How to make your own lighting

Make LED Strip Lighting on the power of everyone. The process does not require special knowledge and special tools, it is not difficult to do a minimum set, which is almost always on hand. The main thing - to understand the peculiarities of installation and choose high-quality components that will last a long time.

Options and uses, pros and cons

Apply LED strip can be almost anywhere, which makes this kind of versatile. But there are a few options that are used most often and provide a good result:

- Illumination of the ceiling on the perimeter. The tape is laid in a niche or behind the baseboard, which is attached with a small indentation from the surface. Due to the reflection of the light is obtained scattered, providing a uniform effect and a beautiful highlighting of the contour of the room.LED lighting can transform any room.

- Strip under projecting elements or in recesses on the ceiling ceiling complex configuration. Due to this you can highlight the original design details and emphasize them. There are different options, it all depends on the situation.A design solution with several types of lighting.

- Illumination of niches in the wall or under the furniture. This solution gives the interior a modern touch. And if you place an LED strip along the bottom contour of a bed, closet or other furnishings, it will give them a floating effect.The tape can go from the ceiling to the walls, creating an interesting effect.

- Using LED strip as the main lighting. In this case, a large-width aluminum profile is built into the ceiling, inside which several rows are glued to provide the desired intensity of light. On the outside, the element is covered with a diffuser to make the light even and soft.Multilevel backlit segments replace the basic light.

- Facade lighting and other elements of outdoor decoration or the use of tape in arbors, patios, etc. In these cases, use a moisture-proof tape in a silicone shell, which is not afraid of precipitation and temperature fluctuations.Option with illumination of the facade of the house.

- Lighting the cabinets from the inside of the kitchen. The original solution, which is often used in facades with glass inserts.

- Backlit staircase steps - This not only makes the design original, but also increases safety.Decorate the staircase in several ways: build into the railing, install it on each step or only on some of them, let it run along the entire length.

Read also: Backlighting a suspended ceiling with an LED strip

You can use backlighting and in other cases, here are listed only the main. LEDs are very popular due to a number of advantages:

- Attractive interior appearance with soft backlighting. By evenly dimmed lighting, you can achieve different effects, which expands the possibilities of design.

- Large variety of optionsand they can differ in a number of criteria, allowing you to find the right solution for any environment.

- Economical power consumption. Today it is the most energy-saving option, reducing the cost of electricity.

- Safety of use. Firstly, during operation, diodes heat much less than incandescent and halogen versions. Secondly, they do not contain hazardous substances, as in fluorescent bulbs. Thirdly, the system operates from low voltage, so there is no danger of electrocution, and you can use the tape in rooms with high humidity.

- Installing LED lighting is much easier than any other type of equipment. To understand the installation is not difficult, if you follow the instructions, the work will take a little time.

The service life of LED lighting is also much longer than that of any other analogue.

There are certain disadvantages of this type of backlighting. The main one is the high price for quality tapes, although every year it becomes less and less. It should also be taken into account that a long working life is possible only with proper installation, any mistakes reduce the resource at times.

Recommended: How to install the LED strip on the curtain rod

The varieties of ribbons used, which is better to choose

On sale there are different versions of the equipment, differing in a number of criteria. Before buying it is worth thinking through how the tape will be used and what kind is better for indoor or outdoor installation. Depending on the color there are these types:

- Single-color tapes (SMD). Suitable for creating monochromatic illumination, white versions are most often used, although they can also be colored. They differ in color temperature.Single-color tape is brighter than multi-color tape.

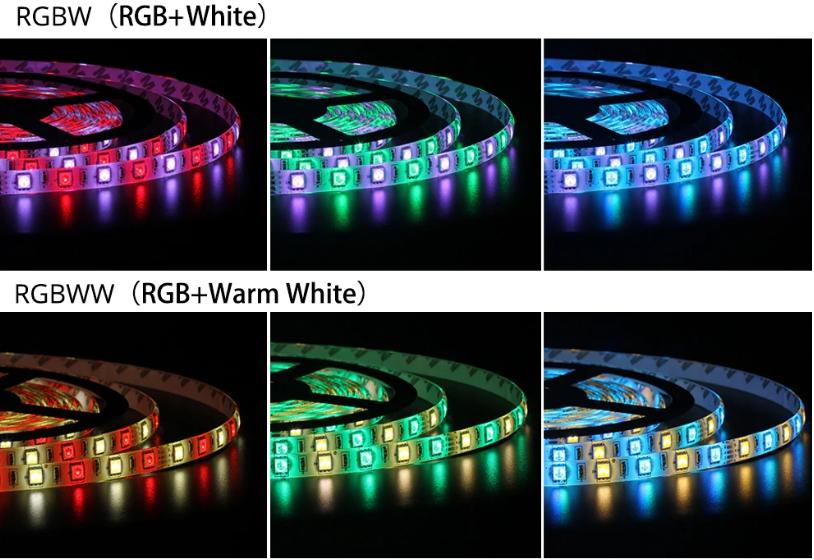

- Multicolor types (RGB).. Usually consist of red, blue and green light sources. By varying the combination of diodes, millions of shades can be adjusted. The best solution for decorative illumination.This is what an RGBW strip looks like when switched on.

