Types of LED strips - device and features of work

The emergence of LED lighting products has revolutionized the lighting market. And it's not just the ultra-low power consumption, compared to incandescent bulbs. Light-emitting crystals have small dimensions, so they can be combined with light sources of different shapes. Flexible devices in the form of luminous ribbons are widely used.

How is the LED-tape and the principle of its operation

The principle of operation of ribbon, as well as any LED-lighting, based on the ability of semiconductor p-n junctions emit when passing current. The frequency of radiation may lie in the infrared, visible or ultraviolet range. In this way it is possible to get a monochromatic glow, but not the white color, which is a mixture of colors of the visible part of the spectrum. A breakthrough was the development of LEDs in which the light-emitting component was a coating of phosphor material. Its luminescence is initiated by p-n junction radiation, which need not be visible (usually UV light). This dramatically expanded the field of application of LED lights and with this began their triumphant spread.

The popularity of flexible lights is based on the possibilities of their application. Such a device can be mounted in a variety of places with any configuration. The device LED strip is not complicated. On a flexible base of varying thickness are applied groups of LEDs with quenching resistors or with addressable microcircuits. Along the webbing go power buses, on both sides ending with contact pads. On the other side, many manufacturers apply an adhesive layer to simplify installation ..

The webbing can be cut in the specified places, forming sections of the required length. Group diagrams, LED types and resistor ratings set the characteristics of the luminaire and its application area.

Where are the applications of luminaires on a flexible basis

The field of application of LED tapes can be divided into two large sectors depending on the device of the luminaire:

- Illumination of streets and interiors. For this purpose, LEDs are mostly used in white emission color. You can choose fixtures with a warm (red-yellow) spectrum, they are used in living rooms for bedrooms, living rooms, etc. Devices that emit in a neutral spectrum are used for outdoor lighting and in industrial premises, as well as in living rooms, kitchens and public facilities. In museums and jewelry salons, cooler shades of white are more appropriate. It is convenient to use segments of the LED strip to create local illumination.Example of exterior lighting of the doorway of a balcony.

- Decorative building lightingThe RGB ribbons are widely used to dynamically change the color of illumination. Here are widely used RGB ribbons that allow you to dynamically change the color of the glow. Any boundaries in the creation of lighting effects ceased to exist after the appearance of fixtures based on addressable LEDs.Decorative illumination of a building with RGB-lighting.

For each area of use, you can choose the luminaire that best suits the capabilities and cost.

How to label LED-lights

The adoption of a unified system for labeling LED tapes has long been overdue, but manufacturers of lighting equipment are in no hurry to agree among themselves. Therefore, there are several different parallel ways to summarize the characteristics of LED strips. The most informative is labeling of the form RTW 2-5000PGS-12V-DayWhite 2x (3528, 600 LED, W). Deciphering is given in the table.

| RTW | Sealed tape with frontal glow |

| 2 | Factory series |

| 5000 | Total coil length in mm |

| PGS | Sealing method (silicone shell filled with sealant) |

| 12V | Supply voltage |

| DayWhite | Color of light |

| 2x | Double density of light-emitting elements |

| 3528 | LED form factor |

| 600 LED | Total number of LED |

| W | LED backing color (W-white) |

In this system, there are at least two important parameters, without which the choice of lighting fixture is difficult

- power consumption per meter of ribbon (it can only be estimated by the size of LEDs used and their mounting density);

- degree of protection (here, too, you can make a rough estimate on the method of sealing).

But this marking looks the most suitable for adoption as a standard, or at least the basis for it.

Video block will complement the above.

Variety of types of LED strips

Competition in the market of lighting equipment makes manufacturers close all niches of LED devices, and even create new ones. This is done by producing varieties of illuminators that have no analogues and prototypes in earlier developments.

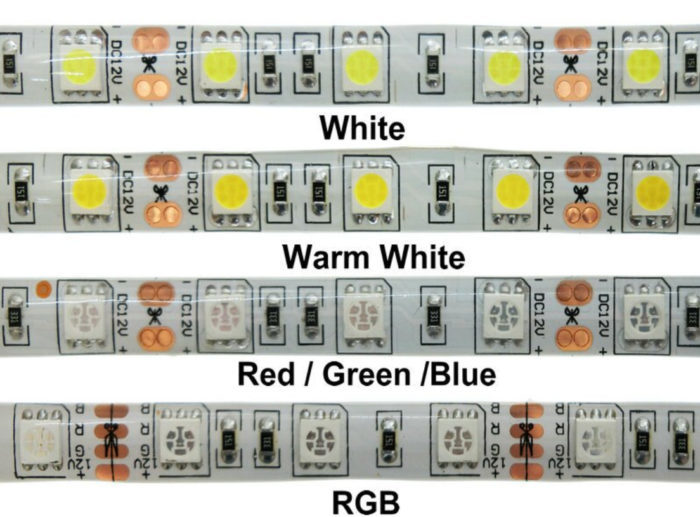

By color of radiation

Monochrome strips

With the development of LEDs with white color emission, LED-equipment is no obstacle to the full conquest of the market. But even white light is not the same, and has a gradation on the spectrum of radiation, characterized by color temperature (in Kelvin).

