Description of DRL lamp

DRL light sources are very reliable and efficient and are used widely in many different applications. In order to use them properly, however, it makes sense to get to know the devices in more detail.

What is a DRL lamp

The abbreviation DRL stands for "arc mercury lamp. Sometimes there is an abbreviation RL. In some documents, the "L" stands for "phosphor," since it is the main source of light in the device. The element belongs to the category of high-pressure discharge lamps.

The marking of a particular model contains a number denoting the power of the equipment.

Pros and cons

DRL sources have long been used for street and room lighting. During this time, users have had time to highlight the advantages and disadvantages that determine the choice:

Advantages:

- good light output;

- high power;

- relatively small housing size;

- Low price in comparison with LED;

- economical power consumption;

- Most of the products are capable of operating for 12,000 hours (the figure depends on the quality of the components used).

There are also disadvantages, which are important to consider:

- harmful mercury vapor is present inside the bulbs and can cause poisoning in the event of a leak;

- It takes some time from switching on until the lamp reaches rated power;

- The preheated lamp cannot be switched on until it cools down (about 15 minutes);

- are sensitive to voltage fluctuations (a deviation of 15% will cause a 30% change in brightness)

- equipment does not work well at low temperatures;

- during operation there is a pulsation of light;

- low color rendering;

- elements become very hot;

- The circuit should use specialized heat-resistant components (wires, sockets, etc.);

- arc element requires a ballast;

- Sometimes an energized cell makes an unpleasant sound;

- The room in which the lamps are operated must have ventilation to ventilate the ozone;

- over time, the phosphor loses its properties, which leads to a weakening of the luminous flux and changes the spectrum.

Most of the disadvantages are inherent only in cheap CRL from dubious manufacturers and are insignificant when you need a powerful light source.

Lamp design

Early designs used burners with two electrodes, which required an additional pulse generation module to be installed when switching on. The voltage these created was much higher than the operating voltage of the lamp.

Two-electrode units were later replaced by four-electrode units. It became possible to eliminate the need for external equipment generating pulses for ignition.

The DRL lamp consists of the following components:

- main electrode;

- ignition electrode;

- electrode leads from the burner;

- Resistor that provides the required circuit resistance;

- inert gas;

- mercury vapor.

The main bulb is made of durable glass, resistant to high temperatures. Air is evacuated and replaced by inert gas. The main function of the inert gas is to prevent heat exchange between the heater and the bulb. Even so, the body of the equipment can be heated up to 120 degrees Celsius during operation.

To connect the lamp to the mains there is a base. It allows you to fix the equipment in the socket and provides the tightest possible contact.

The inside of the bulb is covered with a phosphor, which translates the invisible ultraviolet radiation into visible light. When exposed to UV light, the phosphor heats up and begins to emit light. The hue of the light depends on the composition of the coating.

The main luminous element inside the bulb is the electric arc between the electrodes.

Mercury acts as a stabilizer of electron motion and can appear as small balls when the device is cold. When slightly heated, the mercury turns into vapor and interacts with the internal elements of the structure.

The burner itself looks like a small tube of glass or ceramic. The main requirements for the material: preservation of properties at high temperatures and the ability to pass ultraviolet rays.

Resistors in the circuit limit the current strength and prevent other elements from failing prematurely.

Principle of operation

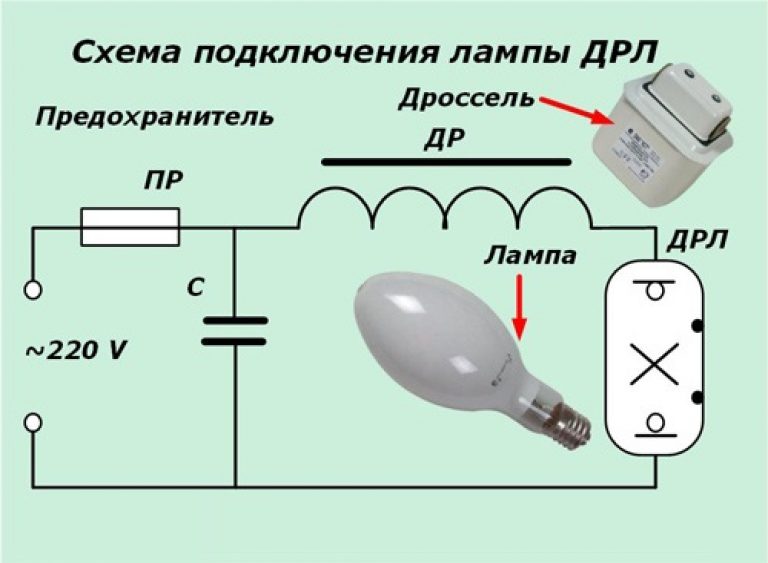

The basic principle of a radiant lamp is that there is a light source, a capacitor, a choke and a fuse.

