What does the abbreviation DNAT mean

Sodium lamps are a type of energy-saving lighting element with sodium inside the bulb. The design is old and is being replaced by more technologically advanced light sources. However, it is still in demand, so it makes sense to look at it in detail.

What is a sodium lamp

Sodium lamp refers to a lighting device with the designation DNaT and the transcription "arc sodium tubular" lamp. The element is characterized by its reliability, simplicity and affordability. Many companies are still producing them, which shows that there is demand.

The devices first appeared in the thirties, but they were quickly superseded by metal halide sources. Elements are used for street lighting, highlighting crops, in sports halls and underpasses.

For a long time, sodium elements were installed in street lights and track lighting systems. Now the devices are being replaced by LEDs. Nevertheless, a large number of planners prefer sodium sources due to their affordability, long service life, high power and light output.

It is not uncommon for DNATs to be installed in factories along with metal halide lamps. Sodium lighting provides warmer shades and is more comfortable to work with.

Varieties

All sodium lamps are divided into high-pressure and low-pressure elements. The main difference is the pressure level in the bulb and the difference with the atmospheric value. This determines the specifics of the equipment and application in specific situations.

High Pressure

High-pressure elements come in three types:

- DNaT - the most common high-pressure arc sodium lamp, which can be found in street lamps.

- DNaZ is a variation of DNaT, which has a mirror coating on the inner wall of the bulb. The element is characterized by lower power, but higher light output.

- DRI (DRIZ) is a device with emitting additives. May have a mirror layer on the bulb. Relatively good color rendering, but some colors look dull.

Low

Sodium Low-pressure lamps were not popular with users from the beginning and are no longer used. Even the increased energy efficiency was not a reason to use them. The reason is poor color rendering, in which it is difficult to identify the color and sometimes the shape of an object.

At the same time, they are reliable, consume little energy, and give off excellent light. Rarely used solely for street lighting.

Technical characteristics

The main include luminous flux, light output and operating time. There is a direct correlation between the power of the element and the life - models of high power work longer.

Below are the technical characteristics of the most popular sources of DNAT with 150, 250 and 400 watts. They are all connected to the luminaire by means of an E40-type base at 120 V.

DNAT 150

Technical characteristics of lamp DNAT 150

| Power, W | Flux, lm | Luminous efficacy, lm/W | Length, mm | Diameter, mm | Power duration, h |

| 150 | 14 500 | 100 | 211 | 48 | 6 000 |

DNAT 250

Technical characteristics of lamp DNAT 250

| Power, W | Flux, Lm | Luminous efficacy, lm/W | Length, mm | Diameter, mm | Power duration, h |

| 250 | 25 000 | 100 | 250 | 48 | 10 000 |

DNAT 400

Technical characteristics of lamp DNAT 400

| Power, W | Flux, Lm | Luminous efficacy, lm/W | Length, mm | Diameter, mm | Power duration, h |

| 400 | 47 000 | 125 | 278 | 48 | 15 000 |

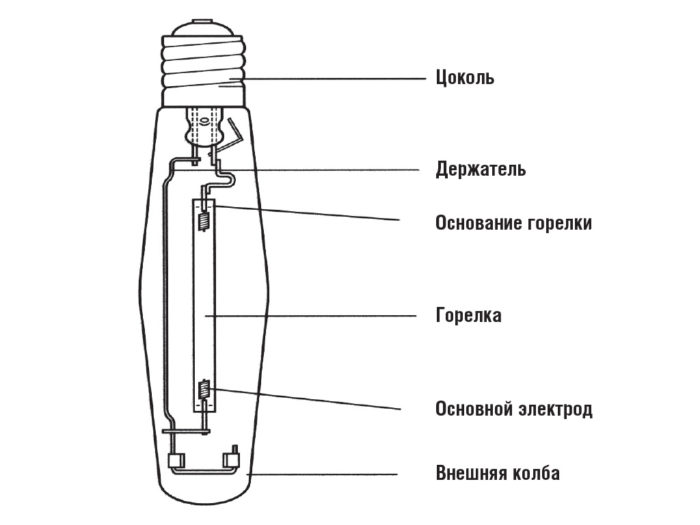

Design Features

All sodium lamps have a high-strength aluminum oxide bulb connected to two electrodes. The cell material withstands high temperatures and is resistant to sodium vapor. The bulb is filled with a mixture of inert gases, mercury, sodium, and xenon. The presence of argon in the gas mixture facilitates charge formation, and mercury and xenon serve to improve light output.

