to connect them correctly. First of all, you should take into account the load characteristics of diodes. You can connect to the network only with a resistor. It must be remembered that the resistance of the resistors should not be less than the nominal. This determines the quality operation of each of the elements and the service life.

Wiring diagram

To understand the wiring diagram and be able to work on it, you need to have the skills of an electrician. If a person is working with LEDs for the first time, the probability of performing the correct connection of the elements is very small.

If you have to do the connection yourself, you should study the instructions as best as possible and practice on other LEDs. Here, a common current-limiter-LED connection is used. This scheme is suitable for all monocrystal designs, the only difference is the current limiting element ratings.

An exception is possible in the case of three crystals mounted on the LED matrix. In the 5050 series it has three cathodes and anodes each. Wiring is done for each of them separately.

LED mounting instructions

In production, group soldering is used for mounting. Using a special mechanism, the LEDs are mounted on the board, which is covered with paste. The next step is sending it to the furnace. Here, the paste under the influence of high temperature breaks down into 2 elements: flux and solder. After performing their functions, the flux will evaporate, and the solder will remain on the tracks of the board and contacts, ensuring a quality connection of the elements to the substrate.

To install LEDs with your own hands, a soldering iron is used. Here you should consider the following rules:

- The temperature of the tip should not exceed 300°;

- determine the polarity before starting work;

- contact time - no more than 9 seconds, otherwise the crystal may overheat, which will negatively affect the characteristics or provoke burnout;

- at the time of soldering the body temperature must not exceed 260°.

If you do not have a soldering iron or the skills to work with it, you can You can use a special construction hair dryer. This technology is used in production with solder paste.

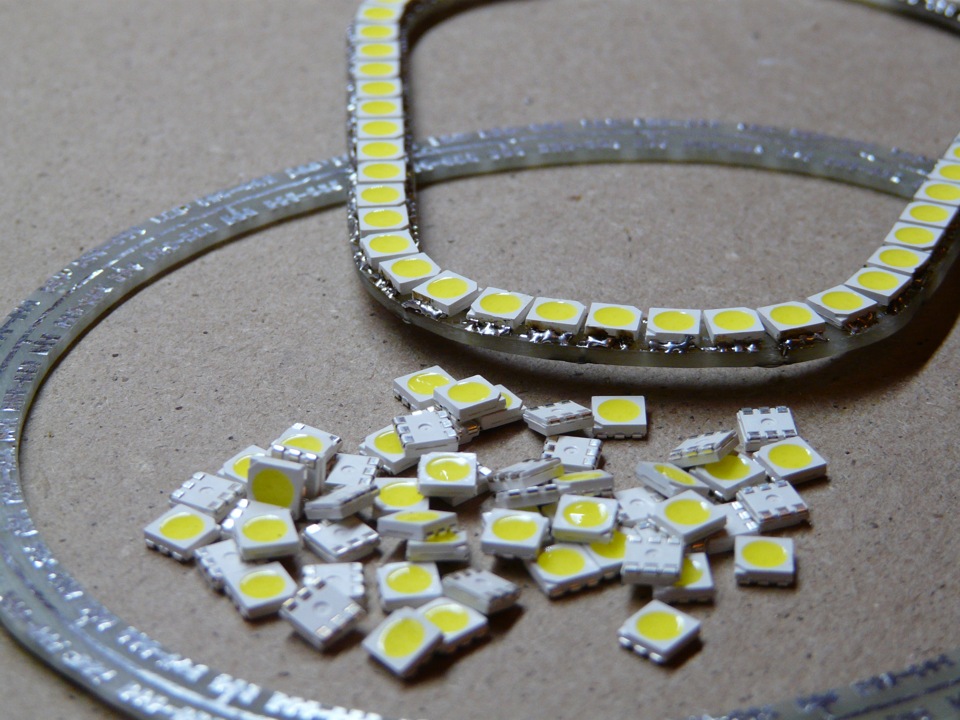

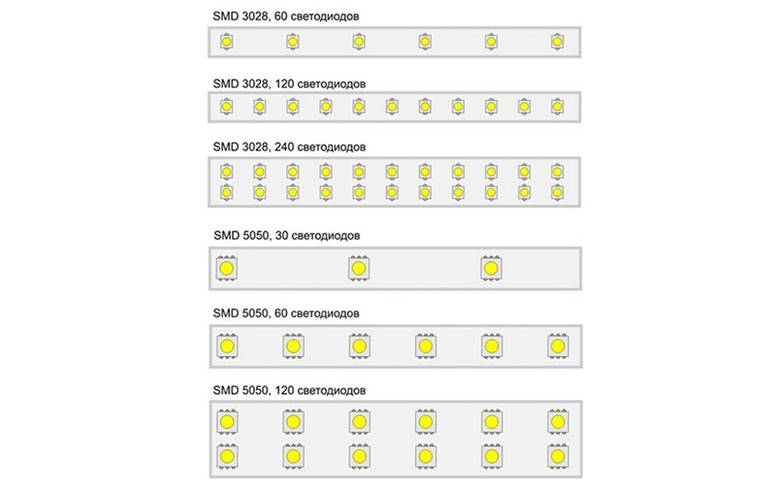

Spacing between LEDs

Density is a technical parameter that determines the number of elements installed per 1 meter of tape. They can be from 30 to 240 pieces. The density determines the characteristics of luminous flux and energy required for operation.

To avoid degradation of the elements, the tape capacity of 120 or 240 diodes per 1 meter should be installed on an aluminum profile. If it is a question of buying the tape on a reel, the manufacturer can specify the total number of elements. For example, 300 LEDs per 5 meters. This means that the density is standard: 60 pieces per 1 meter.

How not to make mistakes when connecting

If there is no resistor, the LEDs should not be connected to the power supply. If 1 resistor is used, you can only make a series connection of elements of the same type. When a diode on three crystals is used, the connection of each is made through a separate resistor and connected to a similar diode in the next module.

Advice to watch video: Mistakes when connecting LEDs.

It is forbidden to connect elements that have different load characteristics. For example, connecting LEDs 5050 and 3528 with each other is not allowed. If a resistor with unsuitable characteristics is used, it will provoke an increase in the load current on the LED, which will have a negative effect on its service life.