Installation of headlight autocorrector

The article tells in detail about the role and importance of the headlight corrector during driving, familiarizes with different types of these devices, the principles of their operation. Gives an example of how to install automatic headlight corrector with your own hands with detailed instructions.

Principle of operation and purpose of the corrector

The main task of the automobile headlight position controller is to protect the driver from momentary dazzle of oncoming car lights. It concerns the dipped beam mode, when the risk of losing vision for a while is very high.

The spectrum is distributed completely differently in the high beam mode, and here the help of the corrector is essentially unnecessary.

Another option provided by this detail is to normalize the light direction of the headlights of a loaded vehicle. When the trunk of the car is well-filled, the front of the body is slightly lifted, and, accordingly, the light stream from lights is displaced a little bit higher than it should be. It is fraught with a risk to dazzle drivers of passing cars. That's why the corrector makes the beam position remain unchanged when the body is shifted.

Adjustment settings should be set before loading the vehicle, not after.

Types of headlight correctors

The principle of operation and structure of headlight correctors does not differ significantly depending on the type of device. The three main elements in its design are:

- track clearance sensor;

- control mechanism;

- Motor with a reducer.

The only difference - in the way of adjustment. We will talk about the types of regulators further on.

Manual

Headlight correctors of this type, as the name becomes clear, are activated manually. The device uses one of the types of actuators:

- mechanics;

- hydraulics;

- pneumatics;

- electromechanics.

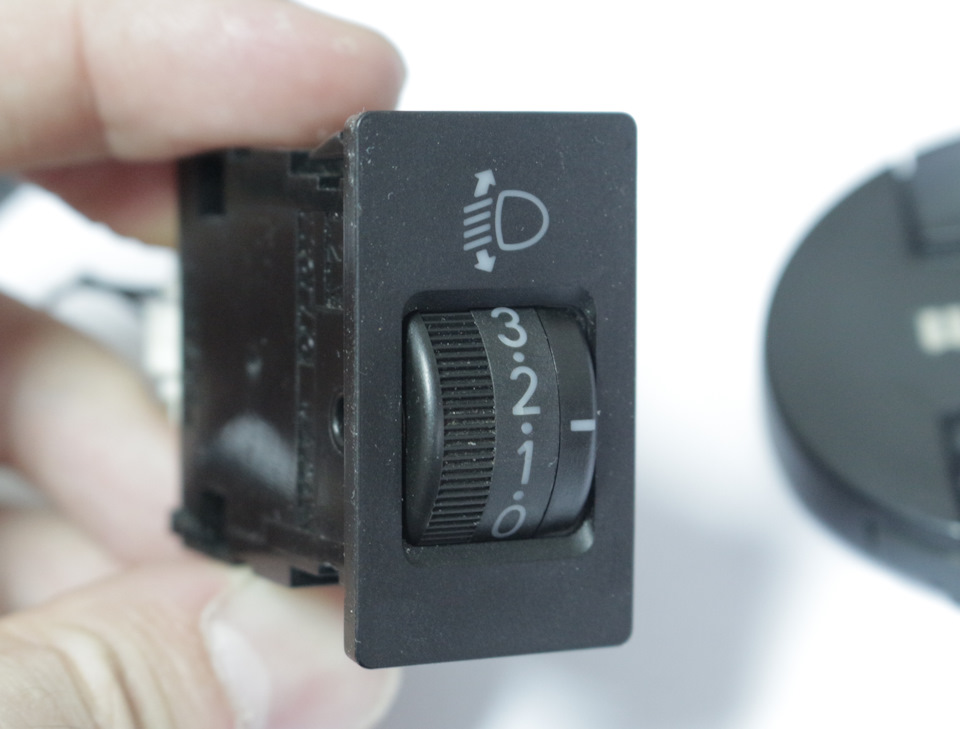

It is activated by turning a small toggle-wheel switch. It has a special scale with a marking of the headlight position - either numerical or graphic. After assessing the change in the center of gravity of his car after loading the trunk, the driver selects and sets the corrected position of the lights with the wheel.

