Types of LEDs that are used in 220 volt lamps

LED devices are becoming more and more popular every year. Diode light sources do not heat up, consume minimum electricity and last over 3-5 years, not as fragile as incandescent bulbs. Let's look at what LEDs for a 220V lamp can be used, how they differ and how they work.

Types of LEDs

Diodes are distinguished by form factor, brightness of luminescence, type of light beam, power, dimensions. But to classify them according to such characteristics is inconvenient, because there can be many modifications. Therefore, LEDs are divided into classes:

- Indicator;

- Lighting.

Indicator are used for color illumination, accentuation and indication. LEDs of this group are characterized by moderate brightness, low power - not more than 0.2 W. They are used for backlighting instrument panels, displays, electrical appliances.

Illuminating LED sources are used to produce LED bulbs that operate from 220 V mains. They are suitable for ceiling and wall lights, car headlights, table lamps and lanterns. Their distinctive feature is an impressive power (up to tens of watts). Powerful light flux allows the use of such products in the lighting of indoor areas, territories.

It is lighting LEDs are put in bulbs for 220 V. They are available in two color temperatures (mostly) - cool and warm white. Complement shock-resistant housing for surface mounting, and also divide into subspecies.

Types of lighting LEDs

The main types include:

- Low-current high brightness SMD LEDs (modules or clusters can be supplemented with a lens to increase the angle of dispersion) - the characteristics of the luminous flux depends on the number of LEDs used in the module;

- COB clusters (linear, round or square design, characterized by a large number of crystals) - are widely used for the production of street lighting devices: lanterns, floodlights;

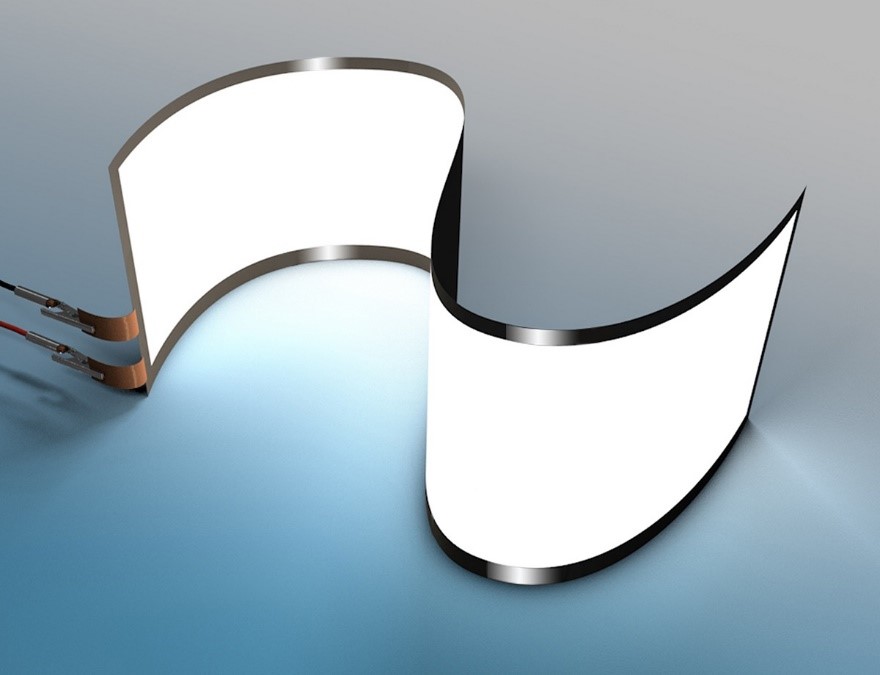

- Filament (rod of a large number of LED crystals, can be up to 20 cm in length) - used to make light bulbs, imitating incandescent lamps, suitable for production facilities;

- OLEDs (have a display type, organic thin-film structure) - innovative light sources, used in designer chandeliers, decorative lamps.

Despite the technological differences between types of LEDs, their functioning is based on a common principle of the emitting crystal - the conversion of electrical energy into a stream of light. Crystals themselves are made from semiconductors with a given conductivity parameters.

Characteristics and peculiarities of assembly methods

When assembling lighting components, several technologies can be used, each of which has its own peculiarities. Let's consider them.