The design looks like a bulb within a bulb. The burner is installed in a smaller flask, in which a vacuum is created. It is connected to the mains through the base plate. The outer element acts as a thermos, protecting the internal parts from the negative effects of low ambient temperatures and reducing heat loss.

Burner

The burner is the most important component of any DNAT lamp. It is a thin glass cylinder which is as resistant to temperature variations and chemical influences as possible. Electrodes are inserted on both sides of the bulb.

When manufacturing the burner, special attention is paid to its complete vacuumization. The base during operation of the equipment heats up to 1300 degrees and ingress of even a small amount of oxygen in this area can lead to an explosion.

Video: DNAT 250 lamp with depressurized bulb.

The burner is made of polycrystalline aluminum oxide (polycor). The material is high in density, resistant to sodium vapor, and transmits about 90% of all visible radiation. The electrodes are made of molybdenum. Increasing the power of the cell requires increasing the size of the burner.

The vacuum in the bulb is difficult to maintain because the temperature expansion inevitably creates microscopic gaps through which air passes. To prevent this, gaskets are used.

Plinth

Through the plinth, the lamp is connected to the power grid. The most common connection used is an Edison screw connection marked E. E27 socket is used for DNAT 70 and 100 W, E40 for 150, 250 and 400 W. The number next to the letter designation indicates the connection diameter.

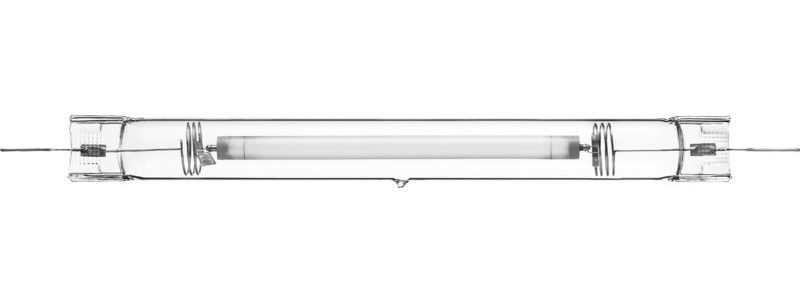

For a long time sodium lamps have only had screw bases, but now we have a new connection called Double Ended with contacts on both sides of the cylindrical bulb.

How it works

Inside the bulb of a sodium lamp an arc discharge must be maintained. A pulsed ignition device (PED) is used for generation. During switching on, the pulse can reach a power of 2-5 kW.

Under the influence of the voltage a breakdown occurs with the formation of a discharge. It takes about ten minutes for the burner to warm up and for the device to reach nominal power. During this time, the brightness increases and normalizes.

In modern elements can be found a built-in choke, which limits the arc current strength and guarantees a stable supply of energy without pulsations and other undesirable moments.

Applications

Sodium lamps are used when economic considerations are more important than color rendering. They are not suitable for residential areas, public buildings or production halls. In addition to poor color rendering, the lamp is dangerous if it malfunctions.

DNaT are used for organizing Outdoor or greenhouse lighting, illumination of architectural monuments and buildings. They are especially common in large cities. They can be recognized by their yellowish-golden hue. Most common elements are 250 and 400 watts.

Relatively recently, low-power sodium lamps with a color rendering index of 80 have appeared on the market. This index is significantly higher than that of other similar models. Therefore, these lamps are effective for light decoration in public places.