After that, the motor is activated. The reducer, after receiving a command from the wheel, drives a special rod that moves back and forth under the headlight. By touching it, it sets the required angle of the headlight. It's that simple. Actually this simplicity of usage is one of the main advantages of manual correctors along with their cost. The drivers of not expensive or old cars can afford them.

Automatic .

This variant does not require any human intervention at all. The adjustment of the headlight position is carried out automatically. If the sensors record deviations from the normal indicators, the system itself corrects the direction of the light. Automatic correctors are best suited for headlights on halogen or xenon. The latter require the corrector at all.

The main parts of this automated mechanism are the rotor and stator. Several non-contact sensors are mounted on the bottom of the body, which, in turn, are connected to the suspension. Information about the suspension stroke is delivered to the rotor. By turning it, the magnetic field changes. The control system reacts to this, which converts the magnetic field change indicator into the desired headlight rotation angle. As a result, the corrector mechanism sets this angle.

Installation rules for the corrector

Since the automatic headlight corrector is not a luxury, more and more car enthusiasts are mastering the constructing and installation of such devices by their own hands. It is impossible to make a dynamic regulator at home, but an electromechanical one is another matter. Any driver versed in the construction of the car will be able to do it.

What you need for installation

If the light position controller that worked before is out of order, it must be removed from the car: it is a prototype for making or buying a new part.

To install a new electromechanical auto-corrector on the headlights, you will need the following handy tools:

- 5 pieces of stranded wires with a cross section of 0.35 mm squared, length 1.65 m and 2.55 m;

- 20 pieces of electrical terminals type "mom";

- 2 PVC pipes;

- 1 block with 5 pins;

- 2 strips with 11 contacts;

- 2 thick cables for power supply.

In addition, for the conceived case, you have to be "on your toes" with a soldering iron.

Step by step instruction

The installation of the headlight position corrector itself takes place according to the following algorithm:

- Close the tubes near the battery, drain all the liquid from them.

- Dismantle the master cylinder. It is usually unscrewed with a screwdriver in a counterclockwise direction.

- Remove the lever from the headlight control unit in the cabin. For this you can use a spark plug wrench.

- Remove the unit, piping and plug from the vehicle's engine compartment.

- Measure and cut off a suitable length of wires that will connect the corrector unit to the motor gearboxes.

- Securely insulate the wiring.

- On one side of it you need to unsolder the terminals, and then carefully insert them into the connection block.

- The next step is to pull the wiring into the hole in the motor panel.

- In the same way, you should unsolder the terminals at the other end of the wiring, and then place them in the motor drive connection holes. The terminals must be securely insulated before doing this.

- Connect the power supply from the 4 female terminals.

- Connect the mass cable through the terminal that is connected to the ignition relay.

- Install the geared motors in the standard hole, fix them securely by means of gaskets and harnesses.

- Set the corrector sensor to zero position.

Read also: Headlight adjustment with your own hands

After installation, you must immediately check the operation of the new autocorrector. This is done simply: load the trunk, start the car, turn on the headlights. If the light angle remains the same with both loaded and empty trunk, then all works well.

Video instructions on how to install the corrector.

Checking corrector work

You should check as often as possible whether the headlight corrector is working properly. After all, this is one of the guarantees of safe driving in the dark. Each type has its own limited lifetime: automatic - up to 15 years, manual - less. It is possible to understand that the correction system does not work properly or is out of order at all, if the headlight drive does not make a monotonous, slightly buzzing sound when you ignite or turn on the dipped beam. If there is a strong suspicion that the manual mechanism is out of order, it is worth doing the following:

- Disconnect the position sensor lever mount.

- In the dark time of the day put the car with a loaded luggage compartment against a light monochrome wall and turn on the dipped beam.

- Change the lever position and observe if there is a change in the light output.

- If the direction remains the same, then the corrector is out of order.

The most common cause of failure is wiring. It is best, of course, to have regular computer diagnostics of the functioning of the light position adjuster at a car service.