The consumer can choose from warm red-yellow shades to cool blue-violet shades. It is also possible to buy monochrome lights with colors other than white. Their labeling includes the color name in English (Green, Blue, etc.).

RGB lights .

This type of ribbon contains three LEDs red, green and blue. It makes it possible to get a glow of almost any color by mixing in different proportions of the three basic shades. And this glow can be changed dynamically. Designers have almost unlimited potential to create architectural lights, visual effects, etc. Such devices are marked with RGB symbols and controlled by controllers (industrial or amateur design).

The only limitation of such fixtures have on the white color - it is impossible to get pure white from the three primary colors. For cases where this is critical, one white LED is added to each of the three colored LEDs. It "tints" the synthesized white color. This strip is marked with the letters RGBW (RGB+White).

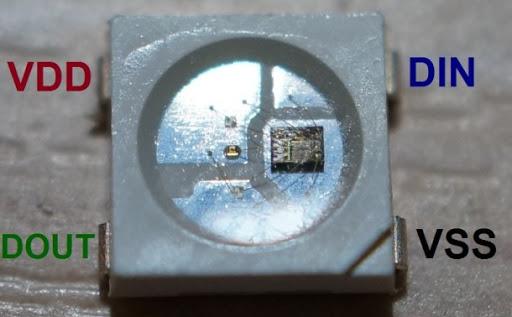

Luminaire based on the addressable LEDs

This type of LED-tape has no analogues in the world of lighting technology and has a limitless multimedia component. Its main difference from conventional RGB-tape is that it is available to control the glow of each tri-color element separately. Luminaires with SPI bus can be controlled by industrial consoles, for devices with single-wire bus (for example, based on WS2812b elements) microcontroller-based control circuits are used (including those on the Arduino platform). This allows you to fully exploit the possibilities laid down by the developers.

Variety by design

Conventional LED strips have a degree of protection IP20. This means that the device is protected from solid particles larger than 12.5 cm and is not protected from water at all. This design does not allow the illuminator to be used in an open space, not to mention wet rooms. Therefore, special types of tapes with additional protection are produced:

- in the form of a transparent silicone tube put on the cloth - the marking has the designation P;

- the cloth can be filled with transparent sealant - marked with the symbols SE;

- if both methods of protection are present (the silicone tube is filled with sealant), in the marking there are symbols PGS.

These methods of protection allow the production of LED-lights with a degree of protection up to the highest (IP68) and the use of strips even under water.

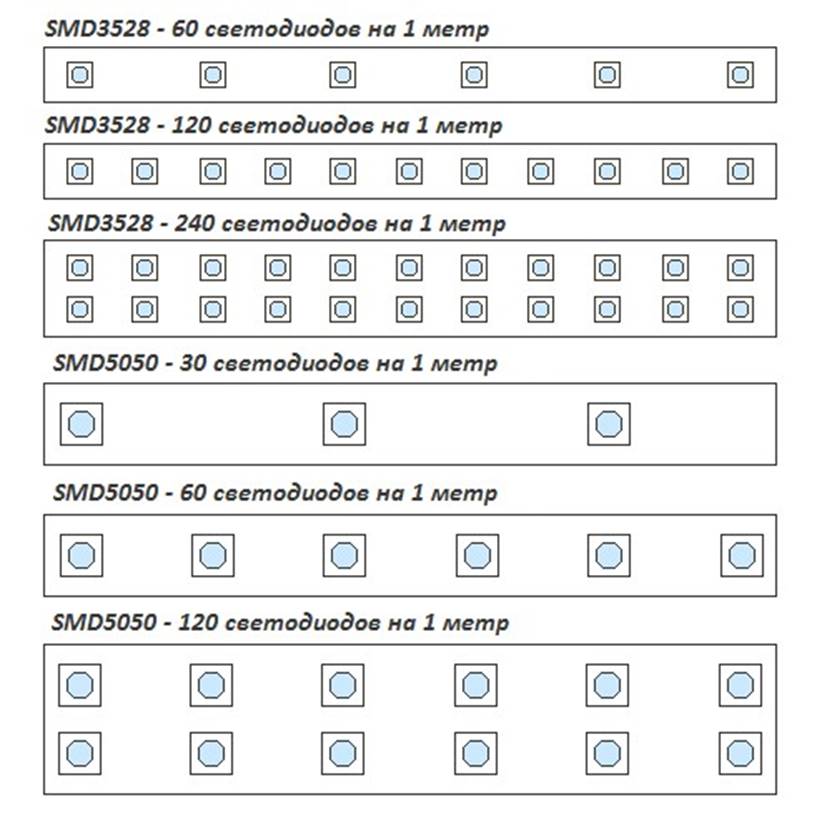

By the light-emitting elements used

To form the light output of LED-lights are different types of LEDs, including the body cylindrical. But the most widely used ribbons are based on leadless elements (SMD). This design is the most technologically advanced in manufacturing and allows to reduce the cost of lighting equipment. LED form-factor is marked with four numbers indicating the size of the element in terms (length and width). These symbols are usually included in the marking of the ribbon.