- Universal strips (RGBW) consist of both colored and white LEDs. Therefore capable of producing pure white light of high quality. The products are suitable when the strip is used not only for backlighting, but also as an addition to the main lighting.RGBW has additional white LEDs, thanks to them it is possible to obtain new shades, which cannot be set on the standard strip.

The brightness of the strip depends on two factors, which is also desirable to consider:

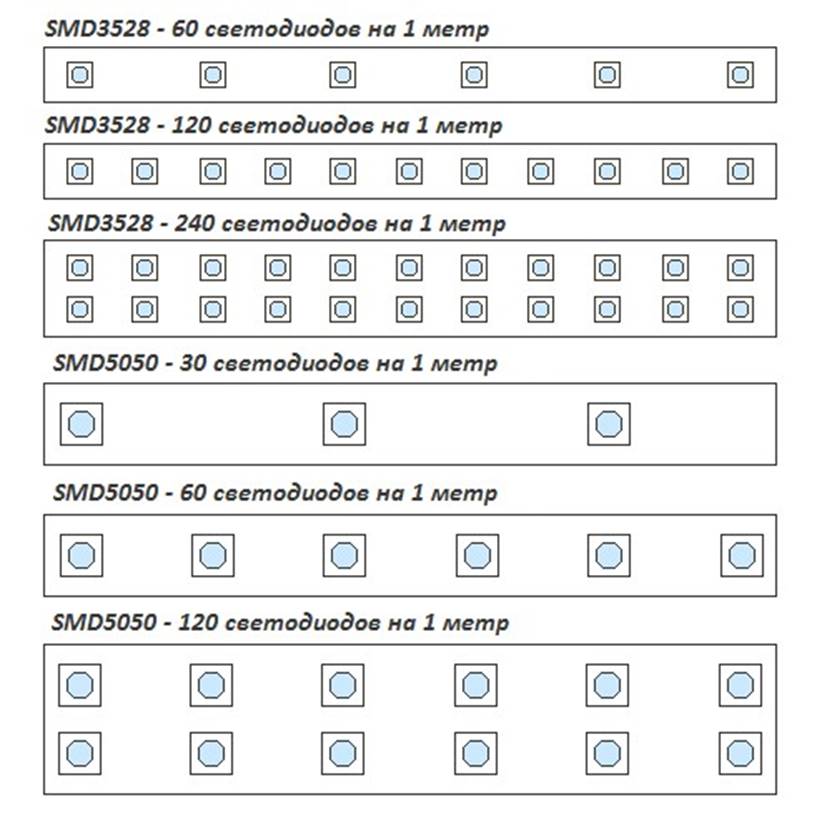

- The power of a single LEDThe total is usually dependent on the size, but is specified in the documentation or labeling. This makes it easy to calculate the total value for a strip or piece of strip.

- The number of LEDs per linear meter ranges from 30 to 280 pieces, so the brightness varies greatly. Diodes are arranged in one or two rows, their number depends on the size of each element.

The degree of protection of the tape from adverse influences. The product always has an IP marking, which prompts what the product is protected from. For simplicity, all the necessary information is presented in the table below, there is a painted value of the first and second numbers in the designation.

How to make LED lighting with your own hands

Before starting work, it is worthwhile to make preparations so as not to waste extra time. First of all, the location of the strip is determined and the total length is calculated. Usually sold in pieces of 5-15 m, but they can be cut in increments of 5 to 50 mm, the tape is always marked with a dotted line at a certain distance. You also need a power supply suitable power supply (at least 30% more power than required) and a controller if available. Wires are used for connection and aluminum profile on which glued on tape. The profile itself can be glued to double-sided adhesive tape or fastened with self-tapping screws.

For automatic activation you can use motion sensors.

How to connect the LED strip

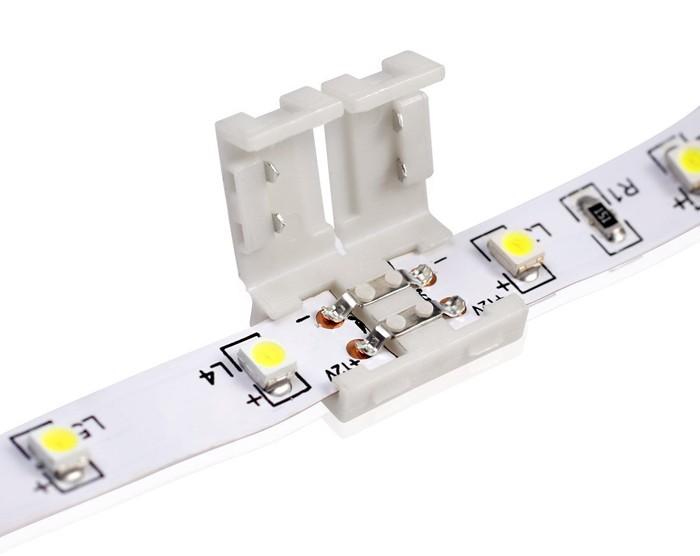

It is very important to properly fasten the strips between each other, as well as to connect the wire from the power supply or the controller, it is best to do this with a soldering iron. The instructions consist of these steps:

