Detailed Description SMD LED 2835

SMD2835 LED is a highly efficient semiconductor emitter of artificial light. It belongs to the group of super-bright. While normal brightness LEDs are used for decorative or auxiliary lighting, super-bright LEDs are used as the main light.

LEDs with 40-80W power provide a luminous flux of about 6000 Lm. The light output is 150 to 75 Lm/W, which is 6 to 12 times better than incandescent bulbs.

For example, a 200W incandescent bulb gives a light output of 2500 Lm, i.e. its light output, measured in Lm/W, is 12.5. SMD3528 has 7-8 Lm/W luminous efficacy, and SMD2835 has 20-22 Lm/W, i.e. about 2.7-2.8 times better than SMD3528.

What is the SMD2835 LED?

The SMD2835 LED in the international classification:

- 2835 is the width and length of the LED body, expressed in tenths of a millimeter: 2.8 mm and 3.5 mm. Housing height is 0.8 mm.

- SMD - abbreviation formed from the English Surface Mounted Device - surface mounted device.

- LED is the English abbreviation for Light-emitting diode, light-emitting diode, LED.

SMD2835 LED is a light-emitting semiconductor device. It is based on a p-n junction formed at the interface of two semiconductor metals of p and n conductivity types. In the p-metal, there is bulk "hole" conduction of atoms that have lost an electron and become "holes". There is a movement of conditional positive particles - holes. In n-metal, the carriers are electrons. When electricity is applied, holes and electrons move toward each other.

A moving electron has a high energy potential. Attracted to the hole, it occupies an empty space in the atom, their recombination occurs and a quantum of light is produced, emerging from the end of the p-n junction. The process of luminescence, the output of quanta, will continue as long as electricity is supplied to the junction.

There are several SMD2835 models used in the national economy - 0.09W; 0.2W; 0.5W and 1W.

