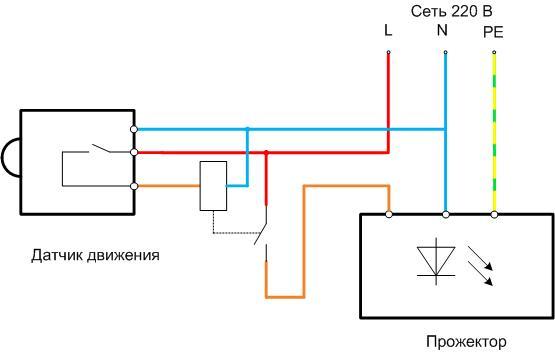

Wiring diagram of motion sensor to LED spotlight

Using a motion sensor in conjunction with a street light can, in many cases, result in significant energy savings. The sensor detects the presence of people or cars where they are not constantly present - in the entrance of a house, in the passage between the garages, in the storage areas. The command to turn on the light is given only when necessary. If the project does not provide such a detector, you can connect a motion detector to the outdoor or indoor LED spotlight.

Options for spotlights with motion detector

At the moment there is an active displacement of LED spotlights illuminators, built on a different elemental basis - incandescent lamps, halogen, etc. Within the framework of the topic under consideration there is no fundamental difference between them - the connection of the motion sensor to any spotlight is the same. But the low power consumption of LED-devices in many cases allows you to connect sensors to their own contact group and not to strengthen the load capacity of intermediate relays.

It is advisable to choose motion sensors combined with photo relay. It will turn off the spotlight during daylight hours and additionally save power without manual control. It will not affect the wiring scheme. It is also convenient to use detectors with adjustable delay to turn off to leave the monitored area when the light is on.

How to connect a sensor to a spotlight

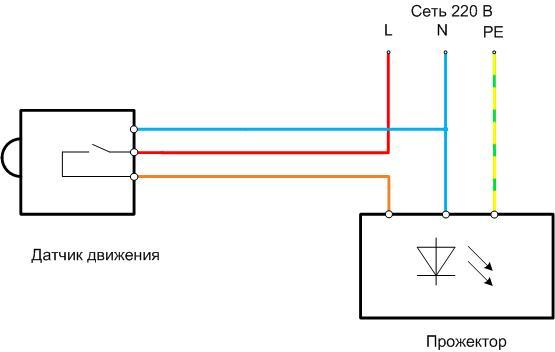

The output contact group of the detector serves as a power switch for the spotlight. But you can't connect the sensor with two wires - most sensors need 220 volts power (except for battery-powered devices). Therefore, you will have to pull three conductive wires to the motion detector:

- phase;

- zero;

- The power line from the sensor to the spotlight.

Ground is not necessary for most sensors.. Therefore, you can use a three-core cable. It is better to find a cable with different colors of core insulation, but not containing a conductor with yellow-green markings used for PE lines. It will not affect the performance of the system, but in the future it may mislead specialists during repair work.

The final scheme looks like this. The cross-section of the cable is selected from the conditions:

- The cable must be designed for the full power consumption of the illuminator;

- The voltage drop on the double length of the line must not exceed 5% (or better still, even less), otherwise the luminous flux Otherwise, the luminous flux of the spotlight will be noticeably reduced;

- for mechanical strength reasons, the cross-section of the conductors should not be less than 2.5 sq.mm.

Capacity of copper wires with different cross-sections is shown in the table. Do not use aluminum for lighting systems.

| Conductor cross-section, sq.mm | Maximum power at 220 V, W | |

| With open laying | With laying in pipes | |

| 0,5 | 2400 | - |

| 0,75 | 3300 | - |

| 1,0 | 3700 | 3000 |

| 1,5 | 5000 | 3300 |

| 2,0 | 5700 | 4100 |

| 2,5 | 6600 | 4600 |

| 4,0 | 9000 | 5900 |

From the table it can be seen that a 2.5 sq.mm conductor in the worst case is enough to power a luminaire with power of 4600 W. When using LED spotlights, this is enough to create a luminous flux equivalent to that of an incandescent lamp of about 36,000 W. Therefore a 2.5 square foot cable (minimum mechanical strength) covers 99+ percent of the reasonable needs of luminaire power requirements. And only in the case of very long lines and very powerful consumers may have to increase the cross-section to 4 sq.mm. The best way to check the line for voltage loss is to use an online calculator. You will need the initial data:

- the total length of the line (from the power point to the sensor and from the sensor to the spotlight);

- cross-section and material of the conductors;

- load current (power of the illuminator).

