Ultraviolet lantern with your own hands

Not so long ago, the available source of ultraviolet light were fluorescent lamps with the appropriate spectrum. Their linear size, necessity of using ballast, 220 V power supply voltage did not allow building compact, mobile, low-power UV sources. The advent of light-emitting diodes working in the UV area has radically changed the situation, and it is now possible to make a UV flashlight yourself.

The design and scope of the ultraviolet flashlight

The design of the flashlight is not complicated. It contains almost the same elements as the usual:

- the emitting element (LED);

- power supply;

- housing (with or without a reflector in the reflector);

- driver (the lamp with an incandescent lamp does not have one).

The UV emitter has a wide range of applications:

- for detecting counterfeit paper money and documents;

- to search for biological material (animal urine, blood traces, etc.);

- for entertainment purposes - many objects have an unusual color when illuminated by UV light;

- for curing certain adhesives;

- such a flashlight will help with the search for amber on the seashore (you should study the legislation in this area);

- for uncomplicated home defectoscopy (although production uses more powerful emitters).

You can buy the device in a store or on the Internet, but with minimal skill it is absolutely uncomplicated to construct a UV flashlight for personal purposes with your own hands.

How to make a UV flashlight yourself

The easiest way to make a UV flashlight is to take a LED flashlight of visible light and replace the emitting elements with ultraviolet. You can buy them at a radio parts store or online. You should pay attention to two important parameters: the operating voltage and the maximum forward current. For some common types of LEDs these characteristics are shown in the table:

| LED type | BL-L189VC | GNL-3014VC | BL-L522VC | SMD 3528 | SMD 1206 |

| U oper, V | 3,8 | 3,5 | 3,8 | 3,6 | 3,6 |

| I oper, mA | 30 | 20 | 20 | 60 | 20 |

In terms of voltage the element is selected simply - the LEDs must be assembled in a series chain, the operating voltages are summed up and the total value must not exceed the voltage of the power supply. So, with four AA or AAA elements installed, the output value will be 1,5x4=6 V and the maximum number of one and a half volt LEDs will be 4 pcs.

With the current is a little more complicated. It has to be limited to about 90% of the maximum value. There are two ways to do this:

- Installing a driver;

- Installing a quenching resistor.

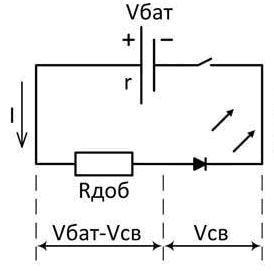

The first way is more suitable for advanced radio amateurs. If you choose the second way, calculate the resistance according to the formula Rdob=(Up-Urab)/(0.9*Ipr).

Important! After assembling it is better to measure the actual current in the LED power supply circuit and choose the resistor rating more accurately.

Next, remove the board from the lamp with the elements already installed and pick up new UV-LEDs by characteristics and size - the closer the dimensions and design, the easier it will be to solder.

The old elements should be unsoldered (or carefully bitten out, if further use is not expected), taking care not to damage the board. In their place install UV emitters, solder the resistor.

If you can not remove the LEDs without damaging the board, it is easy to make a new one. To do this you need a piece of foil textolite (single sided or double sided). It is necessary to cut the board to the shape of the regular board, mark the holes for mounting and make a marking of the number of LEDs planned for installation and their shape. Do not lose sight of the fact that one of the mounting screws is also the minus contact of the power supply, so it is necessary to provide a platform for it. Also don't forget the hole for the wire from the positive terminal of the battery.

The tracks can be cut, or you can draw them with nail polish (nail polish, etc.). Advanced craftsmen can do a LUT or photoresist drawing of the board. It will be neater and prettier, but the amount of work will be unnecessarily high. Then the board must be etched in chlorine iron or a solution consisting of:

- 100 ml of hydrogen peroxide (sold in pharmacies);

- 30 grams of citric acid;

- 2-3 teaspoons of table salt.

Next it is necessary to solder the LEDs (observing polarity) and a resistor in their original places and assemble the flashlight.

Important! When reassembling it is necessary to pay attention to the material from which the "lens" covering the compartment with emitting elements is made. If it is glass, putting it back in place is not recommended - it greatly weakens the UV flux. Plastic "lenses" absorb UV much less.

It may turn out that the required power of the lantern exceeds the ability to install the power cells. If you do not need autonomy (indoor use only), you can arrange for power from a power adapter designed for higher current. To do this, you need to buy a power supply and a mating connector to it. The mating part is mounted on the lantern body in any convenient place. There are many variants of connectors and their design, so the method and point of installation depends on the lantern body and the fantasy of the master.

The key point is that there is only one body with an empty battery compartment left from the original flashlight. It may be uncomfortable and cumbersome, it can be replaced by a homemade casing made from improvised materials, or you can pick up (buy) a ready-made case, and the board with the radiating elements prepare for it. The design of the flashlight will be fully exclusive.

Video: Quickly making a UV flashlight from a regular LED

Simulation of UV-light

Sometimes you do not need a source of UV light, but its imitation - to create visual effects. Here UV light will not help, because it is invisible (although there is a fundamentally wrong term in the home - visible ultraviolet). The easiest way to do this is in two ways.

On the phone.

The first way is to use special applications that control the color of the display glow. Most users agree that the quality of the glow in this case is not good. Although here much depends on the type of screen.

A more effective way is to use the "flash" of the phone. Its emission spectrum captures the ultraviolet region. To highlight this area, you need to make a simple filter. To do this, you need to tape the flashlight of the smartphone with a transparent stationery tape and paint it with a marker of a suitable color (blue or purple). Another layer of transparent tape can be glued on top - to protect the filter from mechanical influences. To better match the emission color by experimenting, you can make a multilayer cake of pieces of tape colored in different shades. But you must remember that each layer absorbs some of the light and reduces the brightness.

On an ordinary flashlight

The same method is suitable for an ordinary handheld LED flashlight. In this variant you can use ordinary polyethylene instead of transparent tape. Even an incandescent lamp will do, but its spectrum is shifted to the red area and the intensity of violet radiation will be negligible.

It is not difficult to get a home-made UV source or imitation device on your own. Skilful hands and a little imagination - this is enough for success.