Conversion of monitor backlighting to LED

LCD monitors have a large part of the display market for desktop computers, laptops, TVs, information and advertising monitors, etc. Although there are more promising technologies, LCD screens will retain their position for a long time to come. These devices are reliable, but nothing in the world is everlasting. And expensive devices sooner or later break down. In many cases, they can be repaired yourself. Such situations include the failure of the backlight bulb.

The device of LCD display

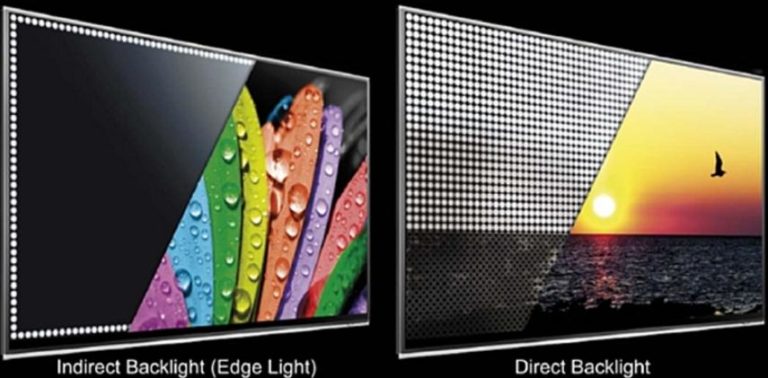

Before you figure out how to replace a faulty backlight, you need to understand why you need it in and how the LCD screen is arranged.

Liquid crystals are substances which have the property of fluidity, but the arrangement of molecules in them is ordered. The molecules in these substances have an elongated or disk-like shape. The principle of operation of an LCD display is based on the property of LC molecules to change their spatial orientation under the action of an applied electric field. In this way the polarization of the light passing through the LCD can be adjusted and an RGB image can be created.

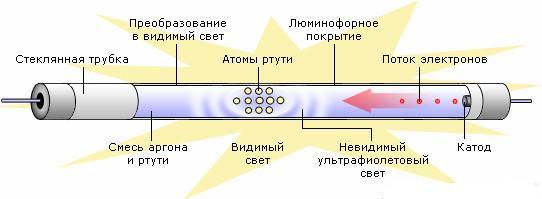

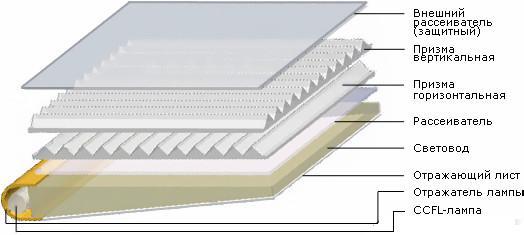

A lamp is what you need to create transmitted light. In most cases these are fluorescent lamps without cathode filaments (CCFL). Such a lamp is a sealed glass cylinder filled with an inert gas with a small admixture of mercury. To work it needs a voltage source of 600...900 volts (depending on modification), and for ignition a little more - 800...1500 volts. A diffuser system is used to create a uniform flux across the surface.

The lamp is the most short-lived link in the system, but it is not so difficult to change it for a faulty one yourself.

Signs of backlight failure

The user may encounter the following phenomena:

- when turning on the monitor, the power indicator lights up, but the screen remains dark;

- the display turns on, the image appears on it, but after a few seconds it goes out.

In the first case, there are serious reasons to assume that you need to repair the backlighting of the monitor, although the malfunction may be in the power supply of the light source. In the second case, the probability of lamp failure is 90+ percent. Also a high probability of light source failure is indicated by a dull glow of the whole display or half of the display, as well as the fading of half of the display.

Replacing the light source in the monitor yourself

The first thing to do is to get to the old lamp. If it is a TV, computer or laptop monitor, you need to stock up on tools:

- a small Phillips screwdriver;

- two screwdrivers with a flat, wide slot;

- Scalpel, tweezers and other tools for disassembly.

Important! It is necessary to disassemble monitor with power supply completely turned off. Lamp pins may carry life threatening voltage.

The plastic cover is removed from the monitor with two flat, non-thick screwdrivers - you must press the latches without applying excessive force.

