Classification of types and systems of artificial lighting

Artificial lighting appeared a long time ago and has undergone many changes. Modern light sources are different from those used 1000, 100 or even 20 years ago. Nowadays, not only the normal performance of work, but also a comfortable stay at home depends on quality light. To ensure optimal conditions, it is necessary to understand the varieties of equipment and its main features.

History of artificial light sources

The first artificial means of lighting was the fire of a fire. In ancient times, people located near the fire in the dark, to ensure normal visibility and to protect themselves from wild animals. But this option had a significant disadvantage - it could not be carried, so over time more mobile solutions began to appear.

Chandeliers, lampstands and candles

Over time, people noticed that some resinous woods burned much better and longer than others. So they began to use them for lighting that could be carried over short distances. Then various natural resins and oils were used to improve the effect. They soaked wood or dry vegetation in them to provide illumination.

The first self-contained version of light was torches, most often wrapped in cloth or fibers soaked in animal fat, oil or oil. Techniques varied from region to region, so the burning time varied, all depending on the quality of the impregnation.

The first lamps were primitive: a small clay vessel was filled with some fat, tar, oil or oil and a wick was placed. This version burned much longer, so it was best suited for lighting dwellings. Over time, the design was refined so that it could be conveniently carried and moved around on the street.

The next stage in the evolution of lighting devices were candles. Wax or paraffin was used for them. This option was superior to all previous ones, but also had a number of disadvantages.

By the way! Features of the development of lighting elements depended on the region and available natural materials.

Gas lanterns

With the development of such sciences as physics and materials science, people discovered the interesting properties of some gases. It turned out that when they burned, they gave bright light, so it was possible to illuminate large spaces. Gas was supplied either from cylinders, replaced as needed, or by pipelines.

Wicks were also improved. Instead of quickly burning hemp wicks, other variants with special impregnations were used. And the system of regulating the flow of gas allowed to save fuel and adjust the brightness.

Electric light sources

After the discovery of electricity, artificial light made a qualitative leap in its development. Scientists selected materials that could emit light when heated to high temperatures. Initially, graphite, tungsten, rhenium, molybdenum, and platinum were used. Because of the heat, filaments and spirals burned out quickly, so they were placed in a glass bulb, from which air was evacuated or filled with an inert gas.

The most common bulbs used in incandescent bulbs were an alloy of tungsten and rhenium. Also widely used are lamps powered by electric arc and glow discharges, which were discovered during the invention of conventional light bulbs.

Types and systems of artificial light

Types of artificial lighting come in many forms, depending on location, direction of flow, and purpose. Each of the classifications has features, so you need to understand them in order to use the option that suits you best.

By location and purpose

There are only three varieties here, and they are versatile and suitable for both industrial and residential environments. Features of each type:

- General lighting is located on the ceiling or walls. The main requirement is an even distribution of light across the room or production hall and ensure normal working or resting conditions. For a small area, a chandelier or lamp in the middle is enough. In other cases, the following must be calculated in advance the number of of the equipment and its positioning is calculated in advance.General lighting should provide uniform light over the entire area of the room.

- Local lighting helps to highlight a particular area or work surface. And this can be achieved by using ceilingIt can be ceiling mounted, wall mounted, floor mounted, recessed or table mounted. In some cases, the best solution is the adjustable models, in which the light flux is directed where it is needed.

- Combined versions combine both types and allow for a better result. In this case, the general lighting works all the time, and the local lighting is switched on when necessary.

You can install a system of lights that turn on in different modes to provide lighting for the desired part of the space.

According to the direction of the luminous flux

On the type of light flow depends on the comfort for vision. In addition, in different conditions it is necessary to use different solutions to ensure the best result. The basic types are as follows:

- Direct Direct light. Light falls directly on a surface or object. This provides good visibility. The main thing is to choose such a variant so that the light does not strike the eyes.

- Indirect lighting. The light is directed to the walls or ceiling and illuminates the room through reflection. Suitable for living space, creates a comfortable environment.Chandeliers with reflected light are good for living space.

- Scattered lighting. Another type that does not create visual discomfort. The light from the bulb passes through a diffusing plafond and is evenly distributed around.

- Mixed lighting. Any combination of the options described, if it provides a good result, can be used.

Functional features

Functional features are important for industrial and working spaces, so this classification is more about them. Several types are distinguished:

- Working. Must provide normal working conditions. Can be both general and local.

- Duty. To be switched on during non-working hours. Serves both for visibility and security purposes.

- Emergency .. Must provide illumination of escape routes in case of power outages. Luminaires usually operate from self-contained power sources.Emergency lighting must ensure the safe movement of people.

- Signal. Provides visibility in high-risk areas.

- Bactericidal. Used in medical and other facilities to disinfect the surrounding air, water, or products.

- Erythema lighting emits ultraviolet waves of a certain frequency. It is used in rooms without natural light and replaces ultraviolet radiation from the sun to stimulate physiological processes in the body.

Special types of lighting may also be used in specific types of production.

Video lesson of the Faculty of MGTU named after N.E. Bauman: course BZhD. Lighting.

Basic parameters of artificial light sources

All requirements established by law are in SNiP 23-05-95. And the latest information collected in SP 52.13330.2011. "Natural and artificial lighting". On the basis of these documents the optimal lighting characteristics are selected. As for the parameters, the following are considered the main ones:

- Operating parameters of the electrical network. Usually the equipment operates from the standard voltage of 220 V, but there may be other options.

- Power of electric lamps in watts. Here it all depends on the type of equipment and the illuminated area.

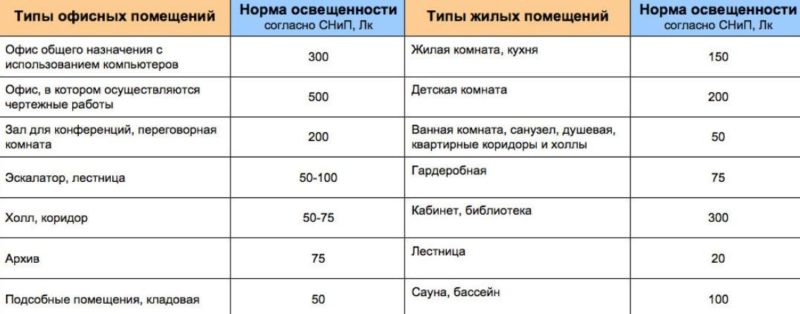

- The norms of illumination in lux. There are tables with precise data for all types of rooms.

- Color temperature. This determines the quality of illumination and visibility in the room or within the workplace.

- Color rendering index (Ra). Indicates how well colors are perceived compared to sunlight. For normal perception the index should be 80 or more.

- The presence of additional devices. This can be a step-down transformer, ballast, or dimmer.

The quality of artificial lighting determines the comfort of staying in the room or the efficiency of work. It is necessary to select equipment that creates optimal conditions and provides minimal strain on the eyesight.