Appearance and Dimensions

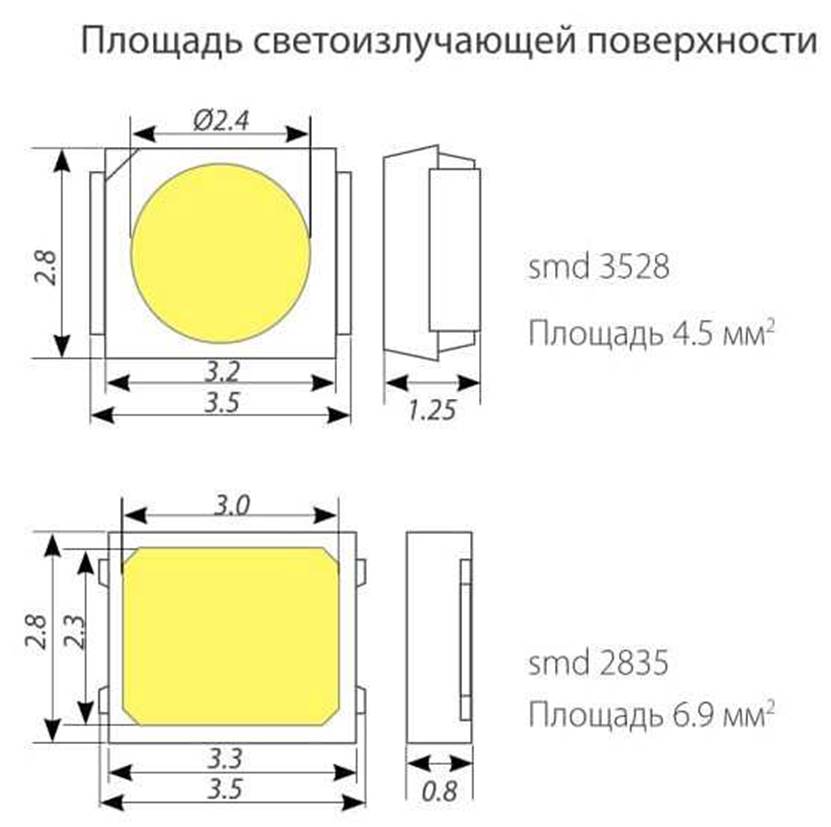

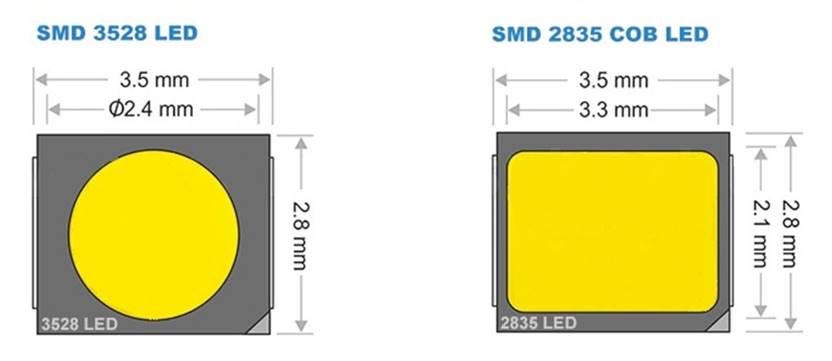

Externally, the bodies of SMD2835 and SMD3528 LEDs are almost the same, they have the same length and width - 3.5 x 2.8 mm.

However, there are external features.

The SMD2835 is more powerful and gives three times the luminous flux and has a yellow phosphor that almost completely covers its outer face. The SMDD3528 has a round spot phosphor and covers a smaller area.

The backside of the cases is also different. SMDZ528 has two narrow contact strips for soldering to the contact pads of the board, the withdrawal and passive dissipation of heat generated in the crystal of the working LED.

The SMD2835 also has two strips on the bottom of the case, but they are wider and take up almost the entire area of the bottom. Therefore, they dissipate much more heat for passive dissipation of the printed circuit board tracks.

Some technical characteristics of SMD3528 and SMD2835 are shown in the table.

| LED model | Size, mm - length, width, height | Light Emission Area, sq. mm | Heat sink | Angle of light scattering, deg. | Light output, Lm/W |

|---|---|---|---|---|---|

| SMD 3528 | 3,5*2,8*1,9 | 4,5 | practically no | 90 | 7-8 |

| SMD 2835 | 2,8*3,5*0,8 | 9.18 | big | 120 | 20-22 |

SMD3528 are available in single- or triple-crystal. The first one is filled with yellow phosphor and gives white light in different shades. The second can have three crystals of the same color or RGB triad. With digital color control, it can give 16 million combinations. The tri-crystal has four contacts - common and one for each crystal.

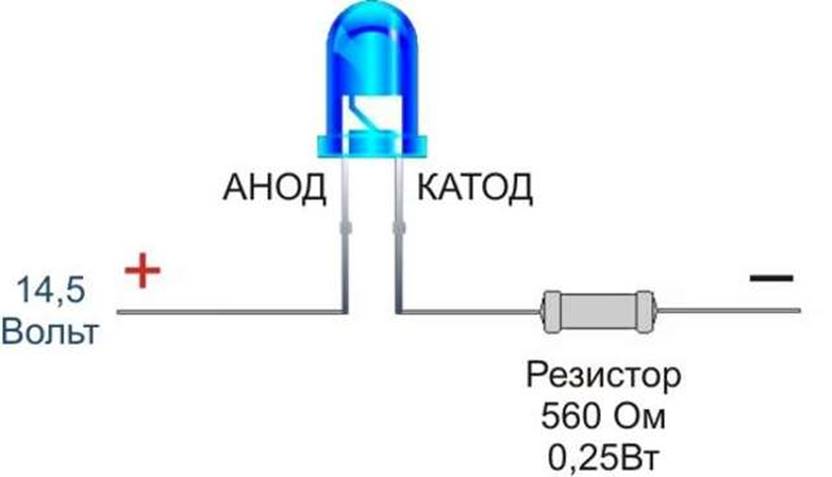

The polarity of SMD2835 and SMD3528 LEDs is determined by the pins of the anode, which is connected to the "+" voltage, and the cathode "-". The anode of the LED in the wiring diagrams is indicated by a triangle, the cathode by a cross line. On the transparent housing cover it is marked with a "key" in the form of a cut corner. On both types of devices, cathode outputs are marked with such keys.

The characteristics of the LED and an entire strip

The characteristics of the SMD2835 super bright LEDs include:

- The housing material is plastic or ceramic.

- Electrical characteristics - operating current, direct voltage, power rating.

- Luminous characteristics (light quality characteristics): luminous flux - brightness or intensity, CRI or Ra - determines the accuracy of shades, color temperature - the shade of white light, expressed in the temperature of a completely black body, measured in degrees Kelvin, the color of the glow - red, yellow, blue, orange, white with multiple shades, etc.

- Climatic characteristics - the operating temperature of the crystal, maximum and minimum air temperatures during operation, humidity.

- The characteristics of the tape include: supply voltage and current, the level of dust and moisture protection (sealing), types of enclosures and LED sizes, placement density, length, color or shade of white light, control possibility - dimmable, control the shade of white light or color of glow, special devices - "running light", side glow.