Sodium light sources are used in the last stages of seedling growth in greenhouseswhere shades of blue are often present. Radiation of a significant portion of the ultraviolet spectrum promotes plant growth. It is important to handle the elements with care because the destruction of the bulb can ruin the entire crop and spoil the soil.

Sodium elements are often used by designers to simulate fire or sunlight.

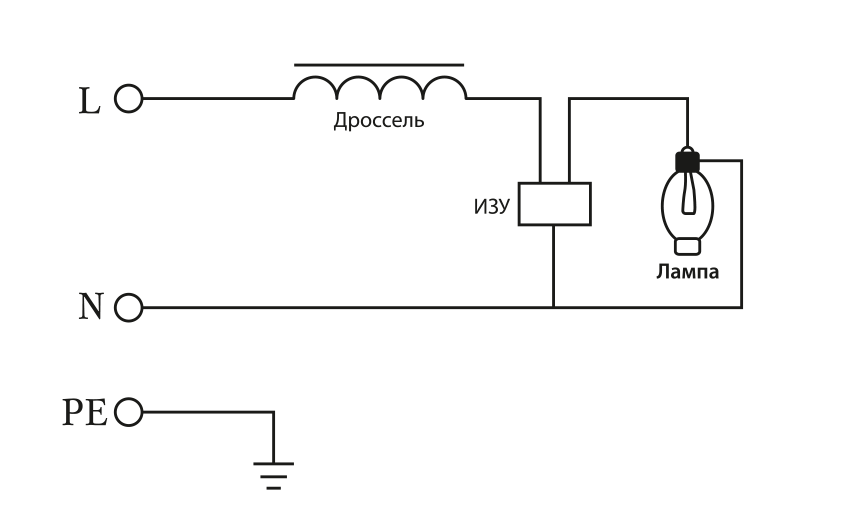

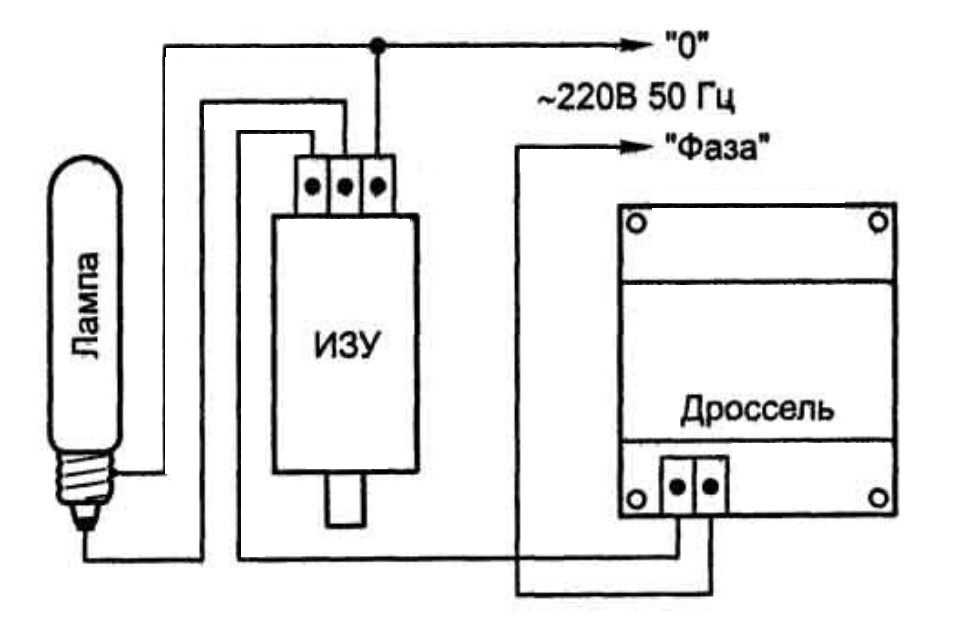

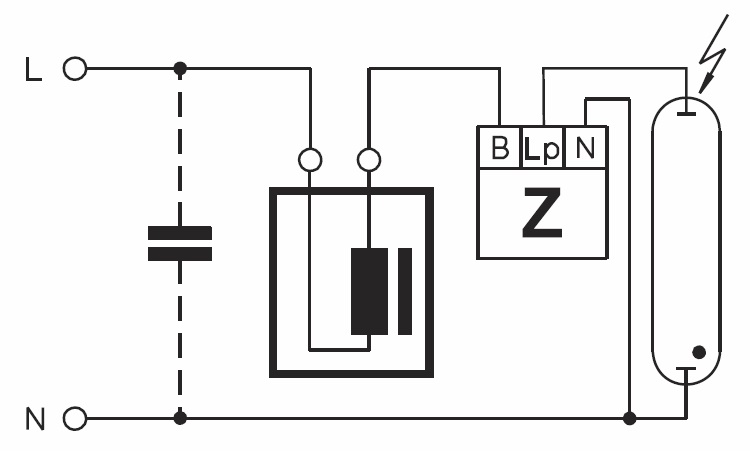

Wiring Diagrams

Wiring diagrams vary depending on the DUT. The power supply can be two-pin or three-pin. Below are the diagrams for both cases.

In connection diagrams for sodium lamps, the choke is always connected in series while the ignition unit is connected in parallel.

The power reactivity during start-up requires a capacitor to be included in the circuit to reduce the interference and the inrush current. Usually an element with a capacity of 18-40 µF is used. The capacitor is connected in parallel to the power supply. The capacitor stabilizes the voltage and slows down the degradation of the electrodes.

Precautions

When using sodium discharge lamps, it is important to remember:

- It is unacceptable to turn off power to the element immediately after turning it on. Wait at least 1-2 minutes. Failure to do so may result in complete failure to start.

- The room with the lighting element must have a ventilation system. This is due to the increased heat output of the device and the presence of harmful substances in it.

- Do not touch the lamp and reflector with bare hands while working, it is guaranteed to cause serious burns.

- It is desirable to use gloves when installing the bulb. Fat buildup when heated can cause the bulb to explode. No water should be allowed to come in contact with the exposed elements.

- The ballast used with the bulb can be heated to about 150 degrees. It is recommended that it be placed under a fireproof cover to protect it from moisture and debris.