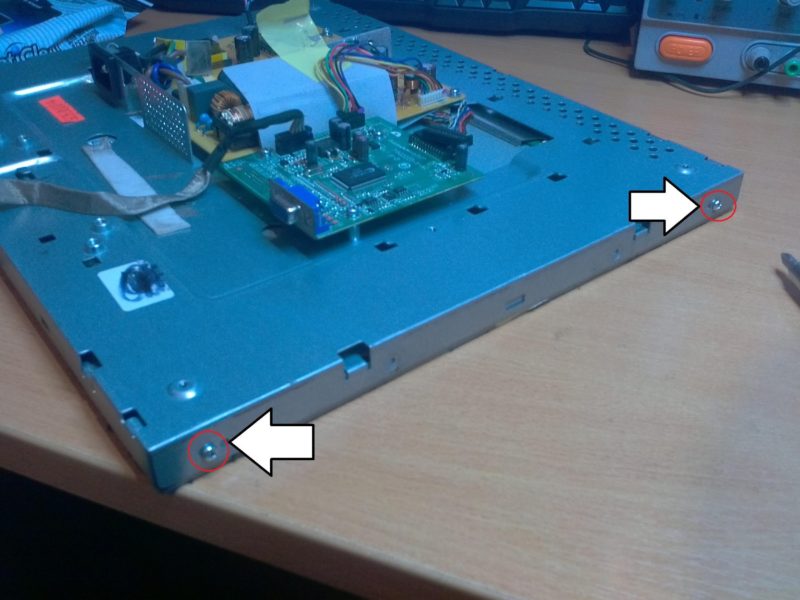

The next step is to remove all connectors and unscrew all small self-tapping screws from the back and all sides.

And then remove all the covers and dismantle the matrix.

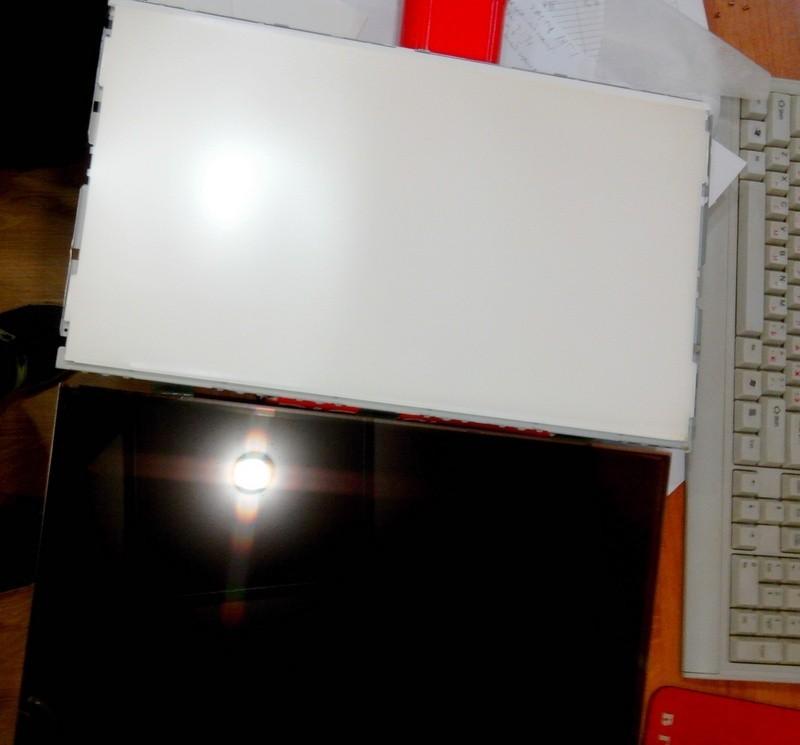

By removing the polarizing film, diffusers and light guides, you can get to the lamps. Sometimes traces of failure can be found visually - in the form of black spots.

Next, we take serviceable lamps and install them in place of the failed ones. You can use the table to select lamps by size, depending on the size of the diagonal screen in inches.

| Display diagonal screen size, inch | Lamp diameter, mm | Lamp length, mm |

| 14,1 | 2,0 | 290 |

| 14.1 Wide | 2,0 | 310 |

| 15-15,1 | 2,0 | 300, 305, 310 |

| 15 – 15,3 | 2,0 | 315 |

| 15 – 15,3 | 2,6 | 316 |

| 15,4 – 16,3 | 2,0 | 324, 334 |

| 15.4 Wide | 2,0 | 334 |

| 16,3 – 17,0 | 2,6 | 336 |

| 17, 17,4 | 2,6 | 342, 345, 355, 360 |

| 17,1 Wide | 2,0 | 365, 370, 375 |

| 18-19 | 2,6 | 378, 388 |

Reassembly is performed in reverse order. And if everything was done carefully and the problem was only in the lamp, the monitor will last for a long time.