Parameters by current and voltage

Industry produces several versions of SMD2835 with different power parameters: 0.09 W - 25 mA operating current, 0.2 W - 60 mA, 0.5 W - 0.15 A and 1 W - 0.3 A.

The high electrical and light characteristics are obtained by gradual improvements of the SMD3528 mass-produced LED, one of the first in the group of super-bright, but having traditional dimensions.

The design has undergone the following changes:

- The area of the yellow phosphor, which converts the blue light of the semiconductor light-emitting crystal into white light, was increased, i.e. the circle with a diameter of 2.4 mm and an area of 4.5 sq. mm was converted into a rectangle with an area of 9.18 sq. mm;

- housing height was reduced from 1.95 mm to 0.8 mm;

- increased rated operating current from 20 mA to 60 mA or more;

- expanded the contact area on the bottom of the case for soldering and heat dissipation from 2.32 sq.mm to 2 x 1.8, i.e. up to 3.6 sq.mm.

This increased the light output of the SMD2835 by 2.5-3 times compared to the SMD3528.

Where and how 2835 SMD LED light strip is used

Ribbons of this type have a high brightness of luminescence. That is why they are used as main light sources in residential and work premises, public buildings, shopping and entertainment centers, in decorative, interior and exterior lighting. Sealed devices illuminate elements of the landscape, gazebos, paths, MAFs - small architectural forms and many others. They find widespread use in illuminated advertising - volumetric luminous letters, inscriptions, signs, road signs, fountains, swimming pools, etc.

It can be said that SMD2835 tapes are applicable in all areas of life.

Wiring Diagram

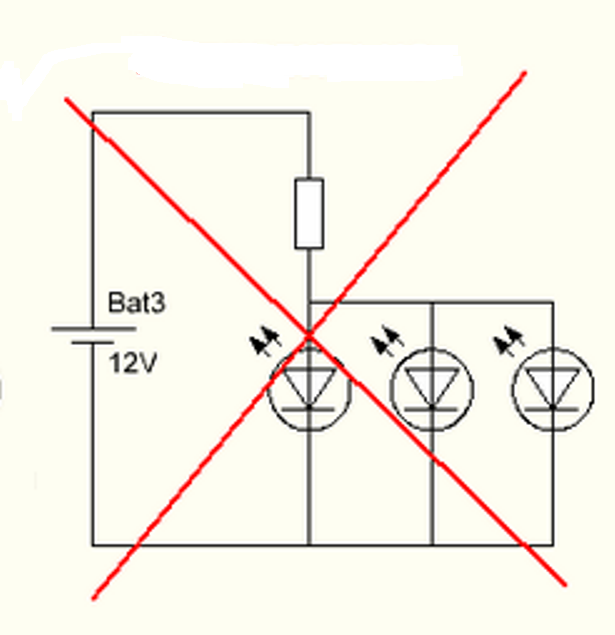

SMD3528 and SMD2835, as well as all other light-emitting semiconductor diodes can not be connected directly to a traditional power supply. The reason is that the internal resistance of the open semiconductor p-n junction is insignificant. Direct inclusion will lead to a large current flowing through the crystal, its rapid heating, which will end in an avalanche-like overheating and thermal breakdown of the p-n junction in the form of conventional combustion. Therefore, it is necessary to limit the current by including a resistor in series with the diode. The disadvantage of this method is useless conversion of "expensive" and high quality power sources into heat, which must be dissipated and dissipated.

Quality power supplies for LEDs converts the mains voltage of 220 V AC 50 Hz to DC voltage. It should have a high level of stabilization and ripple filtering of the mains voltage. In addition, several types of power supply protection are provided.

For medium to high power LEDs this leads to very significant power losses. Therefore, the current through the LEDs is limited in two ways:

- For low power diodes - their series connection of 3 to 6, 9 or even 12 diodes to one DC voltage through a current-limiting resistor;

- for powerful light emitters - using drivers.

When connected in parallel, each diode includes a resistor that dampens excess voltage. In a series connection, the voltage on the chain of diodes is equal to the sum of all the diodes. Excess voltage equal to the difference between the supply voltage and the sum of the voltages on the diodes is damped.

LED, depending on materials, glow color and other factors has a direct operating voltage at the p-n junction from 1.63 V (red) to 3.7 (blue) and 4 (green). In a series connection of diodes, such as in the scheme - LED5-LED8, extra voltage from the power supply "dampen" and dissipate in the form of heat in the resistor R5.