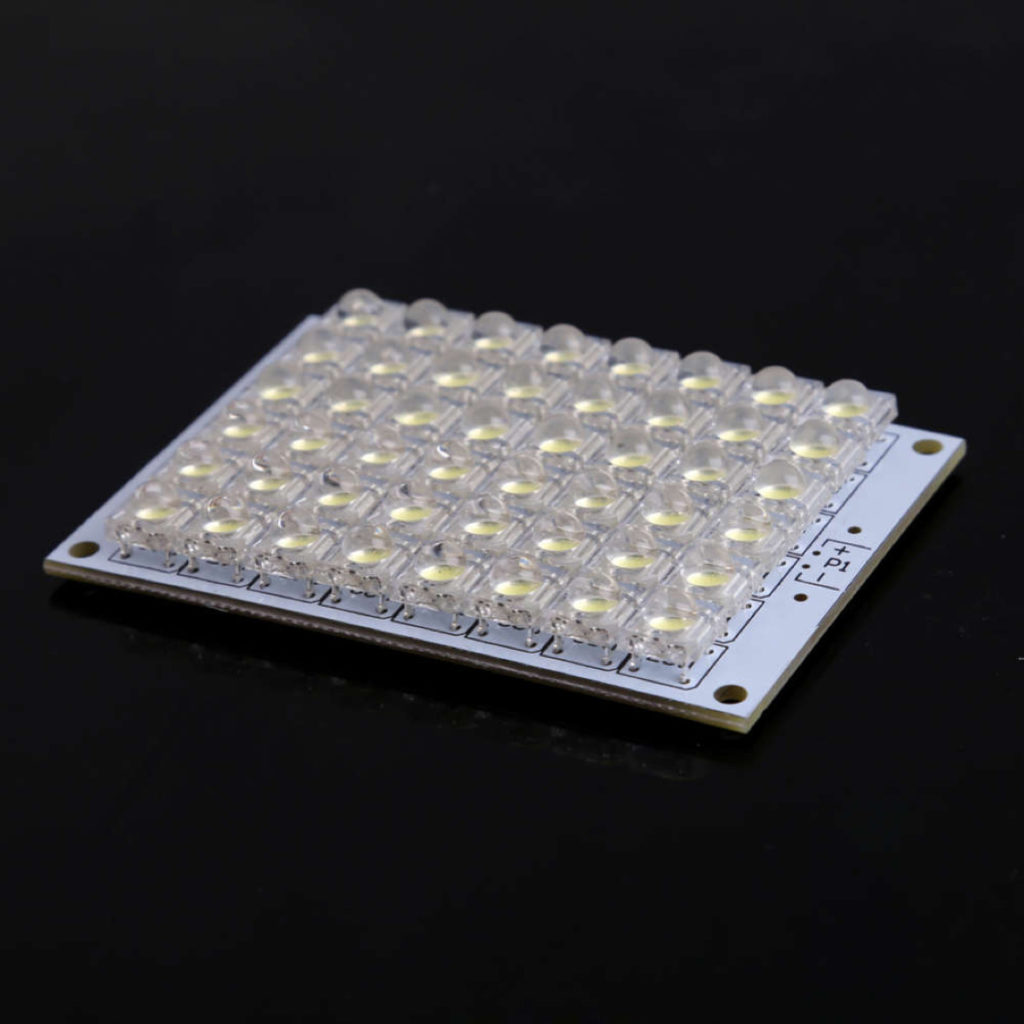

Package type COB

The most advanced type of LED assembly. The element is a plate (board) with a large number of diodes, each of which is placed on a base by surface mounting technology (SMD). One board uses from 20 crystals. To ensure that they glow in the white spectrum, they are coated with a phosphor.

These matrices are not used for backlighting or decoration. They are only suitable for lighting rooms, open spaces. The reason is the angle of light beam scattering of 180 degrees. The use of COB type lighting elements is justified in street lamps, chandeliers or table lamps. The intensity of luminescence depends on the number of crystals.

Features:

- no ceramic substrate;

- No housing, no lens

- Increased power indicators;

- The minimum area of luminescence;

- high density of placement of diodes;

- uniform glow.

When selecting lamps of this type, you need to pay attention to the requirements for lighting the room. Elements with a small number of diodes are not suitable for large spaces.

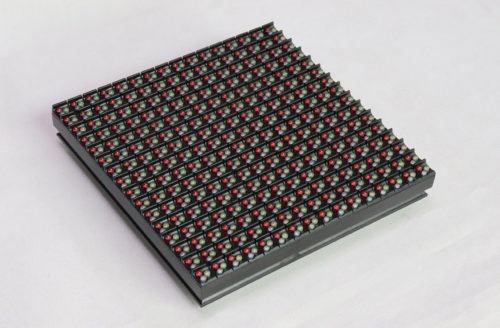

Package Type SMD .

