Manufacturing of controller of low beam headlights

Traffic regulations require that the car in the daytime be equipped with daytime running lights (DRL, foreign designation - DRL). Not every car has them by design, so the role of DRLs is often performed by the lights included in the standard equipment of the car - fog lights, dipped beam headlights, etc. Some motorists install homemade DRLs on vehicles. To control them, you need a separate device - a controller.

What is a controller for DRLs

Controller DRLS - An electronic system that controls the glow of the DRL. Its functions may include:

- automatic activation of daytime running lights - a basic and mandatory service;

- On and off DRLs depending on the voltage on-board power system of the car;

- stepless supply voltage to the DRLs - if they are used incandescent dumps, it can increase their life;

- adjusting the brightness of the lights (manual or automatic).

Other service functions are also possible - everything is limited only by the designers' imagination.

Manufacturing instructions

The daytime running lights control unit can be purchased. And you can make it yourself. There are several schemes of different control units for daytime running lights - depending on the availability of components and skills of the master, you can choose the best option.

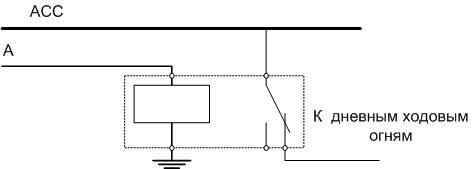

Controller DRLs based on a relay

The simplest DRL controller can be assembled on a single relay. True, and the functions it will perform only basic:

- turning on the sidelights when the ignition is turned on;

- Lights turn off when the starter;

- switching off the DRL when the low beam/mid beam, lights, fog lights are on (a slight complication may be required).

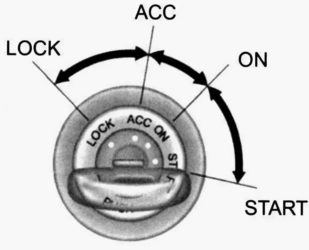

The controller operation is tied to the ACC key position (accessories) in the ignition locks of many cars, designed to turn on the auxiliary equipment (car audio, cigarette lighter, etc.). The lock has a separate output (a wire with a large cross section is connected to it), there is voltage on it when the ignition is turned on, but not when the starter is on. This algorithm correlates well with the conditions of DRL switching on, so it is convenient to use this wire for switching on the DRLs.

When voltage appears on the wire A, the relay is triggered, the contacts open and the DRLs turn off. The connection of this conductor depends on the circuit of the car electrical equipment. The voltage can be selected as an extinguishing signal:

- switching on the fog lights;

- low or high beam;

- lights.

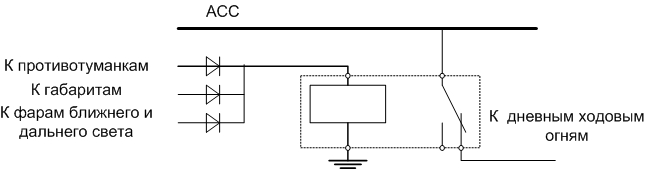

If the scheme of the car's lighting equipment is built so that a separate wire (which is then branched off) goes to the regular lighting, then you can use it. If this is not possible, there are two options:

- Apply only one signal (only high beam, only fog lights, etc.) to extinguish the DRLs;

- combine all necessary signals with diodes (OR circuit).

In the latter case the circuit will be a bit more complicated - you will need several diodes according to the number of signals by which the DRL should turn off.

In this scheme, the inclusion of any specified light equipment will trigger the relay, opening contacts, de-energizing the DRLs.

Important! It is obligatory to use diodes for decoupling. In their absence, turning on one of the equipment will turn on the other light sources.

Specific connection points will vary from car to car depending on the scheme and topology of the on-board network. There is no need for a separate enclosure to accommodate this variant of the control unit. The relay can be placed in any convenient location. If diodes are needed, they can be soldered directly to the relay coil pin.

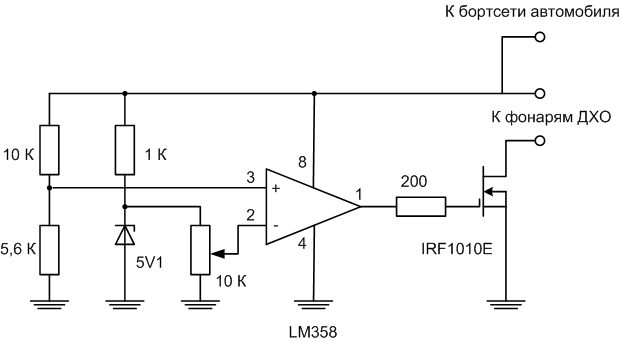

With a comparator

You can find a comparator controller diagram on the Internet. Its operation is based on the monitoring of the on-board voltage. With battery power it is about 12 volts, and with the engine running and power from the generator about 13.5 volts. When the voltage crosses the threshold, the comparator will switch the lights on or off via the power switch. The turn-on level is set with a trimmer resistor.