Before reassembling it is recommended to blast all parts and the inside of the housing thoroughly from dust.

Checking Lamp Conditions

If there are no external signs of the lamp damage it is worth checking your dismantled lamp for serviceability. Yes, and check the new device does not hurt either. You can not do it with a tester or oscilloscope, so you need to apply high voltage to the contacts of the lamp. To do this you need an inverter. There are various ways to find one:

- Buy a ready-made inverter in a store or on the Internet. For a one-time repair is not economically feasible.

- At a repair shop buy a damaged unrepairable monitor. In most cases it will cost pennies. It will have to be disassembled and the voltage converter removed.

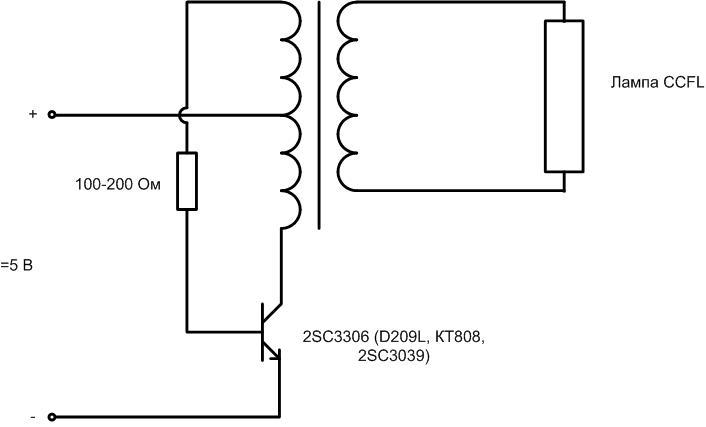

- If you have skills in working with electronic components, you can assemble a simple inverter yourself. Its circuit diagram is not complicated.

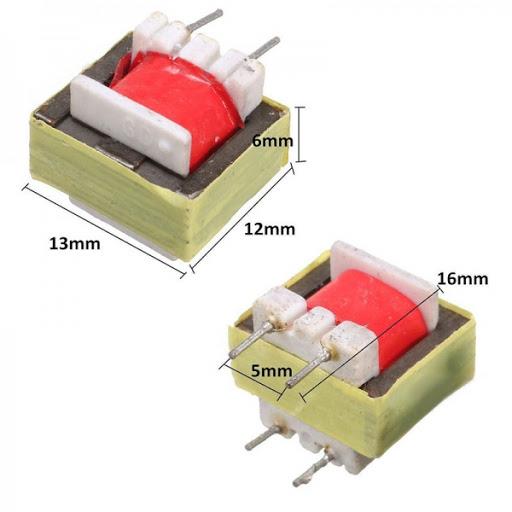

The most labor-intensive element is the transformer. It will have to make it yourself. It can be wound on iron from a small-sized industrial transformer, for which you will have to remove all the regular windings.

Primary winding contains 30-40 turns with tap-off from the middle. The oscillation amplitude on it will be about 3 volts. Therefore, to get 1000 volts on the secondary winding it must contain 1000/3=333 times more turns than the primary. With 30 turns in the primary it will be necessary to wind about 10,000 turns of the secondary. This number may need to be adjusted. It is more convenient to experimentally change the ratio by varying the primary. To do this, you must first wind the secondary and then the primary on top of it. On the Internet you can find diagrams and other voltage converters of varying complexity to test CCFL lamps.

The use of LED light sources in LCD monitors

Due to the widespread proliferation of LED lighting equipment, the idea of replacing obsolete gas-discharge lamps with LED lights often arises during the repair. This idea has a right to life, and to implement it is not difficult. But replacing bulbs with LEDs in the monitor will require solving several issues.

- Dimensions. CCFL lamp is installed inside a special profile. The width of this groove comes in 7 mm or 9 mm. The width of the ribbon should be able to install it in the groove of this profile. In some cases it is possible to to trim the edges of the "oversized" webbing to 1 mm on each side so as not to damage the conductor rails. If all works well, the strip will fit well into the profile.LED strip installed in the profile.