- Determine the length of the tape and the place of cutting, based on the characteristics of the room. It is necessary to focus on the nearest area with a dotted line.The line to cut creates a small expansion between the LEDs.

- It's best to cut it is better to cut with sharp scissors to get a clear even cut and the strip is not deformed.

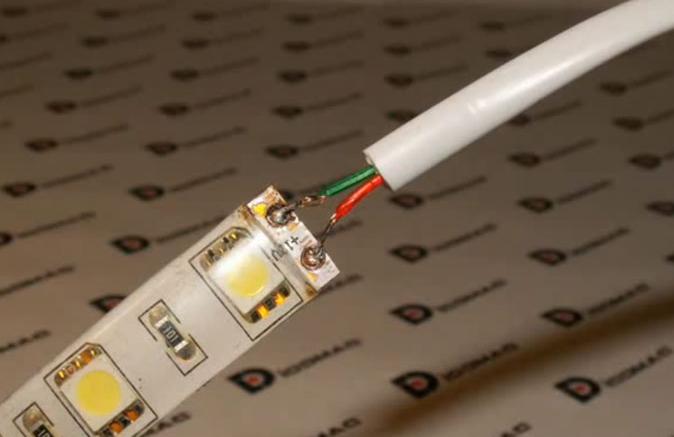

- The conductors are stripped at a distance of a little over a centimeter. You just need to open the contacts and look at the polarity, it is always marked.

- The conductors are carefully solder the wires with a suitable length and cross section. The work is done as with standard soldering.The quality of soldering is very important.

- It is best to cover the joint with heat shrink tubing. At the same time it strengthens the solder and protects it from damage.

If you use a tape in a silicone sheath, the connection is made with a special connector, and the joint is additionally treated with sealant.

Which connection scheme is preferable

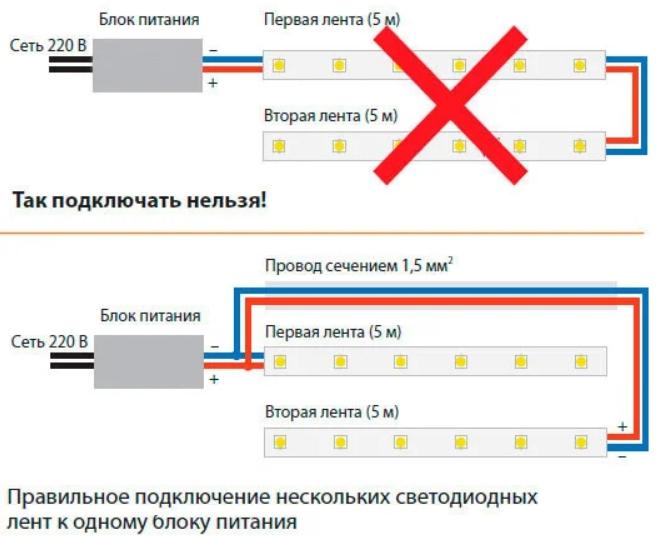

LEDs have this peculiarity: as the length of the strip increases, the brightness of the light decreases, so you should not choose a series connection scheme. Here it is important to remember a simple recommendation - with a long length, the elements are connected to the power supply in series, and the length of one piece should not exceed 5 meters in length.. For illustration, the right and wrong versions are shown.

In some cases it is necessary to connect two units, below is a diagram for this variant as well. It is important to do everything correctly to ensure a stable power supply.

It is better to connect the strip on both sides, this will reduce the load on the current-carrying tracks.

Features of installation, whether a radiator is needed

To make LED lighting durable and protect it from overheating, it is recommended to glue the strip on an aluminum profile. It effectively dissipates excess heat, preventing overheating and extending the life of the diodes.

Usually the tape has an adhesive layer on the back side, it is necessary to remove the protective film and press the element tightly to the surface. It is also worth finding a place for the power supply so that it is not visible, but still cooled normally.

Recommended to view: An interesting solution for wall lighting in the bathroom.

It is not difficult to make LED lighting with your own hands, if you choose the right circuit in advance. It is necessary to cut the element in certain places, qualitatively solder the wires and use an aluminum profile for cooling.