Description of the glow of a neon bulb

What is a neon lamp

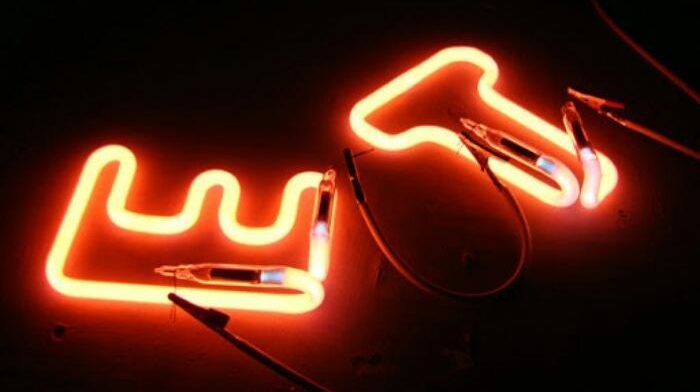

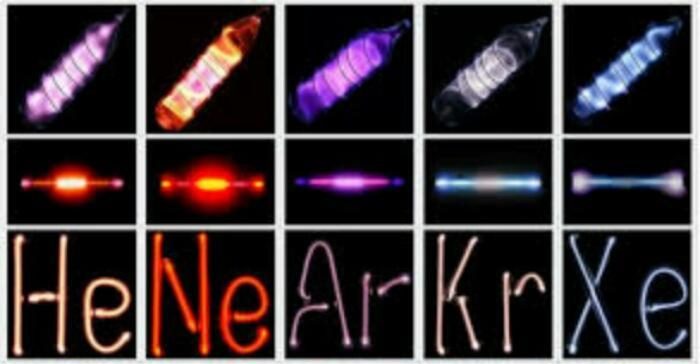

A low-pressure discharge tube filled with the inert gas neon is a classic neon tube - a lamp that produces a uniform orange-red neon light along its entire length. The inert gases used in lighting devices include helium, xenon, argon and krypton, but they have a different glow spectrum, which allows you to combine them and create different colors.

Structurally, neon is no different from other discharge lamps, including fluorescent lamps. A current of 0.1 to 1 milliampere is needed to start the device. This sensitivity has made it possible to use neon lamps in line voltage indicators, provided that a step-down resistor is used to protect against electric shock.

At the same time, the ignition voltage, depending on the length, diameter and gas filling of the bulb can reach 12,000 volts. Therefore, starting and maintaining the device requires the presence of an inverter in the circuit. The main use of neon lighting was in advertising and entertainment in Europe and the United States. In Russia, this fashion spread with a delay of ten to fifteen years, although in industrial devices glow discharge and indication technology has been used since the 50s.

Where does neon come from

The first neon was made in 1910 by Georges Claude, but for his invention he used the work of Maurice Travers and William Ramsay, British chemists who obtained neon by eliminating it from the air as a by-product. In atmospheric air, the maximum concentration of Ne reaches 0.00182%. This is very small on the scale of the planet, but sufficient for its extraction on an industrial scale.

The method of producing neon is to liquefy all the heavy components of air, resulting in a residual non-liquefied component - the helium-neon mixture. Three methods are used to separate helium and neon:

- adsorption of neon by cooled activated carbon;

- freezing with liquid hydrogen;

- double distillation in an evaporator-condenser;

- cold rectification of the compressed mixture.

It is the latter technology that produces 99.9% pure gas on an industrial scale.

Video: Neon - the most INERT gas on Earth

Types of neon

Any luminous colored tube, sometimes bent in the right way, is mistakenly called a neon. In its classic form, however, such a lamp is made of a glass bulb filled with inert neon, with two or three electrodes at its ends. Indicator bulbs are smaller than the LED element, and the discharge tubes are up to ten meters long and 20 mm in diameter.

When the flask is made, it is shaped by heating the glass on a gas torch, filled with neon, and a few drops of mercury are added to brighten the glow. The device is unstable to mechanical impacts, and its disposal requires special safety measures related to the toxicity of mercury vapor. However, the simplicity of the device limits its longevity to the integrity of the bulb, the composition of the electrodes, and the serviceability of the triggering elements. There is literally nothing to burn out in a classic neon, so their correct operation can continue uninterrupted for up to 80,000 hours.

Flexible

The difficulty of operating glass lamps has led to the invention of alternative technologies that mimic neon lighting. As a replacement, LED strips embedded in polyvinyl chloride or silicone strips became popular, scattering the beams of the bulbs so that the light is distributed evenly over the surface of the strip. The so-called flexible neon:

- easy to install - installed in special fixtures or grooves with a bend of 180 ° and a bending diameter of 10 mm;

- mechanically stable and airtight;

- affordable;

- economical in terms of power consumption - 50 cm long strip is powered from a standard USB-connector with a voltage of 3-4 volts.