- Do not touch the conductive parts with bare hands or allow them to get wet. It is also recommended that the wiring be inspected periodically for damage, burns or shorts. Wires in this case should be special, designed to handle extremely high voltages.

Disposal

Sodium is volatile and easily ignited by contact with the air. In addition, it contains mercury, a dangerous radioactive element that can cause serious poisoning. For this reason, sodium light sources should not simply be thrown away. They must be disposed of as potentially hazardous waste along with other energy-saving lamps.

In large cities there are bins for disposal. If this is not possible, contact your nearest lighting shop, manufacturing facility, or call a hazardous waste collection service.

Advantages and disadvantages

The sodium lamp has both advantages and disadvantages. Keeping them in mind will help you avoid unpleasant surprises.

Advantages:

- High light output compared to other lighting fixtures. For the NLVD it can be up to 150 lm/W, and even up to 200 lm/W for the NLND.

- Most of the models presented are capable of very long life, with a maximum service life of 28,000 hours.

- During operation, the efficiency parameters remain at the same level.

- The devices emit a very comfortable light for the eyes.

- Sodium lamps are able to function stably at temperatures from -60 ° C to +40 ° C.

Not without disadvantages, which include the following:

- It can take about 10 minutes from startup to reaching rated power.

- Many elements inside the bulb contain harmful mercury.

- Explosion hazards due to the likelihood of sodium coming into contact with the air and igniting quickly.

- Sometimes it is difficult to connect the control gear.

- Significant power loss (up to 60%) is observed during operation.

- Color rendering is poor.

- Significant ripple is observed when connected to 50 Hz mains.

- High voltage is required for ignition.

The disadvantages are significant, but for the organization of high-power street lighting sodium sources seem to be a convenient option.