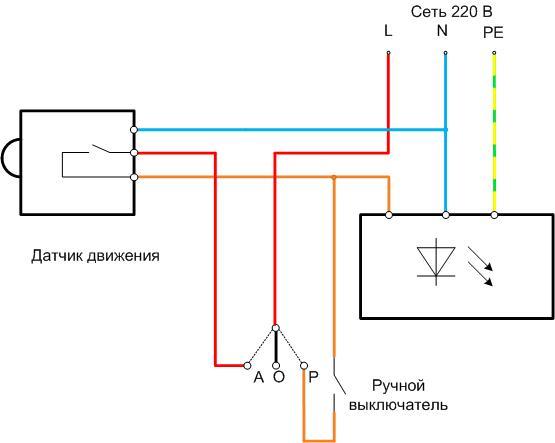

Even better is to build a circuit with the possibility of outputting to manual control mode and an additional switch. For this you will need a three-position switch.

With the switch in manual mode (P), you can control the lighting with an additional switch. Not superfluous will be this fashion and in case of failure of the photo relay - for the time of repair. To put the system out of operation is used position O. If you do not need such a mode, you can do with a switch with two positions (P-A). Mode selection switch and manual switch can be located in a separate lighting control panel.

If the contact system of the motion sensor does not allow you to switch the full load of the spotlight, you will need to switch it through a repeater relay, which can be used as a starter.

The starter can also be located in the switchboard. A scheme with an intermediate relay and a three-position switch can be combined.

Connecting several sensors to one spotlight

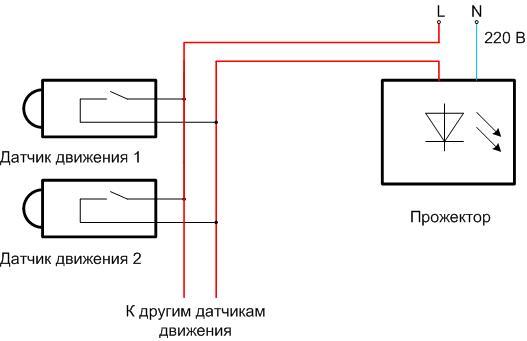

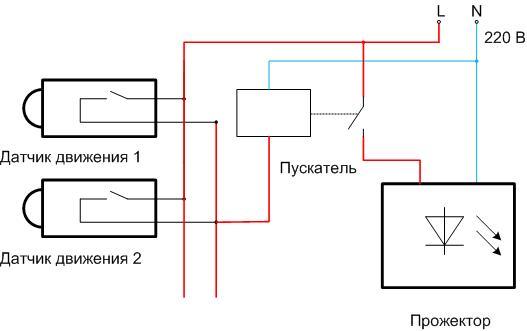

There are situations where you need to monitor several zones to control one spotlight. For example two entrances to a garage complex, or a car entrance and a pedestrian entrance. It may be that one sensor can not cover all zones. In this case, it is necessary to install several sensors so that each sensor controls its own territory. There are two options when connecting such sensors:

- When the output contact group of each sensor is designed to switch the full power of the spotlight, the contacts can be connected in parallel (installation OR circuit).Connecting two or more sensors directly to the illuminator (the N conductor to the sensors is not shown for simplicity).

- If the load capacity of the contact group of at least one or more detectors does not allow to work with the selected illuminator directly, the sensors are also connected in a "mounting OR" circuit. But control the illuminator via an intermediate relay or starter.Connection of two or more sensors to the illuminator via a repeater relay (the N conductor to the sensors is not shown for simplicity).

Important! It is a bad idea to connect two motion sensors controlling one zone in parallel without an intermediate starter in order to "increase the load capacity" of the contact groups. No adjustment will make the sensors actuate perfectly at the same time. This will cause one of the detectors to activate earlier. As a result, both contact groups will fail.

Configure the motion detector and eliminate false alarms

The motion sensor is configured according to the manufacturer's instructions. You should familiarize yourself with it before you start using the system.

- In most cases it is necessary to adjust the sensitivity of the device - so that it does not react to small animals, birds flying over, small objects carried by the wind, etc. Sensitivity adjustment is made for any type of sensor.

- Some sensors have a deactivation delay setting. This feature is convenient so that a person or vehicle can be guaranteed to leave the sensor's control area without turning off the light. It is adjustable based on local conditions ranging from a few seconds to a few minutes. It is advisable to initially set the adjustment to a minimum value, and then increase based on experience.

- If the motion sensor is combined with a photo relay, you must set the triggering level. This is done in the evening when the desired light level is reached. Turn the adjustment knob to turn on the light (it may be necessary to simulate the movement of objects in order to trigger the detector). If necessary, the triggering level can be adjusted more accurately on subsequent evenings.

If the setting is done correctly and carefully, false alarms should be minimized. If unauthorized light triggering has not been completely avoided, you can try to adjust the position and direction of the sensor's viewing sector so that:

- extraneous light sources (headlights of passing cars, etc.) do not fall on it;

- it does not have periodic heat sources (chimneys, heating pipes, etc.) in its field of view;

- small animals had no possibility to get close to the sensor.

Video example of connecting the sensor.

You should also analyze local conditions, figure out what could be the source of interference and take appropriate measures. The reward will be long and trouble-free operation of the automatic lighting system.