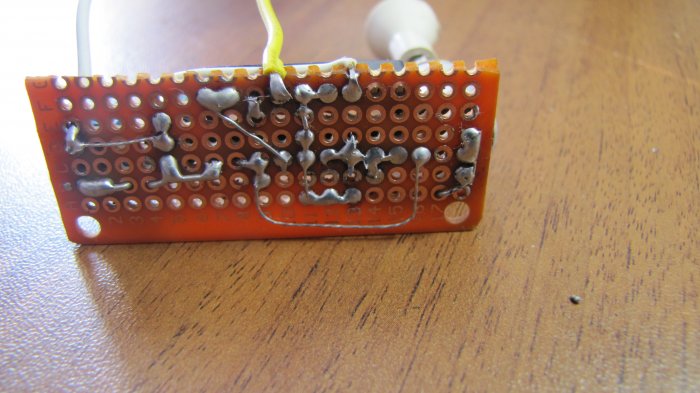

The problem here is that the DRLs should not turn on when the motor is running, but when the ignition is turned on. And this moment is not tracked in this circuit. But if someone wants to build it, it can be made as a module. The electronic components and the connector for the connection must be placed on the board and put it all in a housing. Preferably a metal one. Those who know how to make printed circuit boards at home (LUT, photoresist) can design and etch the board. The rest can assemble the circuit on a piece of breadboard. The unit is installed in a convenient place and connected according to the diagram.

Using the ATmega8 board

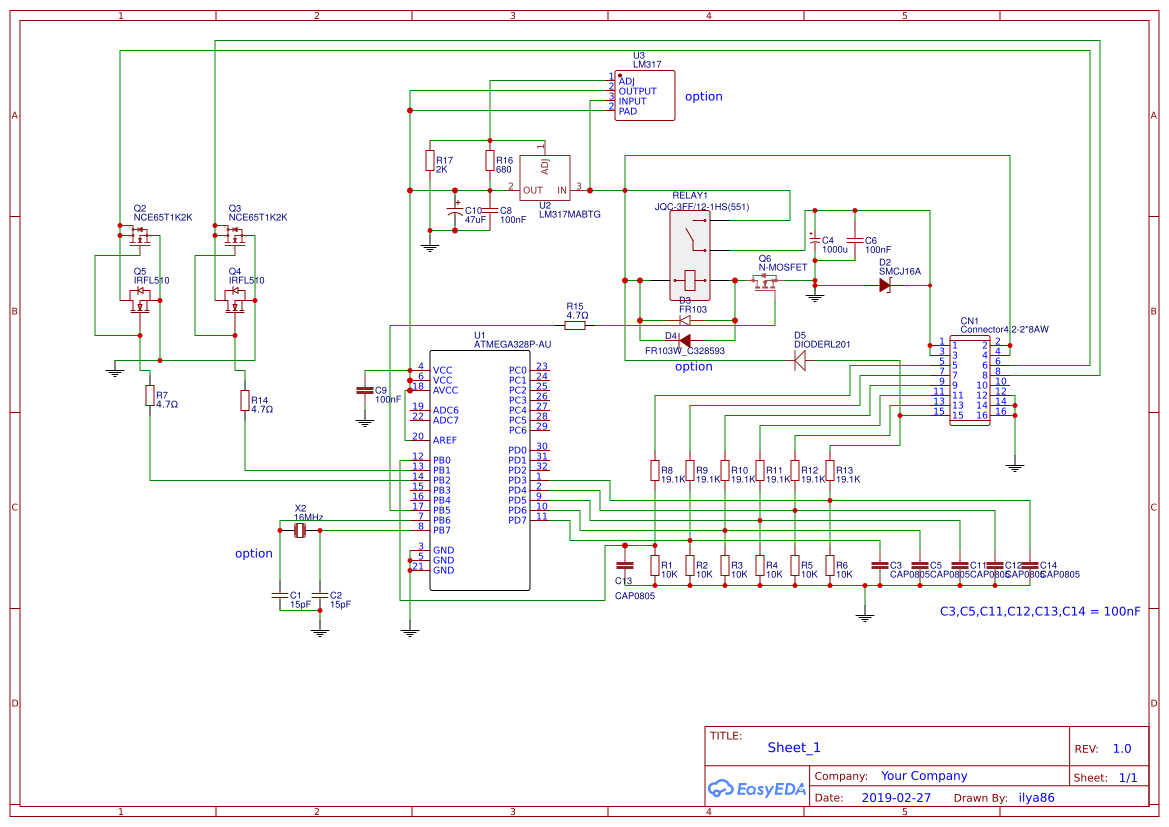

Many motorists design their own controller schematics for their own needs and put the materials on the internet. Here is one of the variants on the popular ATmega8 microcontroller. Its use allows you to greatly expand the functionality of the control circuit.