Cold

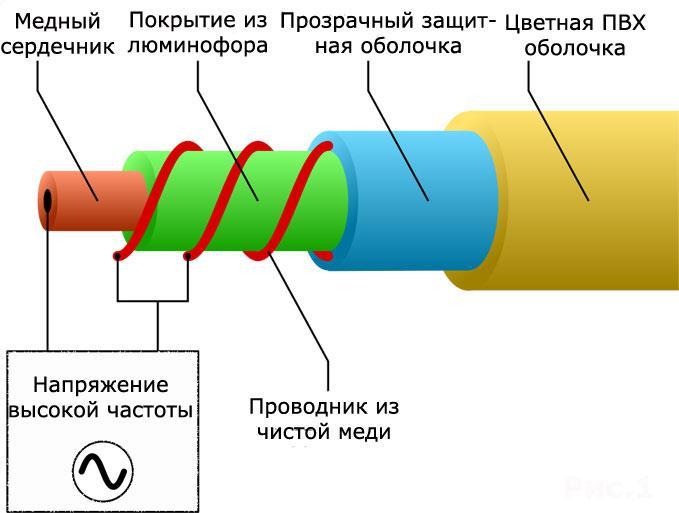

A variety of flexible neon, but technologically executed on a different principle. As a source of light uses phosphor, which is covered with a flexible copper wire. On top of a layer of phosphor and transparent dielectric thin copper wire is wound in a spiral. The entire structure has a transparent plastic sheath. The coil with the rod works on the principle of a magnetic coil, and it is the magnetic field that excites the luminescence of the phosphor.

Cold neon operation is possible when connected to the network through special inverters, producing a current frequency of up to 6000 Hz. The lamp itself is a flexible, durable and sealed cord with different colors of glow depending on the type of phosphor.

The diameter of the cord is often regulated by manufacturers only by the thickness of the outer shell, the inner part remains the same. Therefore, it makes sense to take a thick cord only if it is justified by the size of the design slot.

A characteristic feature of cold neon is the complete absence of filament heating during prolonged operation. The only disadvantage of technology is that with frequent sharp bends in the small diameter phosphor coating is broken with the formation of darkened areas on the wire.

Where to use neon lights, examples with photos

Initially, the properties of neon lights determined their use in the field of electrical engineering as:

- indicators of mains voltage in electrical appliances;

- control-indicator devices for determining the presence of voltage on conductors;

- indicators of the presence of electromagnetic radiation - in the device Balizor neon glows when exposed to an electromagnetic field;

- a fuse in alarm circuits.

Neon lamps in modern times are used, for the most part, in trade, design and entertainment.

How a neon lamp works

The classic gas discharge neon uses neon's ability to emit photons of light when gas molecules exchange energy in a discharged environment under the action of electricity. When an alternating current is connected, the glow is distributed evenly throughout the bulb. If the current is constant, the glow is concentrated around the cathode.

Wiring diagram

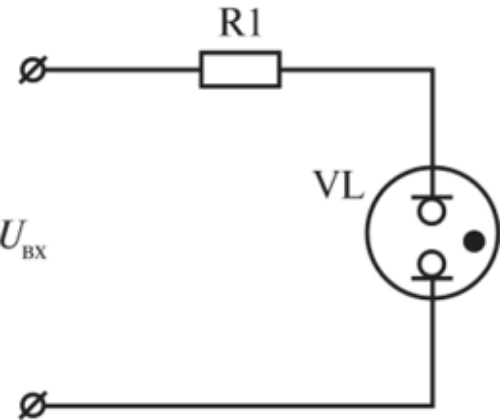

Indicator bulbs are connected through a step-down resistor according to the following circuit.

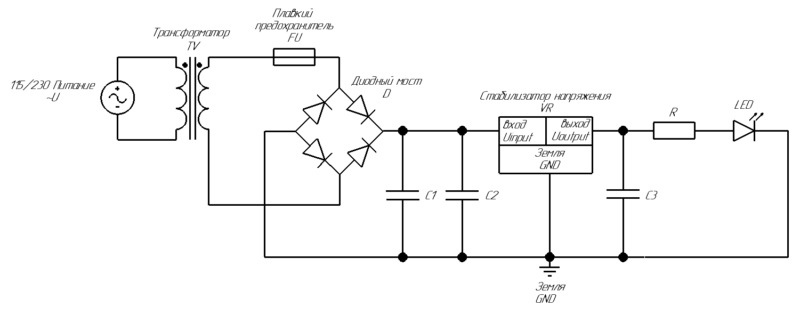

For example, lighting fixtures on LED elements require a more complex wiring scheme via a ballast, as in the figure below.