- Obtaining uniform illumination. The LEDs on the web are spaced apart, so when using a conventional strip, it is easy to get streaky flux distribution, despite having an effective diffusion system. To avoid this, you will need a fixture with at least 120 elements per meter (minimum 90).

Power Source. Replacing the lamps in the monitor with a low-voltage LED strip will require a lower supply voltage than the CCFL. This voltage can be looked up on the OEM display board, but the strip power should not be less than 10 watts, as the light flux in the scattering system is severely attenuated. It is not certain that the load capacity of the OEM power supply will be sufficient. Therefore, in some cases, a separate remote power supply for the appropriate voltage is used to power the LED strip. The disadvantage is obvious: the backlight is switched off separately from the monitor, and there is no brightness control (or you have to make a separate circuit for it). The brightness problem occurs with the first variant as well, but in both cases it is not difficult to solve.

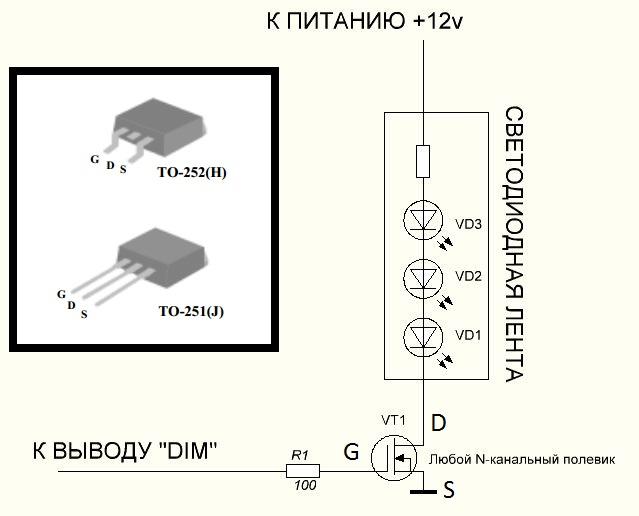

The brightness of the original CCFL is regulated by PWM which is done by a special circuit in the inverter. In this case the inverter must be removed and the PWM signal can be used for its own purposes. To do this, you must find a connector on the board, next to one of whose pins will be labeled DIM. There is a PWM signal on it which can be monitored with an oscilloscope. To this point it is necessary to connect the negative terminal of the tape through a transistor switch. MOSFET transistor with N-channel can be used as a key element. It must be rated for the full current of the ribbon section with an allowance. The AP9T18GH fuse - found on failed computer motherboards - will cover 99+ percent of cases. It can handle loads up to 10A.

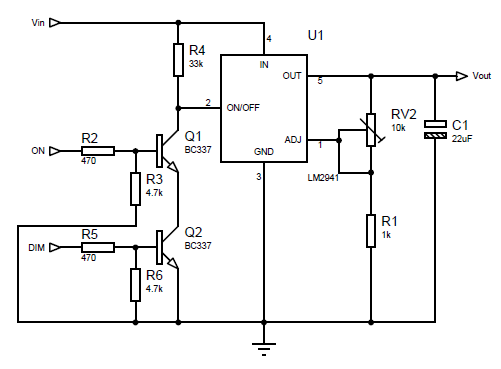

If you have skills and knowledge you can use the regular scheme of brightness control and switching on/off backlighting, adding two transistor switches to it and setting the output voltage of 12 volts.

In this case you will not need any additional and external devices for modification, and the monitor will work in standard mode. You just have to apply DIM and ON signals present on the connector to the switch input.

Important! LED strips have different color temperatures, so after installing in the monitor the screen colors may change slightly. You can try to solve this problem with the regular settings of the display or take it into account in the future. To avoid this problem, you should focus on neutral-white glow colors when buying.

To reinforce the information, video: Replacing a worn out LED backlight board on your LCD TV with a standard LED strip.

Replacing the regular backlight bulbs with similar or LED bulbs can't be called simple. In fact, it is a labor-intensive process that requires knowledge and skills. Still, for the average wizard it is quite achievable, and after repair the display will last for many years. If necessary, the repair of newly installed LED backlighting monitor will not be difficult - the experience will be gained.