When voltage is applied to the electrodes, gas ionization occurs in the free area. A breakdown and an arc discharge occurs between the electrodes. The discharge glow can be bluish or violet.

The phosphor is a red color. When mixing the spectra, the output is pure white light. The tint can change when the voltage applied to the contacts changes.

Topical video: Design, principle of operation and peculiarities of operation of ДРЛ lamps.

It takes about 8 minutes to reach the desired brightness in a DRL. This is due to the gradual melting and evaporation of mercury balls. It is the mercury vapor that ensures the stability of the processes inside the burner and improves the luminescence of the device. Maximum brightness appears at the moment of complete evaporation of mercury.

It is worth noting that the ambient temperature and the initial state of the lamp affect the speed of reaching the rated power.

The choke in the circuit is a primitive ballast. With its help, the system controls the amount of current flowing through the electrodes of the design. If you try to bypass the choke and connect the lamp directly to the network, it will fail very quickly.

Most electronic manufacturers are now moving away from the choke as an obsolete solution. The arc is stabilized by electronic devices which ensure the correct values even if the line voltage changes significantly.

Technical data

The main technical characteristic of sources of this type is the power. It is specified in the marking of the device next to the abbreviation DRL. The rest of the parameters should be considered separately. They are indicated on the box or in the passport of the equipment.

These include:

- Luminous flux of DRLs. Determines the efficiency of the device when illuminating a specific area.

- Resource. Service life of the equipment if basic recommendations are followed.

- Socket. Designation of the way the model is built into the lighting equipment.

- Dimensions. Less important characteristic, which defines the use of the model in specific luminaires.

ДРЛ 250.

Technical characteristics of DRL 250

| Power, W | Luminous flux, Lm | Service life, h | Dimensions (length × diameter), mm | Socket |

| 250 | 13 000 | 12 000 | 228 × 91 | Е40 |

DRL 400

Technical characteristics of DRL 400 lamps

| Power, W | Luminous flux, Lm | Service life, h | Dimensions (length × diameter), mm | Socket |

| 400 | 24000 | 15000 | 292 × 122 | Е40 |

Scope of application

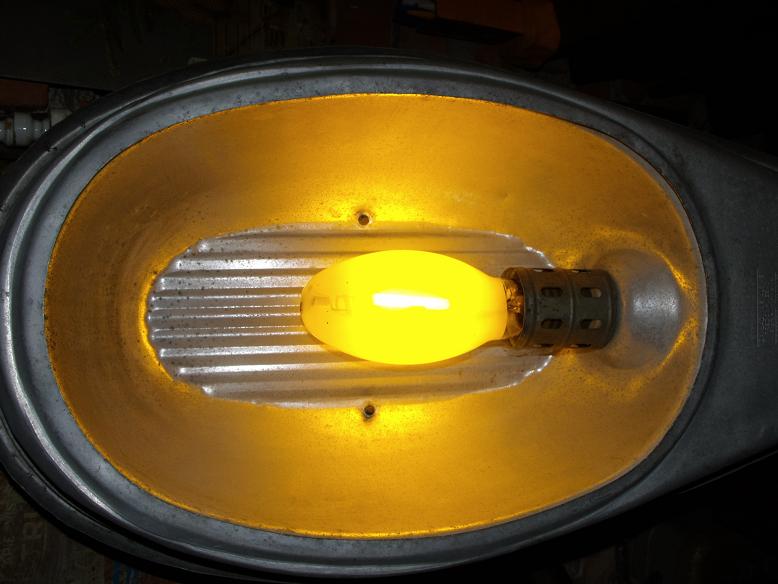

All the DRL sources are used for lighting large areas. Most often they are installed in street lamps, road lighting systems and gas stations. Often organized lighting in large warehouses and other premises where the parameter of color rendering is not crucial, as well as in the exhibition centers. High power devices is very helpful.

In homes and apartments they are not used, as poor color rendering and long turn-on make this solution ineffective.

Lifetime

The service life of DRL lamps directly depends on the wattage. The most common DRL 250s are capable of working for about 12,000 hours without any malfunction. However, it is important to remember that the following factors can reduce the service life:

- frequent switching on and off;

- voltage fluctuations;

- Continuous use at low ambient temperatures.

All this leads to accelerated degradation of electrodes and, as a consequence, rapid failure.

Disposal

The presence of mercury in LEDs makes them a Class 1 hazard. In some countries, such devices are prohibited for use. However, observance of the rules of operation and disposal minimizes all risks to people and the environment.

These light sources should not be disposed of with normal household waste. The mercury in the environment can be very harmful to the environment.

The same companies that are responsible for disposing of other energy-saving lamps also dispose of DRLs. The company must have a state license authorizing such work.

In large cities, you can find special bins in which the end-of-life elements are placed. You can also contact utilities, lighting manufacturing or repair firms, or hazardous waste disposal organizations.