If the diodes are connected in parallel, a common quenching resistor is not allowed. The variation of diode parameters is 50-80%. Diodes will have different voltages due to the variation of operating currents.

Differences of SMD2835 LED strip from 3528

The main difference between SMD2835 and SMD3528 is the brightness. The difference is almost three times in favor of the SMD2835 product.

When the tapes are off, you can see LEDs with yellow phosphor zones on the bodies - rectangular (SMD2835) or round (SMD3528).

Tips: Differences between LED 5050 and 2835 ribbons

Another difference - the SMD2835 tapes only shine white, while the SMD3528 can be red, yellow, green and other colors or RGB with a variable color. They glow statically without changing the luminous flux, or with adjustable brightness and color shade. The brightness can be dimmed manually or electronically.

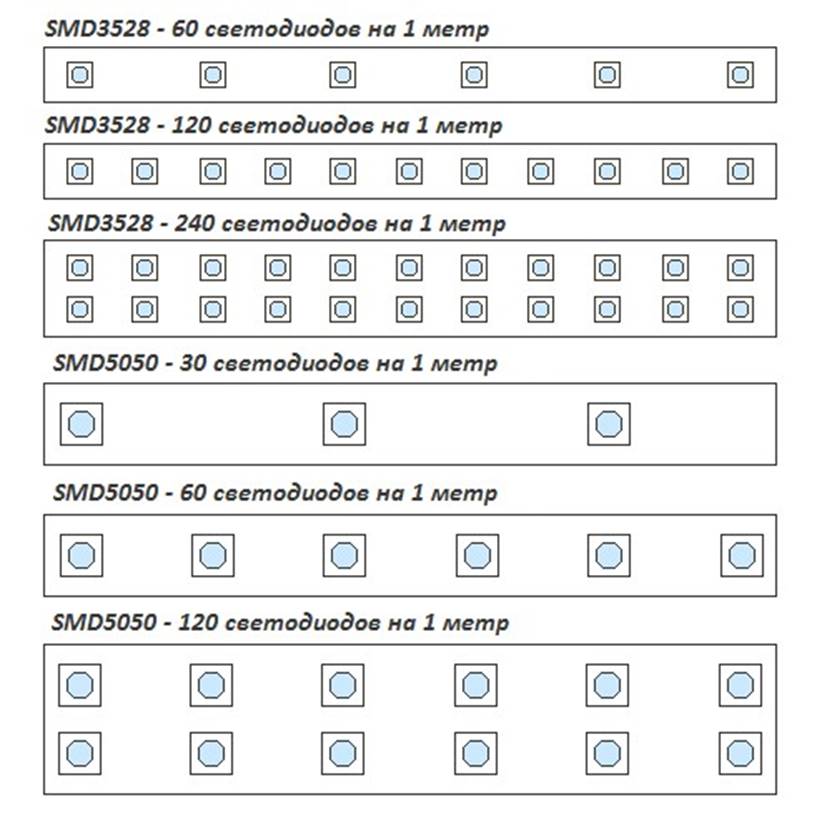

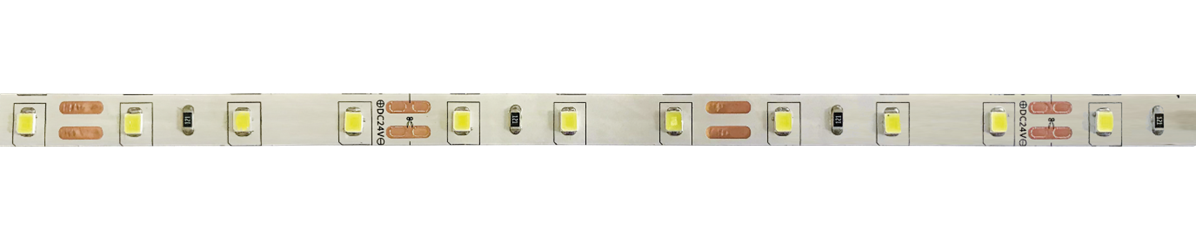

The ribbons are flexible and can be mounted on flat and curved surfaces. To increase the luminous flux, LEDs are placed on a strip with normal or increased density.

Even greater brightness have two-, three-, and four-row ribbons. Such products in operation are very warm. Therefore, special mounting profiles made of aluminum were developed for them.

On the tape yellow elements - LEDs, black - current-limiting resistors, pairs of brown strips - places of cutting the tape into autonomous sections - "pixels". Pairs of contact pads are needed for soldering wires or connecting connectors. Stylized images of scissors are usually placed on these spots.