When the ignition is turned on the board is powered and the controller waits for the engine to start. When the start signal is received the control circuit checks the operation of one of the turn signals. If at least one turn signal is on, the brightness of the running light on the corresponding side is reduced. The level of illumination is controlled by pulse width modulation. Also the switching on of the dipped beam is monitored, the presence of this signal is also the reason for switching off the parking lights. The switching on of fog lights indicates bad weather conditions, so the brightness of the DRLs, on the contrary, becomes maximum when the dipped beam is on. If the hazard lights are on, the DRLs blink in counter-phase with them. And there is also a very useful function - If the ignition is off and the dipped beam is left on, the running lights start blinkingto remind you that the battery might run out.

In this case the controller also does not switch on the lights when the ignition is on, but waits for the engine to start. But this defect is not hard to fix programmatically (you can ask the developer for it). Connection and assignment of the board pins to external circuits are given in the table below.

| contact number | designation | Function |

|---|---|---|

| 1,3 | LED+ | DRL power line (output) |

| 2,4 | VCC | Circuit board power supply |

| 6 | Lled | Left light |

| 8 | Rled | Right light |

| 5 | lbm | Middle beam |

| 7 | fog | Fog light |

| 9 | Rin | Right turn signal |

| 11 | Run | Signal from alternator |

| 13 | Lin | Left turn signal |

| 15 | Ign | Ignition |

| 12,14,16 | GND | Common wire |

You can download the firmware for ATMeg. It is better to assemble the controller on a printed circuit board and the use of SMD-elements will greatly reduce the size of the module. This design is intended for qualified specialists, so it won't be hard to design and make a printed circuit board for them. You can also find many other hobby designs for DRL control with other microcontrollers, including the popular ATTiny13. The functionality of the devices depends on the capabilities of the chip and the imagination of the developer.

What you need to make

To make a simple dcho controller with your own hands, you will need a relay. You can use any 12 volt car relay with a normally closed or change-over contact group. The advantage of such a relay is its closed design. The casing does a good job of protecting the inside from external influences (water, dirt), so no additional measures are necessary, and the relay can be installed in any convenient place. If a different relay is used (any model for the appropriate voltage with the appropriate contact group can be used), additional protection measures have to be taken.

The diodes can be any of the 1N400X series or others of suitable dimensions. In terms of voltage, almost any semiconductor device will pass, in terms of current - to be enough to trigger the relay.

For more complex circuits, you will need the electronic components shown in the schematics (any operational amplifier suitable for the supply voltage can be used as a comparator), as well as a board for the assembly. For microcontroller firmware you will need a programmer.

How to properly install the controller on the car

First of all it is necessary to find an electrical scheme of the car and thoroughly understand it. It is necessary to determine to which circuits the homemade controller should be connected. Then you should determine the points where it is more convenient to connect (not all circuits are easily accessible, to access some you will have to disassemble part of the car, remove panels, etc.).

Read also: How to choose the right running lights on the car, so as not to get fined

The next step is to determine the routing of wires from the connection points to the controller terminals. It's hard to give specific advice here - the scheme and design of electrical equipment in different cars may differ a lot. When this question is clear, you can choose optimal place for controller board installation. It must be protected as much as possible from high engine temperature, water or dirt ingress. The last factor can be eliminated by putting the controller board in the case, but the shell must not prevent the cooling of the electronic key transistors. Therefore, the beautiful-looking option of putting the board in a heat shrink is not a good idea.

The power circuit going to power the front panel must be equipped with a fuse for the appropriate current regardless of the version of the controller.

Recommended: Video assembly of a simple DRL CONTROLLER.

If you decide to make your own DRL controller, you should immediately realize that the manufacturing and installation process is creative. Ready-made tips are not easy to find because of the difference in the design of the car. It is necessary to be ready to make technical decisions. If this is not intimidating, you can proceed to the selection of the circuit and fabrication of the device.