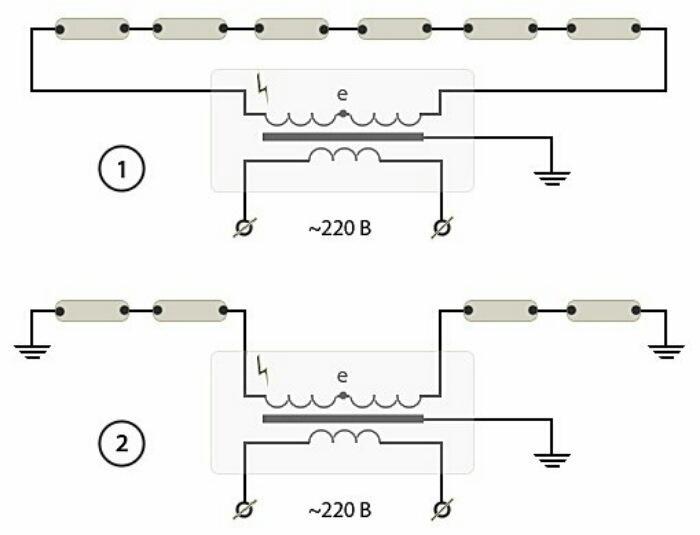

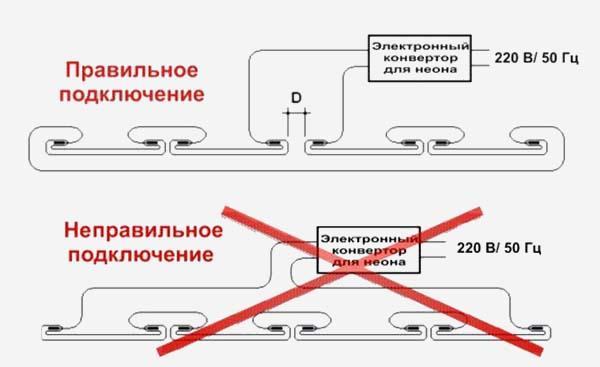

Connecting a gas discharge neon means a suitable power inverter in the circuit.

The first circuit is considered standard. The second allows you to reduce the length of conductors, and if one side of the circuit fails, the second continues to work.

Depending on the length and diameter of the discharge tube, it requires a step-up transformer with the capacity shown in the table.

Connecting electric lights to high-voltage devices requires knowledge of electricity and electrical engineering. If calculated incorrectly, the discharge can turn into an arc, followed by the bursting of the bulb.

Cold neon is connected through an inverter to a 12 or 24 volt power supply, depending on the length of the glow cord.

LED-neon is connected similarly to the LED strips, but all connections are made through connectors, followed by sealing the junction, as in the video.

How to get a different spectrum of light

RGB-ribbons in the presence of the controller are able to change the color, modes and intensity of luminescence of flexible neon imitation of lights or strobe lights. In discharge lamps, different noble gases or their combinations with the color of the glass bulb are used to produce different colors. For example, to obtain a green glow, xenon glowing blue is pumped into the yellow bulb.

Advantages and disadvantages

Gas-discharge neon emits a soft, and, so to speak, more analog light compared to devices of another type. Among the advantages of these lamps are:

- uniformity of luminescence along with the ability to concentrate light on one of the electrodes when using direct current;

- durability - no consumable elements in design;

- operation of small indicator lamps directly from 220 V mains;

- possibility of manufacturing bulbs and cathodes of various shapes;

At the same time, the device of gas-discharge lamps is not without disadvantages and is considered outdated for the following reasons:

- noise during operation from the step-up transformer;

- fragility of the glass bulb;

- the difficulty of disposal due to the presence of poisonous mercury vapor inside the design.

The main differences from the LED strip

Cord, working on the principle of phosphor glow under the influence of electromagnetic field in the same way as the discharge tube emits light at 360 °, but it bends in any direction and consumes less energy. The flexible LED strip emits light 180° to one side and bends only in one plane. The advantage of the flexible LED strip, imitating neon, is its mechanical stability, ease of operation and the ability to control the mode through the controller.

Of course, the RGB-ribbon system is limited by the direction and radius of curvature, as well as the narrow vector of glow, but these disadvantages are compensated by the possibility of creating unique light shows by using programmable controllers with different modes of operation. At the same time the luminous neon thread is thinner (up to 2 mm), and this allows you to mount it in narrow joints and slots, which is important in auto tuning and decorative upgrade of various devices.

It should be added that now the fashion for retro, including analog, is returning, so the old gas-discharge lights are not losing relevance in the field of design and marketing. Price and difficulty in operation have made classic neon lights the choice for wealthy customers who want to stand out for their status and good taste.