| Type of light-emitting element | Dimensions, mm |

| 3528 | 3,5 х 2,8 |

| 5630 | 5,6 х 3 |

| 5050 | 5 х 5 |

| 5730 | 5,7 х 3 |

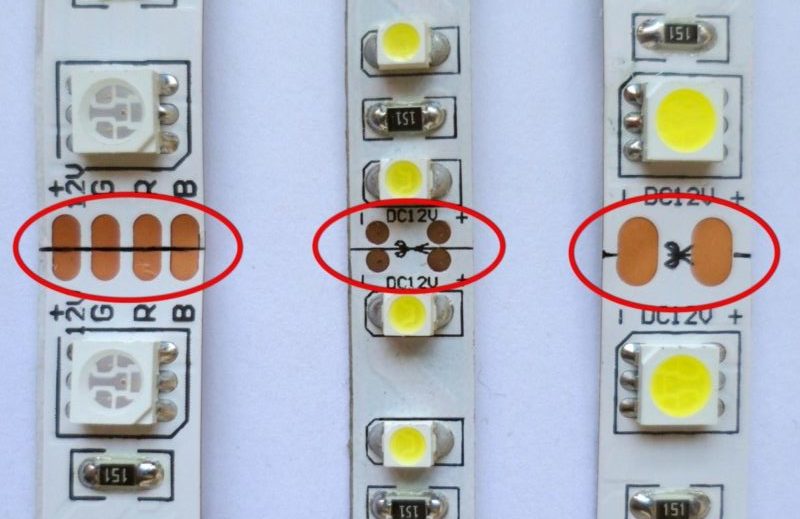

For RGB strips the following LEDs are used LEDswhich contain three crystals with different emission colors in one housing. They are separately controlled, but their anodes are connected. Typically, these elements are also used in a pinless design.

To create addressable strips use miniature PWM drivers, which can be embedded light-emitting p-n junctions. But also widely used chips with external connection of three LED base colors (or LED matrix in a single package).

Power consumption

The LED consumes electrical power to create light flux. Although LEDs have a much higher ratio of this power to light intensity than incandescent bulbs, strip lights can draw a significant amount of current. It is determined by:

- The power consumption of a single element (depends on its type);

- The number of LEDs installed on the strip (depends on the density of the arrangement).

In practice, it is important such a parameter as the power consumed by one meter of tape. When calculating the lighting system is guided by this characteristic. The most common labeling for this parameter has no place, but some manufacturers take it seriously. For example, one of the strips manufactured under the brand Apeyron, is designated as Apeyron Electrics LSE-159 SMD 5050 30LED IP20 12V 7,2W 5m. Here, 7.2W is the specific power consumption.

Light directionality

In most cases, the light flux is directed across the plane of the leaf. But there can be a situation where you need to illuminate a surface, and it is problematic to place the strip strictly over it. Or it's necessary to avoid a situation where the light hits a person in the eyes. Then use the tape side glow - it has LEDs main stream is directed along the plane of the cloth, that is, along the surface to which the tape is glued.

Such LED-tape in the most common labeling is denoted:

- RS - in open version;

- RSW - in sealed version.

Gluing such a light on the wall, you can to illuminate the stepswithout blinding people.

How to connect the LED-tape

LED lights on a flexible basis on the connection method fall into several categories:

- Monochrome . 220 В. They are connected to the mains via a rectifier device.

- Monochrome low voltage. This category includes LED lights for operating voltage of 5/12/24/36 volts. It is best to power them from power supply units for the appropriate voltage. If the strip is used in a car, it can be connected directly to the on-board power supply.

- RGB LED lights. To fully realize the possibilities such LED strips are powered from a source of appropriate voltage, and controlled by an industrial or homemade controller. You can turn on a permanent glow, but there is no economic sense - monochrome strip is cheaper.

- Luminaires based on addressable elements. The voltage to the power rails is supplied from a separate source, the control is done only through the controller - there is no other way.

Topical video: Everything you wanted to know about LED strips.

The versatile types of LED strips allow you to implement almost any lighting options for any purpose. The decision on economic and aesthetic feasibility is always up to the user.