The most common light source assembly technology. Finished lamps have wattages in the range of 0.01 to 0.2 W. The diode is attached to a substrate and can be supplemented with a diffuser lens. One to three LEDs are used on a single substrate. To make a light source with a powerful luminous flux, such SMD elements are combined.

Features:

- have a ceramic base;

- Give directional light emission without a lens - 1000-1300 (with a lens up to 1700);

- Each diode is coated with phosphor separately;

- increased thickness of the element;

- heat sinking substrate is used.

Among the disadvantages - more lamps are required to illuminate large areas evenly. This type of sources is suitable for portable lanterns, sconces, nightlights, table lamps. Such housings are not repairable. If one crystal fails, you will have to replace the entire matrix.

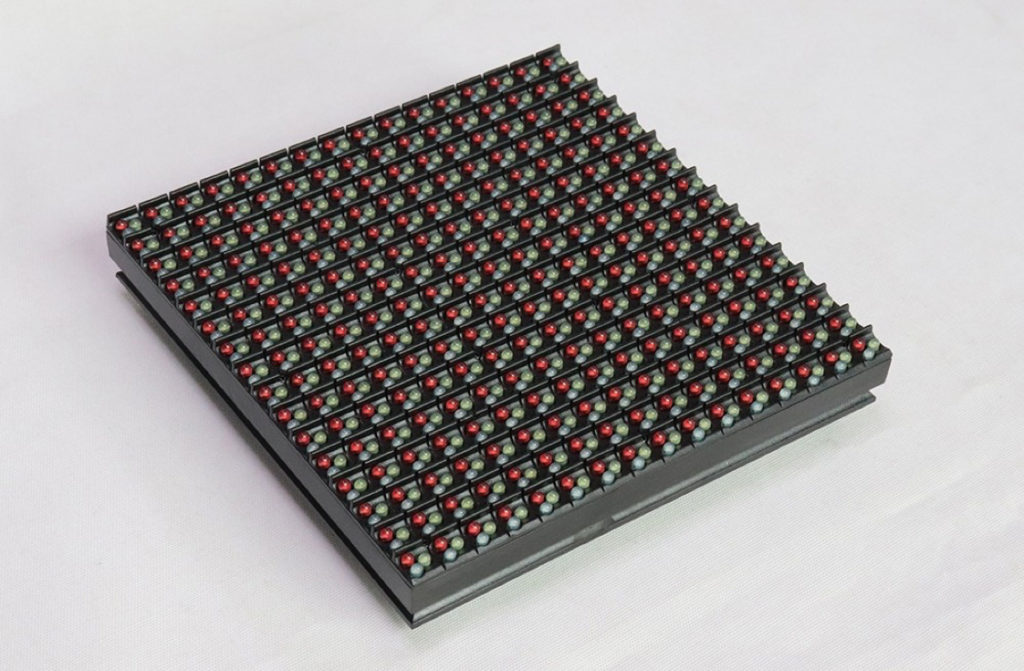

Chassis type DIP

The oldest and seldom used assembly technology today. The design consists of a crystal which is placed on a lead case with two contacts and covered with a scattering bulb (cylindrical or rectangular). Diodes with diameters of 0.3, 0.5, 0.8 and 1 cm are used.

Features:

- weak heating;

- Different colors of bulb;

- Low brightness;

- low power.

Used only as a backlight.

Enclosure type "Piranha".

Analogous to the previous technology, only with 4 pins. The design allows the emitting crystal to be securely attached to the board to ensure a long service life. Available with and without a lens in different colors: green, blue, red and 3 white (glow temperature is different).

Features:

- sufficient intensity of luminescence;

- low heat;

- not bad scattering of the light beam.

We advise to watch video: LEDs "Piranha". Features of application.

Conclusion

Now it is easy to determine what types of diodes are used in LED lamps. These are SMD and COB light sources. The first option is more affordable, sold more often, the second - costs more, less often found on the shelves. When choosing a light bulb you should pay attention to the manufacturer. The market is filled with inexpensive Chinese variants, which often lack a driver, used element base of low quality. The service life of such LED lamps does not exceed 8 months-1.5 years, while quality products are exploited for more than 2-3 years.